Method for preparing streptavidin pre-coated elisa plate and application

A streptavidin and pre-coating technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of cumbersome process, unstable streptavidin fixation, and no streptavidin yet. The preparation method is simple, suitable for long-term storage, and the effect of coating is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

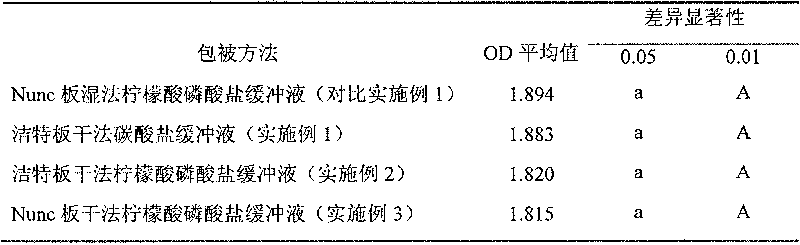

Embodiment 1

[0026] The blank microtiter plate is Jiete high affinity microtiter plate.

[0027] Use pH 9.6, 0.05M carbonate buffer (1.59g sodium carbonate and 2.93g sodium bicarbonate diluted with water to 1000mL) to dilute streptavidin to 2 μg / ml to obtain coating buffer; Add it to a blank microtiter plate, 100 μl per well, and then incubate overnight at 37°C in an incubator until completely dry to obtain a streptavidin pre-coated microtiter plate. The dried microtiter plates should be packed in sealed bags and stored at 4°C.

Embodiment 2

[0029] The blank microtiter plate is Jiete high affinity microtiter plate.

[0030] Use pH 5.0, 0.15M citrate phosphate buffer (1030ml 0.1M citric acid and 970ml 0.2M Na 2 HPO 4 Mix to obtain) dilute streptavidin to 2 μg / ml to obtain coating buffer; add coating buffer to a blank microplate plate, 100 μl per well, and then incubate overnight at 37°C in an incubator until complete Dry to obtain a streptavidin pre-coated microtiter plate. The dried microtiter plates should be packed in sealed bags and stored at 4°C.

Embodiment 3

[0032] Blank microtiter plate is Nunc microtiter plate.

[0033] Use pH 5.0, 0.15M citrate phosphate buffer (1030ml 0.1M citric acid and 970ml 0.2M Na 2 HPO 4 Mix to obtain) dilute streptavidin to 2 μg / ml to obtain coating buffer; add coating buffer to a blank microplate plate, 100 μl per well, and then incubate overnight at 37°C in an incubator until complete Dry to obtain a streptavidin pre-coated microtiter plate. The dried microtiter plates should be packed in sealed bags and stored at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com