Method for manufacturing Tianfu brick tea

A production method and technology of Tianfu bricks are applied in the direction of tea treatment before extraction, which can solve the problems of long flowering period of Fuzhuan tea, poor tightness of brick body, small particles, etc., and achieves bright color, remarkable health care effect, The effect of delicate raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

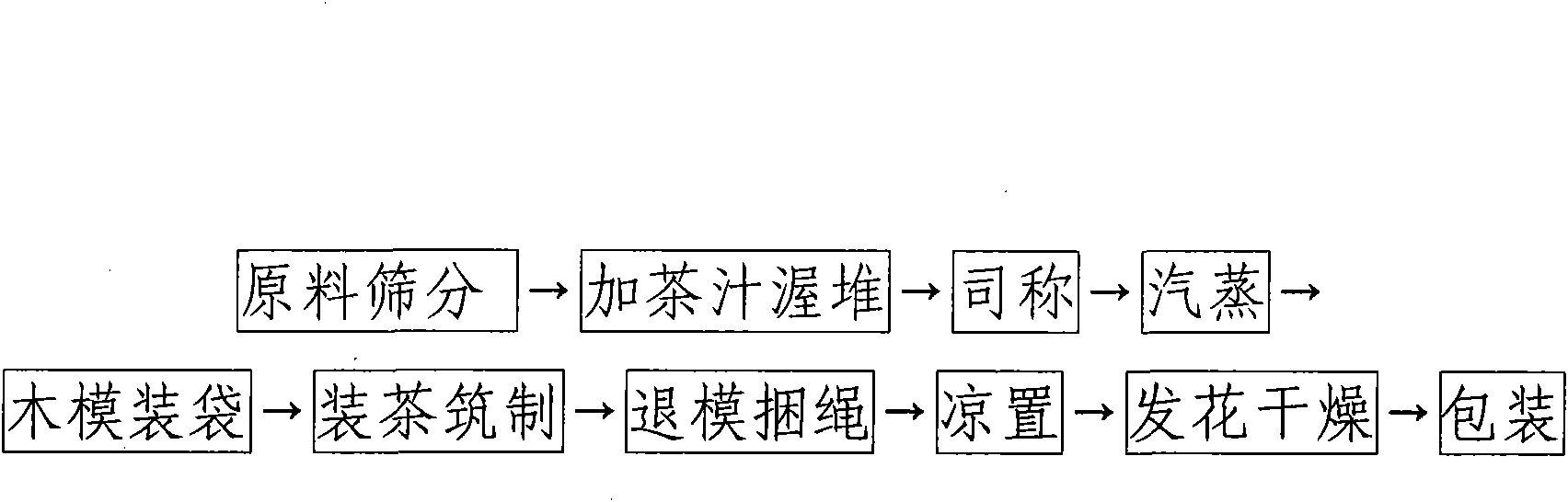

[0012] Embodiment one: the preparation method of Tianfu brick tea is as follows figure 1 As shown, the process includes: raw material screening→adding tea juice and stacking→weighing→steaming→wooden mold bagging→packing tea and pressing→removing the mold and tying rope→cooling→flowering and drying→packing. Raw material screening: After the raw materials are out of the warehouse, the body and color of the tea leaves are screened out through a round sieve and a flat round sieve. Add tea juice and heap: according to different seasons, add 10-20 catties of tea juice boiled with steam for every 100 catties of tea leaves, mix well, pile up, ferment and ferment for 12-24 hours, so that the water content of the tea leaves reaches 20-22% . The company said: According to the water content of the tea leaves, consumption and other factors, 1 kg of Tianfu brick tea requires 1.1-1.4 kg of materials to be weighed and poured into the tea steaming box. Steaming: Use the heat and humidity of ...

Embodiment 2

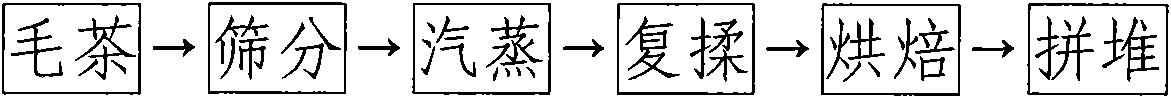

[0013] Embodiment two: include additional process in the raw material screening step of embodiment one, other steps are with embodiment one. Raw material screening additional process such as figure 2 Shown: raw tea→sieving→steaming→re-kneading→baking→stacking. Screening: Pass the first-grade black hair tea through the screening production line to separate out the tea dregs of each design and color. Touzi tea must be re-kneaded, baked, and then sieved. Steaming: Touzi tea is packaged according to the weight of 25-35 catties / bag, and steamed for 3-4 minutes at a steam temperature of 110-120°C. Re-kneading: After the tea is steamed, take out the tea bag, pour it into the tea kneading barrel, cover the pressing plate, turn on the machine and knead. After 5 minutes, open the tea outlet plate of the kneading machine, so that the kneaded tea leaves can be released while unblocking until the tea leaves are exhausted. Baking: The tea leaves are evenly spread, and the amount of roas...

Embodiment 3

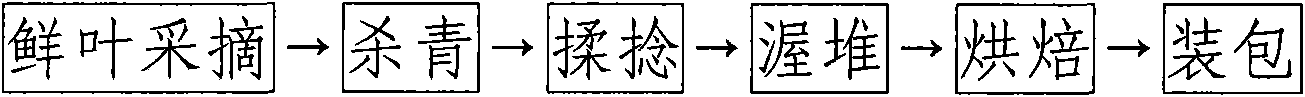

[0014] Embodiment three: be provided with the primary processing step of dark tea raw material before the raw material screening step of embodiment two, other steps are with embodiment one and embodiment two. The primary processing steps of dark tea raw materials are as follows: image 3 Shown: picking fresh leaves→cooking→kneading→stacking→baking→packing. Picking of fresh leaves: The fresh leaves of first-class black hair tea are one bud, two leaves and three leaves. Insect leaves, missing leaves, diseased leaves, and rainwater leaves cannot be used. Greening: After the fresh leaves are spread out for a while, the greening is carried out. The temperature of the greening pot is 200℃~300℃. When the aroma changes from a green smell to a light fragrance, it can be out of the pot after the greening is completed. The greening must be thoroughly killed, and the scorched leaves and edges cannot appear. Kneading: The finished leaves must be kneaded by heat. When kneading, grasp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com