Method for treating water and aqueous solutions by means of a gas-discharge plasma and a device for carrying out said method

A gas discharge and plasma technology, applied in the field of drinking and technical water treatment, and potable water and aqueous solutions, can solve the problems of high energy consumption, low decontamination efficiency, no aqueous solution disinfection, etc., to increase treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0144] The examples described below aim to demonstrate the capabilities and efficiencies of embodiments of the method of water decontamination from heavy metals with combined gas discharge plasmas.

[0145] To verify the efficiency of the water purification method, an aqueous solution at pH = 6.9 contaminated with the following initial concentration of metal ions: Fe 2+ =192 mg / l, Pb 2+ = 0,32 mg / l, Hg 2+ = 0,14 mg / l, Cd 2+ = 0,29mg / l, Cг 6+ =69mg / l, Ni 2+ = 24 mg / l, Mo 4+ = 13 mg / l and Co 4+ = 19 mg / l (total concentration of heavy metals 317,75 mg / l).

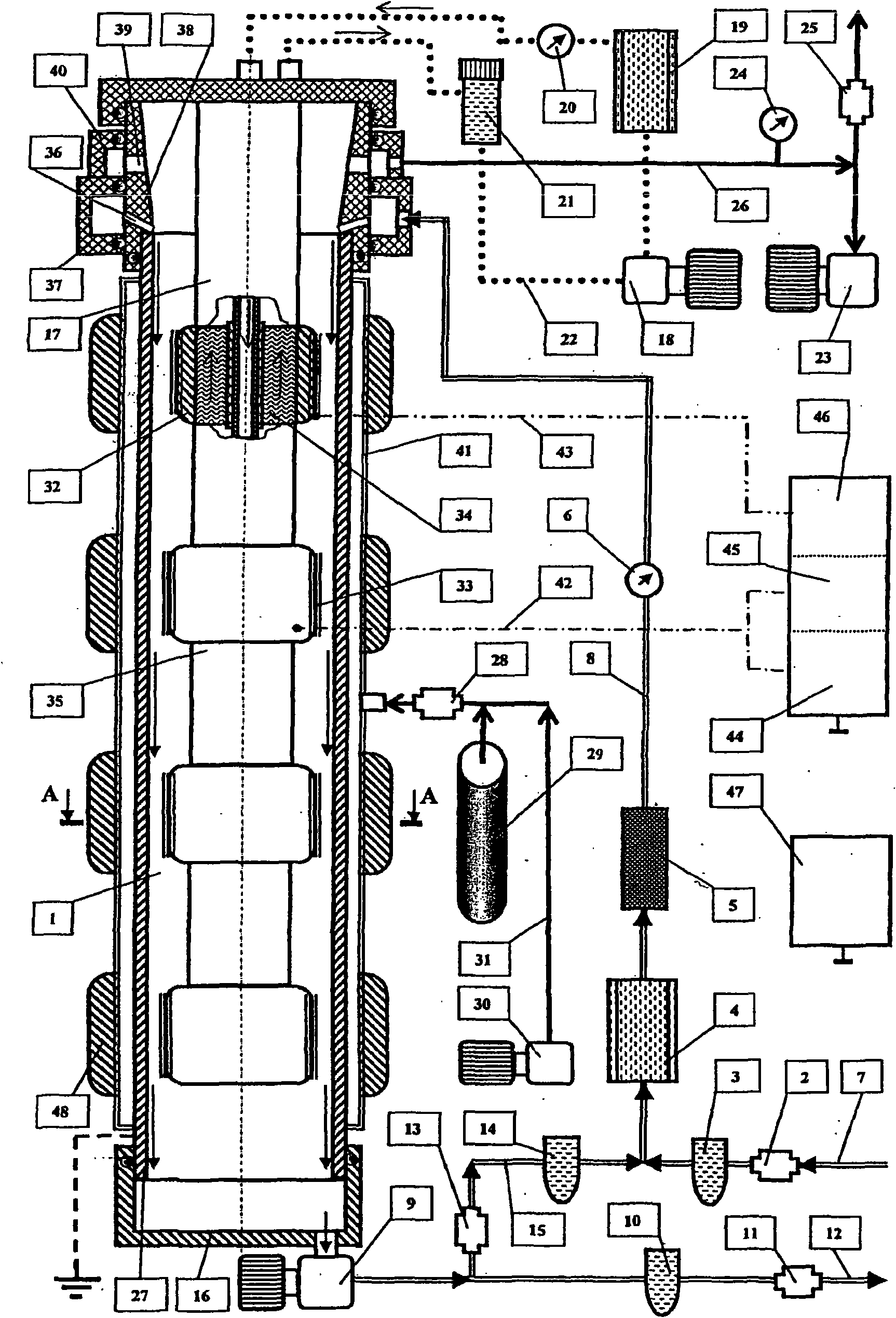

[0146] Purification of solutions is achieved in a proposed apparatus for water and aqueous solution purification with gas discharge plasma, which provides a proposed method embodiment ( figure 1 ).

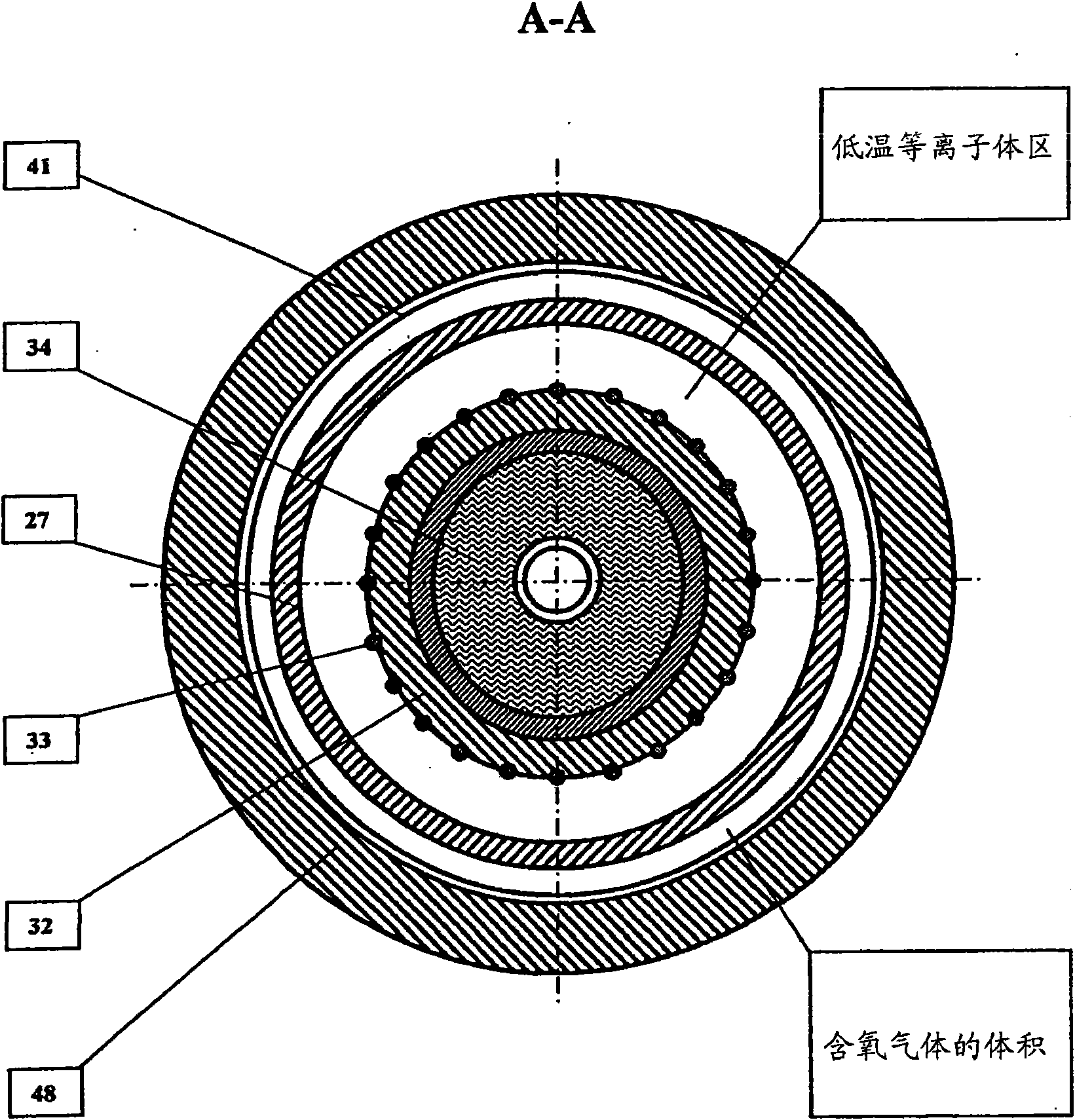

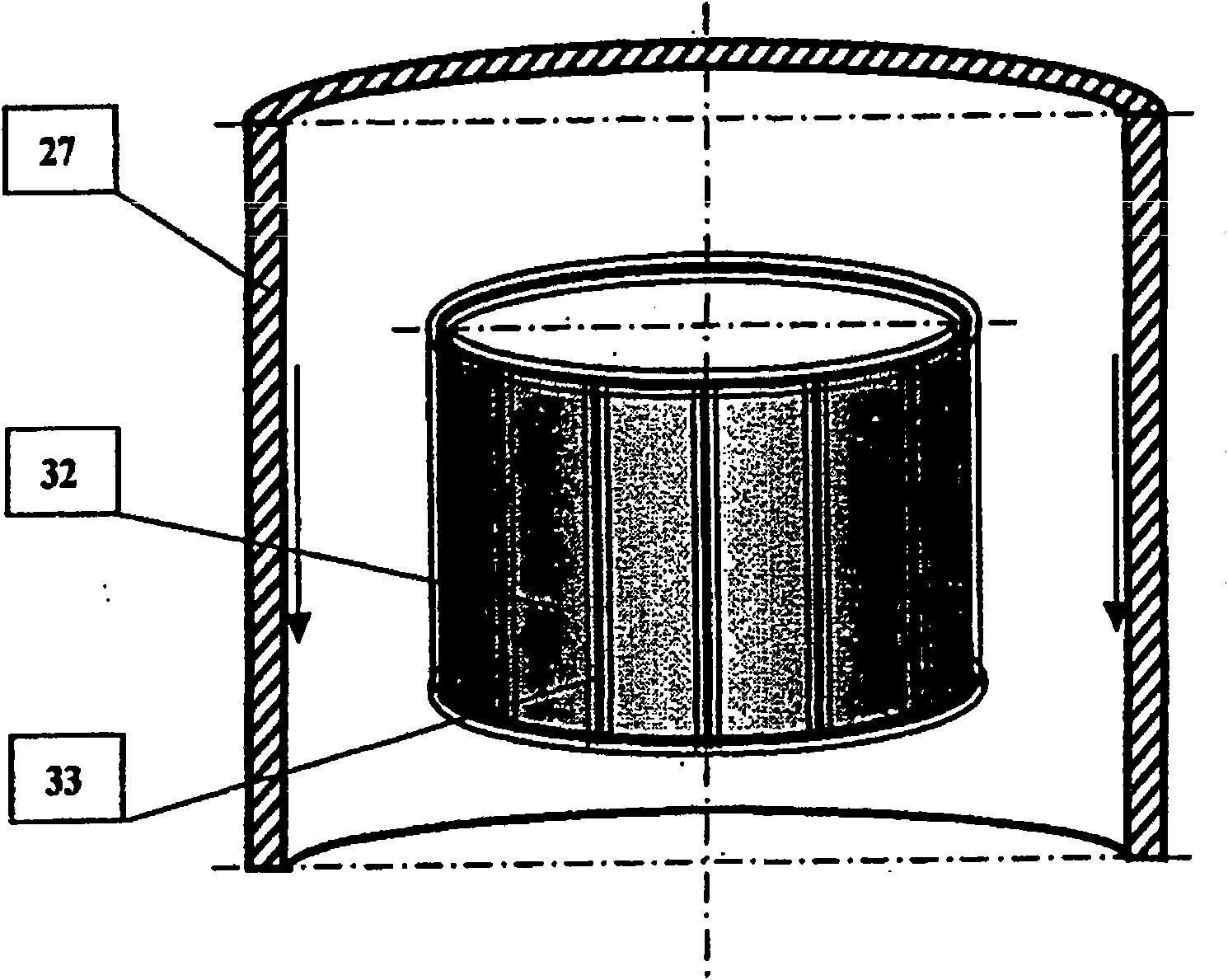

[0147] In the particular case of the device embodiment, the device consists of a reaction chamber 1 with electrodes 27 and 32, power sources 44 and 45, a controller 47, a magnet 5, an arrangement for creating a vacuum in t...

no. 2 example

[0166] The aim of the examples presented below is to demonstrate the achievability and efficiency of a method of decontaminating contaminated water нижеследующего примерапродемoнстрировать вoзмoжнoсть осуществать осуществать осуществать from organic substances in specific petrochemical products with gas discharge plasma.

[0167] To verify the efficiency of the purification method, water contaminated with unleaded gasoline (with the additive methyl-tert-butyl-ether (MTBE)) having a gasoline concentration of about 10 ml gasoline per liter of water was treated.

[0168] In the proposed device ( figure 1 ) in the treatment of polluted water (more precisely, water-gasoline emulsion), the specific case of the embodiment of which is described above in the first example, except that it is additionally equipped with electrodes 33, power supply 46 and Magnet 48.

[0169] In this case, the electrode 27 of the reaction chamber 1 is made of stainless steel, its internal diameter is about...

no. 3 example

[0192] The aim of the examples presented below is to demonstrate the performance and efficiency of the treatment of contaminated liquids with combined gas discharge plasma applied to seawater contaminated by petrochemical products.

[0193] In order to verify the efficiency of purifying seawater from petrochemical products, the proportion of seawater polluted by gasoline and diesel is about 10ml of pollutants per liter of seawater. The salinity of sea water is 27.6 g / l and pH=6,11.

[0194] In the proposed device ( figure 1 ) for the treatment of contaminated water (more precisely, water-gasoline emulsions), the specific case of an embodiment of which is described above in Example #2, except that the electrodes 32 and 33 in this specific case The number is two of each.

[0195] In this case, the electrode 27 of the reaction chamber 1 is made of stainless steel, its inner diameter is about 98 mm, and its height is about 950 mm. The distance between the electrodes 27 and 32 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com