Method for preparing composite protein feed by mixed fermentation

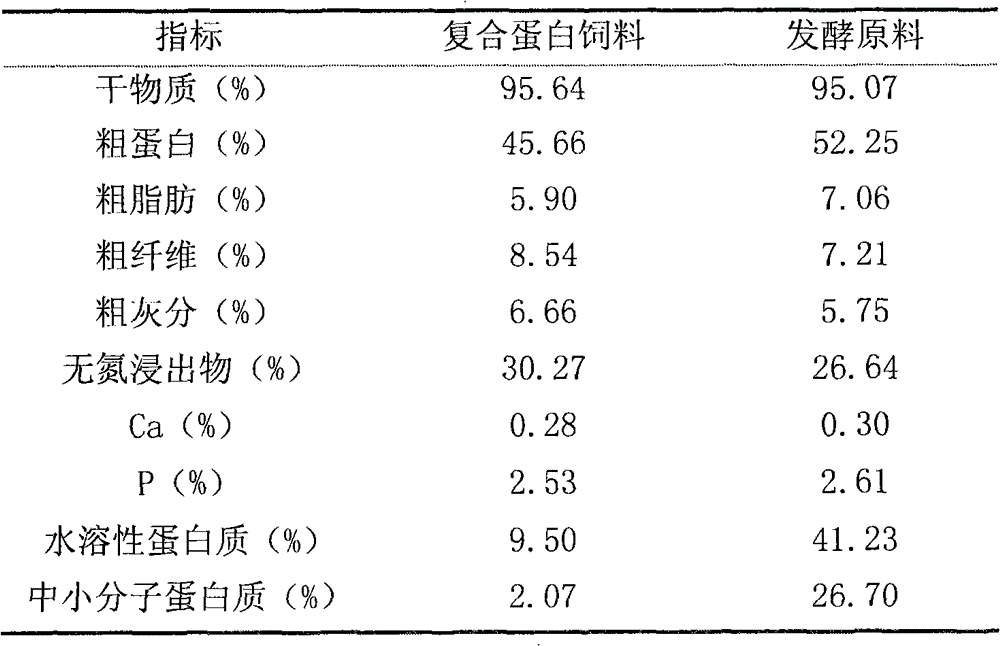

A technology of mixed fermentation and compound protein, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of affecting the palatability of feed, reducing animal feed intake, etc., to reduce the molecular weight of fermented compound feed protein, remove the odor of silkworm pupae, improve the palatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The strains used in this example are 2 strains of Bacillus subtilis, 1 strain of Lactobacillus, and 1 strain of Saccharomyces crevisiae. The specific steps are:

[0030] A. the LB liquid culture medium that is made up of 5 gram peptones, 5 gram yeast extracts, 3 gram sodium chloride and 1 liter of water (pH7.0), pours in the aseptic Erlenmeyer flask, makes Bacillus subtilis seed liquid culture medium and Liquid expansion medium; composed of 2 g tryptone, 5 g NaCl, 2 g glucose, 3 g KH 2 PO 4 , 3 grams K 2 HPO 4 , 0.2 g MgCl 2 , 0.05 g CaSO 4, 2 grams of starch and 1 liter of water (pH6.5) to form a lactic acid bacteria medium, pour it into a sterile triangular flask to make a lactic acid bacteria seed liquid medium and a liquid expansion medium; 100 grams of malt extract powder, 0.1 gram of chlorine Mycin and 1 liter of water (pH6.0) composed of wort culture medium, poured into a sterile Erlenmeyer flask to make yeast seed liquid culture medium and liquid expansion...

Embodiment 2

[0056] The difference from Example 1 is:

[0057] c. Inoculate the seed liquid with an inoculum size of 5% of the total weight of the medium by weight in the liquid expansion LB medium (Bacillus subtilis) and wort medium (brewer's yeast), respectively, and the Bacillus subtilis at a temperature of 37°C , 170rpm, shaker for 20 hours. Saccharomyces cerevisiae was cultured at 30° C., 170 rpm, and a shaking table for 28 hours. Inoculate the lactic acid bacteria seed solution with a weight of 5% of the total weight of the medium in the liquid expanded lactic acid bacteria culture medium (lactic acid bacteria), and inoculate the lactic acid bacteria seed liquid at a temperature of 35° C. for 48 hours. The strain fermentation culture liquid of Bacillus subtilis, brewer's yeast and lactic acid bacteria is uniformly mixed in a ratio of 1:2:2, and used as a strain liquid for fermentation of soybean meal, peanut cake and silkworm chrysalis mixed raw materials.

[0058] d. Weigh the soy...

Embodiment 3

[0062] The difference from Example 1 is:

[0063] c. Inoculate the seed liquid with an inoculum size of 5% of the total weight of the medium by weight in the liquid expansion LB medium (Bacillus subtilis) and wort medium (brewer's yeast), respectively, and the Bacillus subtilis at a temperature of 37°C , 170rpm, shaker for 20 hours. Saccharomyces cerevisiae was cultured at 30° C., 170 rpm, and a shaking table for 28 hours. Inoculate the lactic acid bacteria seed solution with a weight of 5% of the total weight of the medium in the liquid expanded lactic acid bacteria culture medium (lactic acid bacteria), and inoculate the lactic acid bacteria seed liquid at a temperature of 35° C. for 48 hours. The strain fermentation culture liquid of Bacillus subtilis, brewer's yeast and lactic acid bacteria is uniformly mixed according to the ratio of 1:1:1, and used as the strain liquid for fermentation of soybean meal, peanut cake and silkworm chrysalis mixed raw material.

[0064] d. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com