Method and device for microwave continuous heating sterilization of solid materials

A technology of heat sterilization and microwave heating, which is applied in food science, food preservation, application, etc., and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

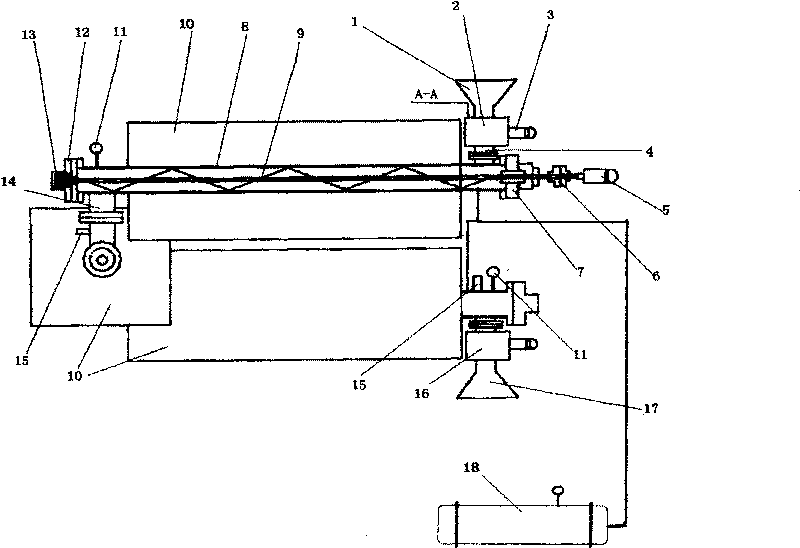

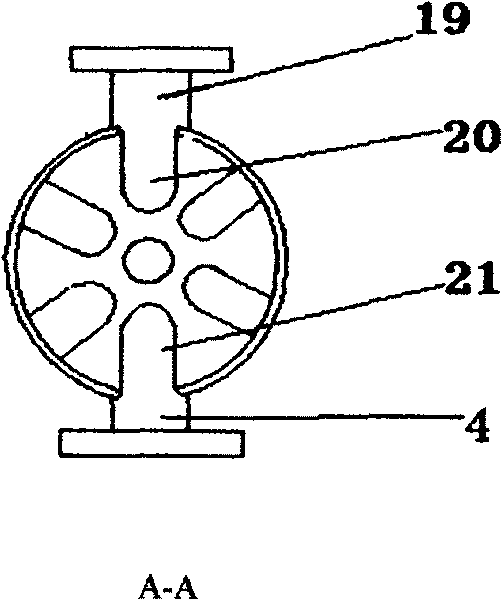

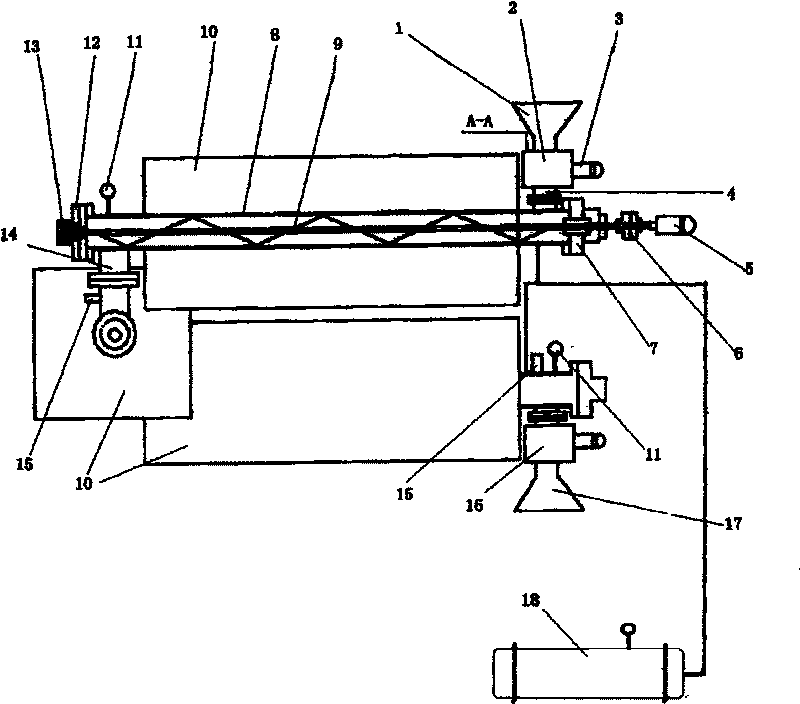

[0024] The device for microwave continuous heating and sterilization of solid materials is composed of multiple single-stage devices and steam generators (18), wherein the single-stage device for microwave continuous sterilization of solid materials consists of a feed inlet (1), a cock type continuous feed Material sealing valve (2), tubular screw propeller (8), microwave heating chamber (10), discharge port (14), cock type continuous discharging sealing valve (16), temperature sensor (15), pressure sensor ( 11) Composition; the pressure and temperature sensors are installed at the connection between the stages of the microwave heating outdoor tubular screw propeller.

[0025] The feed port and discharge port of the cock type continuous feed and discharge sealing valve (2) are not connected to each other when they are opened, and can simultaneously complete the continuous feed and discharge of solid materials while maintaining the effective working air pressure in the device. ...

Embodiment 2

[0029] The special device for microwave continuous heating and sterilization of solid materials is composed of multiple single-stage devices and steam generators, which are the same as the above-mentioned embodiments, wherein the microwave heating chamber can be used in series by multiple low-power resonant cavities. The specific microwave heating Chamber design is determined by relevant process parameters. In addition, the heating chamber must be able to work continuously for a long time, and its power can be accurately adjusted online.

Embodiment 3

[0031]After the solid material to be sterilized is preheated with hot air, it is continuously fed into the screw propeller (8) from the feed port (1) through the cock type continuous feeding sealing valve (2), and is stirred along the long axis of the screw propeller And pushed forward, the material is heated according to the process requirements when passing through the microwave heating chamber (10). Heating the stage-to-stage junctions of outdoor tubular auger propellers. The material is conveyed from the previous stage to the next stage by the screw propeller, and the material is further heated to the sterilization temperature by the microwave in the next stage. The temperature and ambient pressure of the material at this stage are also monitored and controlled online by the temperature sensor and the pressure sensor between the stages. The material is further conveyed to the next stage by the screw propeller. In this stage, the microwave heating power is reduced, mainly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com