Lithium ion secondary battery

A secondary battery and lithium ion technology, applied in the direction of secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of battery performance degradation such as cycle characteristics, shortened electrode life, battery deformation, etc., to achieve excellent output characteristics and durable life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] (1) Preparation of positive electrode active material

[0167] in NiSO 4 In the aqueous solution, cobalt sulfate was added according to the amount of Ni:Co=8.5:1.5 (molar ratio) to prepare an aqueous solution with a metal ion concentration of 2 mol / L. Slowly add 2mol / L sodium hydroxide solution dropwise to the aqueous solution under stirring to neutralize, thereby forming a Ni 0.85 co 0.15 (OH) 2 Indicates the composition of the ternary precipitate. The precipitate was separated by filtration, washed with water, and dried at 80°C to obtain a composite hydroxide.

[0168] Heat the composite hydroxide at 900°C for 10 hours in the atmosphere to obtain 0.85 co 0.15 A composite oxide with a composition represented by O. Lithium hydroxide monohydrate was added so that the sum of the atomic numbers of Ni and Co was equal to the atomic number of Li, and heated at 800°C for 10 hours in the atmosphere for heat treatment, so as to obtain LiNi 0.85 co 0.15 o 2 The composi...

Embodiment 2

[0192] A lithium ion secondary battery of the present invention was produced in the same manner as in Example 1 except that the production method of the negative electrode was changed as follows.

[0193] [Production of Negative Electrode]

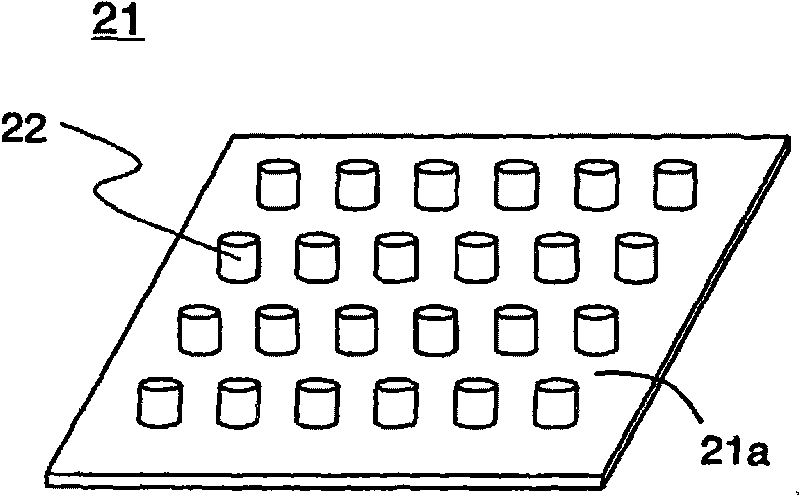

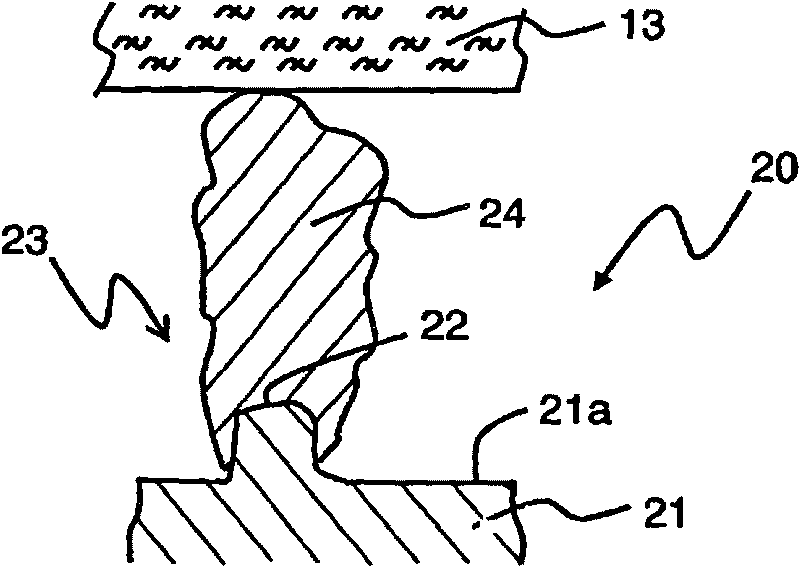

[0194] Chromium oxide was sprayed on the surface of an iron roll with a diameter of 50 mm to form a ceramic layer with a thickness of 100 μm. On the surface of this ceramic layer, a circular concave portion, namely a hole, having a diameter of 12 μm and a depth of 8 μm was formed by laser processing to produce a roller for convex portion. The arrangement of the holes was set to be a close-packed arrangement in which the distance between the axes of a pair of adjacent holes was 20 μm. The central portion of the bottom of the hole is substantially planar, and the portion where the end of the bottom is connected to the side surface of the hole is rounded.

[0195] An alloy copper foil (trade name: HCL-02Z, 20 μm thick, manufactured by Hitac...

Embodiment 3

[0207] Except that no supporting salt (LiPF 6 ) except that the lithium ion secondary battery of the present invention was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com