Method for performing construction operation on large-area ultra-soft soil site and steel frame system used by same

A super-soft soil and large-area technology, applied in the field of steel frame systems, can solve the problems of multiple construction procedures, extended construction period, non-recyclable utilization, etc., and achieve the effect of simple and fast construction operation, stable and safe operation, and saving construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for the construction operation of the present invention on the large-area ultra-soft soil site includes the following steps:

[0045] 1. Clean up the construction site and prepare for construction work.

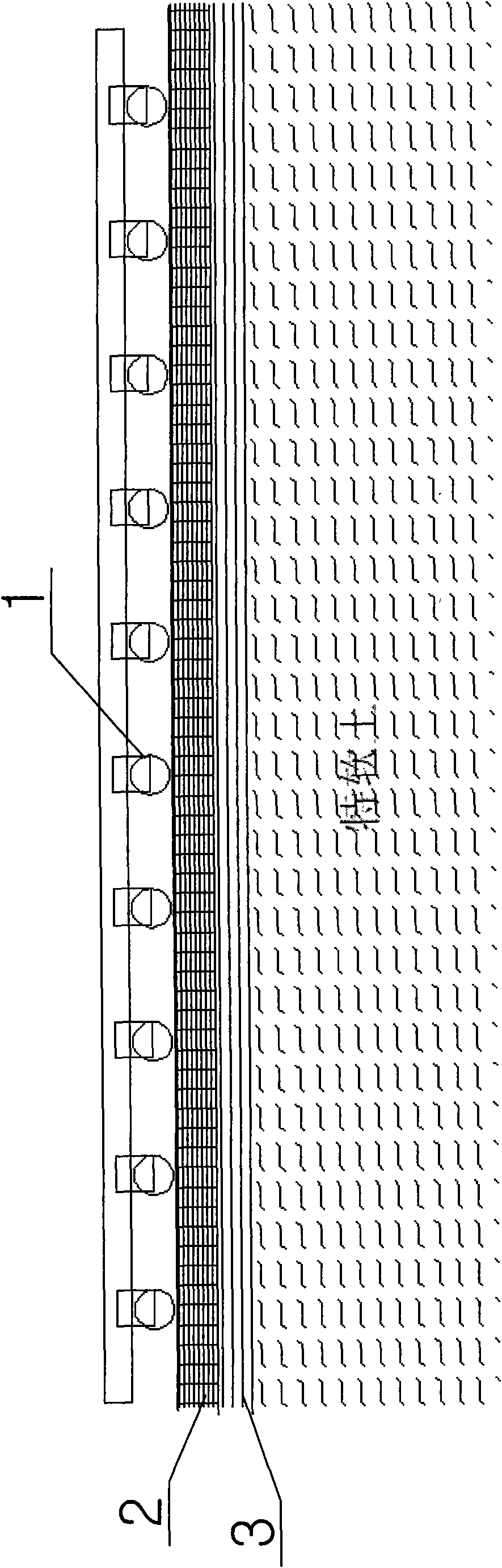

[0046] 2. Lay a layer of geotextile on the construction site, generally woven geotextile is more appropriate.

[0047] 3. Lay a layer of two-way geogrid on the laid geotextile.

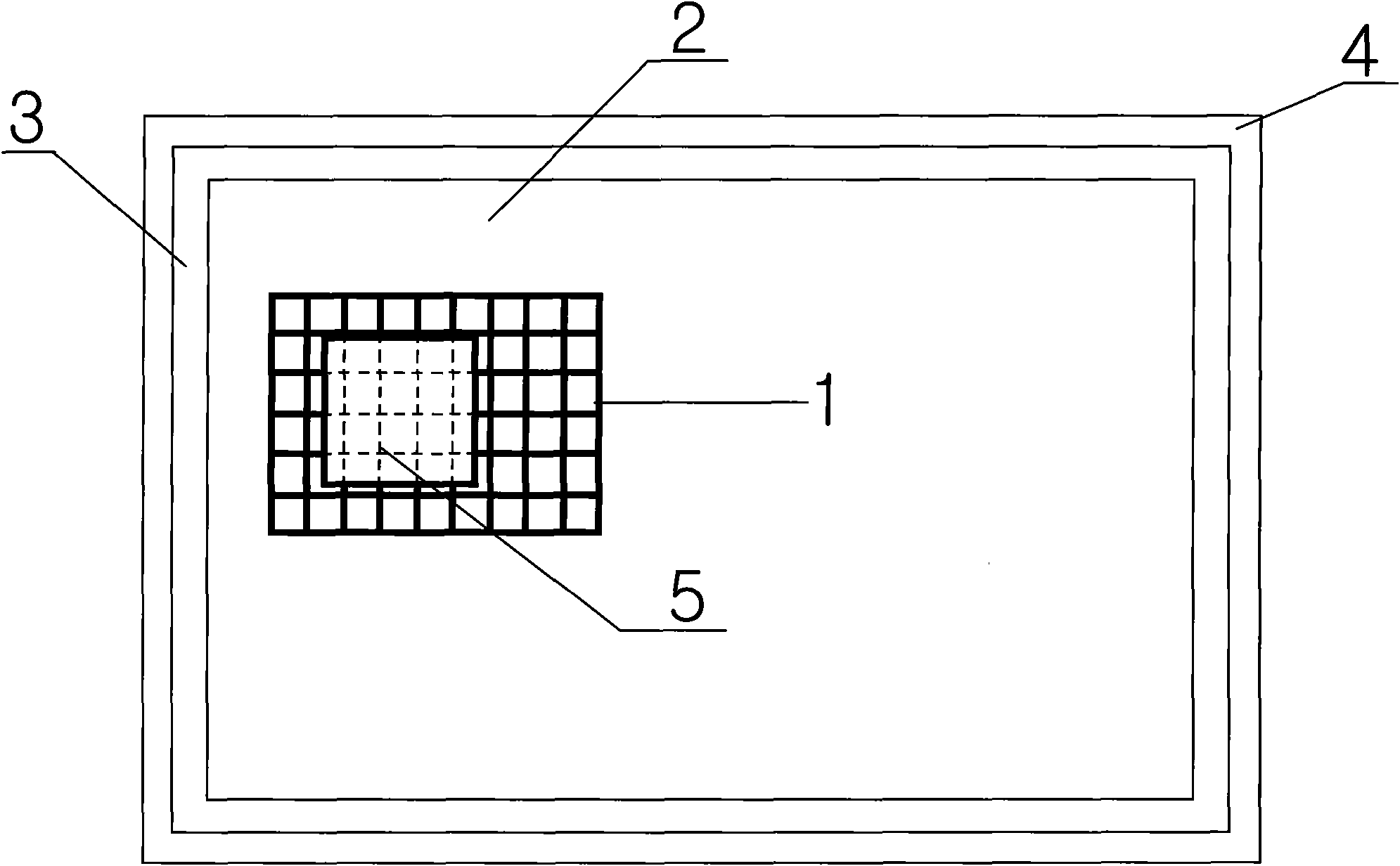

[0048] 4. Lay the steel frame system on the geogrid. If the bearing capacity of the site is sufficient and the subsidence of the lower steel pipe is not large, the following steel frame system 1 can be used, and the steel frame system construction can be carried out according to the following laying method:

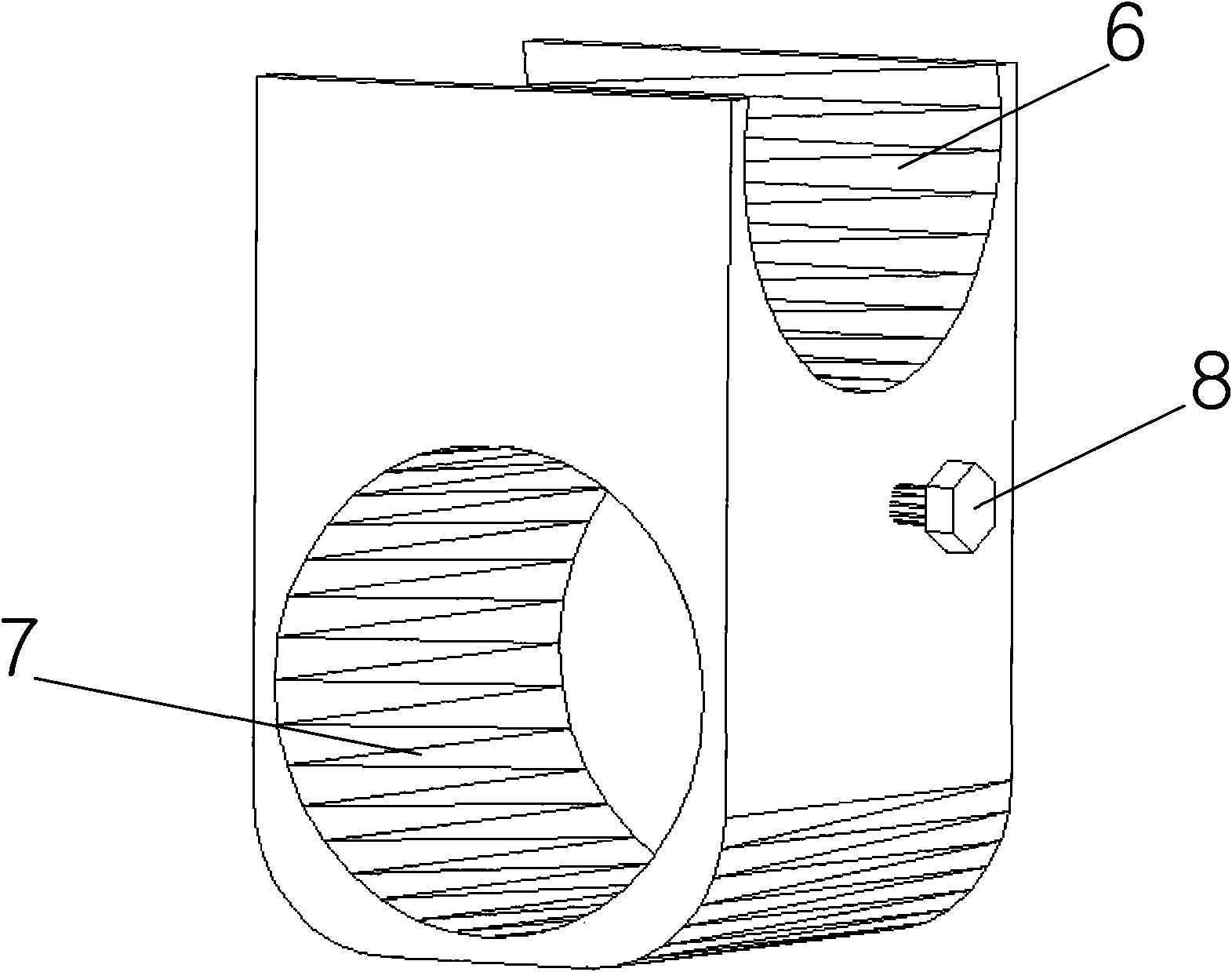

[0049] The steel frame system used in the method of construction operation on a large-area ultra-soft soil site according to the present invention, the steel frame system 1 includes several first bottom steel pipes 9, several horizontal displacement limiting rings 10, several ...

Embodiment 2

[0081] The difference between the present invention and Embodiment 1 is that if the bearing capacity of the site is too low, causing the subsidence of the lower steel pipe to be too large, the following steel frame system 1 should be adopted. The steel frame system 1 includes several positioning steel pipes 13, positioning steel pipes Groove 14, several second bottom steel pipes 15, second bottom steel pipe grooves 16, several second top steel pipes 17, several positioning steel pipes 13 are laid in parallel, but not on a straight line, the positioning steel pipe grooves of positioning steel pipes 13 14 keeps facing upwards, several second bottom steel pipes 15 are laid on the laying direction perpendicular to the positioning steel pipe 13, and the second bottom steel pipe grooves at the two ends of the second bottom steel pipe 15 are facing downward, and snapped into the upper part of the positioning steel pipe 13. Position the steel pipe groove 14; several second top layer st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com