Construction method of temperature decrease and crack prevention of mass concrete by utilizing thin-walled corrugated pipe circulating water system

A technology of circulating water system and construction method, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of insignificant cooling and anti-cracking effect of large-volume concrete, unguaranteed quality of joints, labor-intensive transportation and connection Time-consuming and other problems, to achieve the effect of significant cooling and anti-cracking effect, low cost, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

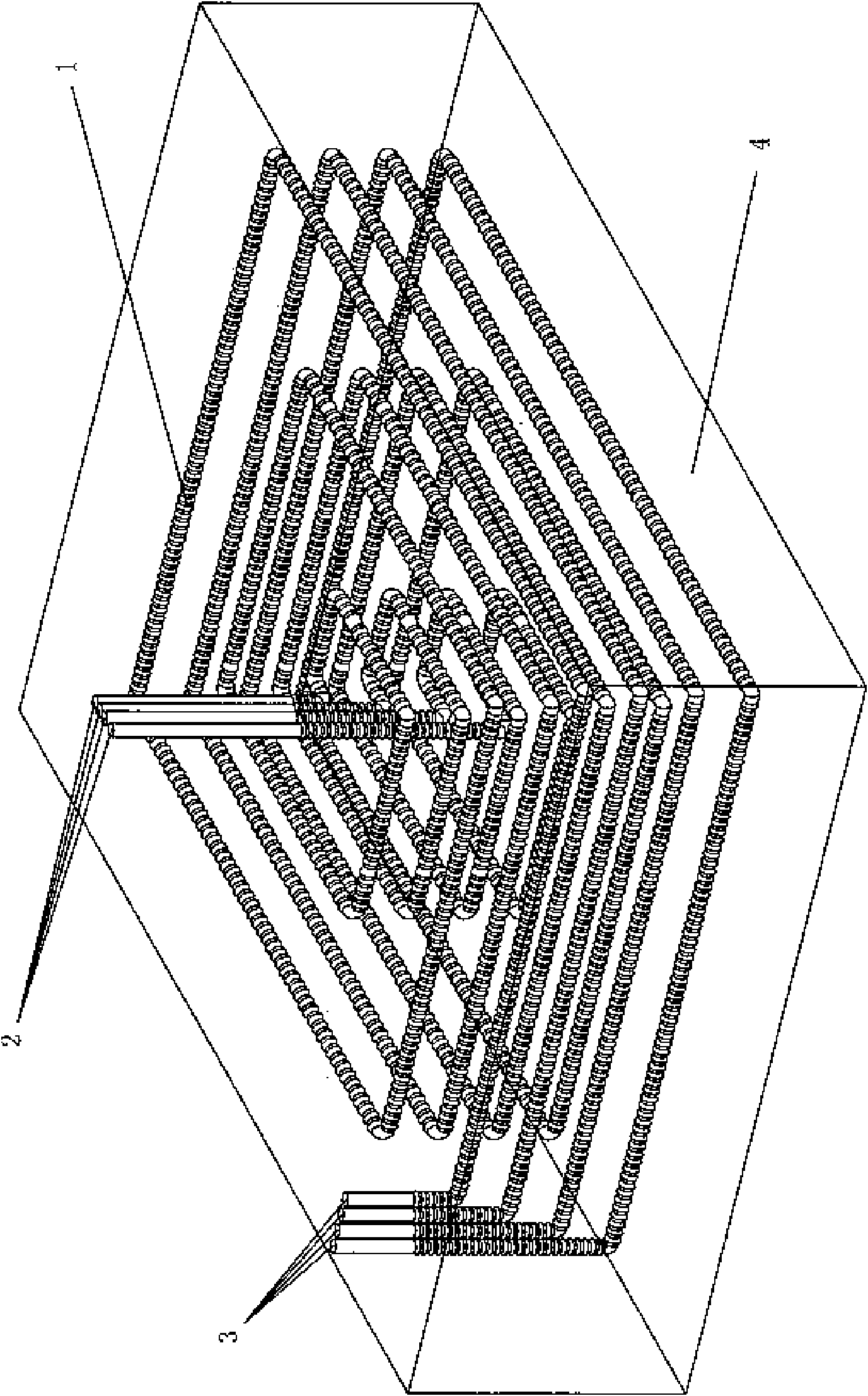

[0018] see figure 1 , the construction method of a large-volume concrete cooling and cracking resistance using a thin-walled bellows circulating water system described in this embodiment is characterized in that it includes the following steps:

[0019] (1) Select the material of the circulating water pipe: choose the thin-walled iron corrugated pipe 1 as the pipe material for laying the circulating water pipe; the inner diameter of the small circular section of the corrugated pipe 1 is 30 mm to 100 mm; A steel pipe with a cross-sectional shape composed of troughs, crests and transition curves along the direction perpendicular to the length). The steel pipe can be formed by one-time cold pressing, or it can be formed by spiral bending and rolling of long iron strips. Compared with straight steel pipes (or round-section steel pipes), under the condition of equal length (or equal cross-sectional area), it has a larger contact area with the outside world; the corrugated pipe 1 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com