Active clamping forward-flyback converter

A flyback converter and clamping technology, applied in the field of converters, can solve the problems of power range, input and output voltage variation range limitations, restrictions, etc., to improve efficiency, reduce voltage stress, and reduce reverse steady-state voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

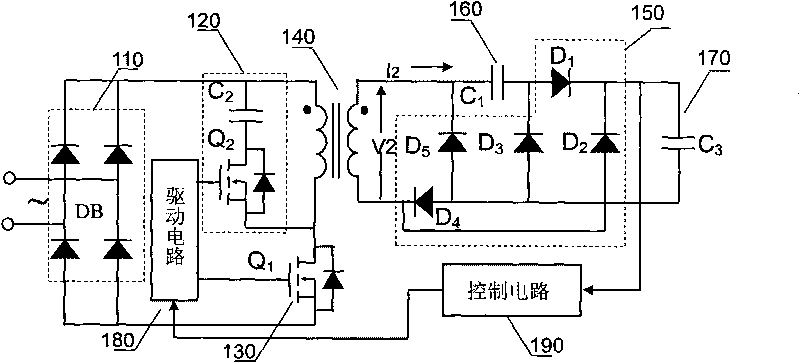

[0036] a kind of like Figure 1~6 The shown active clamp forward-flyback converter includes an input circuit 110, a switch tube drive circuit 180, an inverter switch tube 130, an isolation transformer 140, a primary side clamp resonant circuit 120, a secondary rectifier circuit 150, a secondary A staged direct voltage dividing capacitor 160 , an output filter capacitor 170 , and a voltage control circuit 190 .

[0037] The input circuit 110 is used to rectify the alternating voltage. Because it is not connected to a large-capacity input filter capacitor, it can better follow the input voltage to ensure the power factor (Power Factor, referred to as PF) and total harmonic content (Total Harmonics Distortion, referred to as THD) of the input power supply

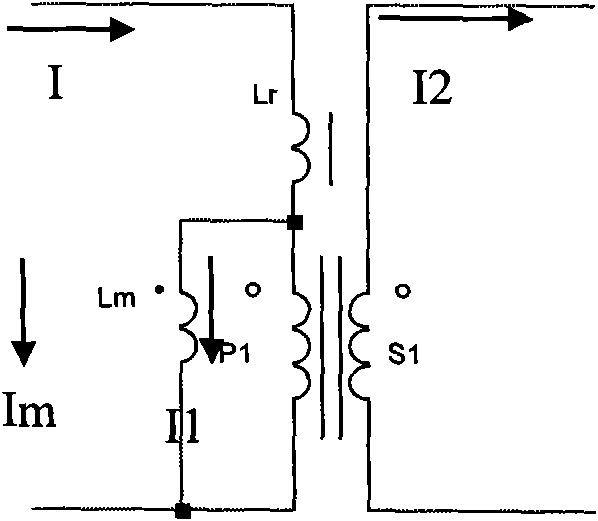

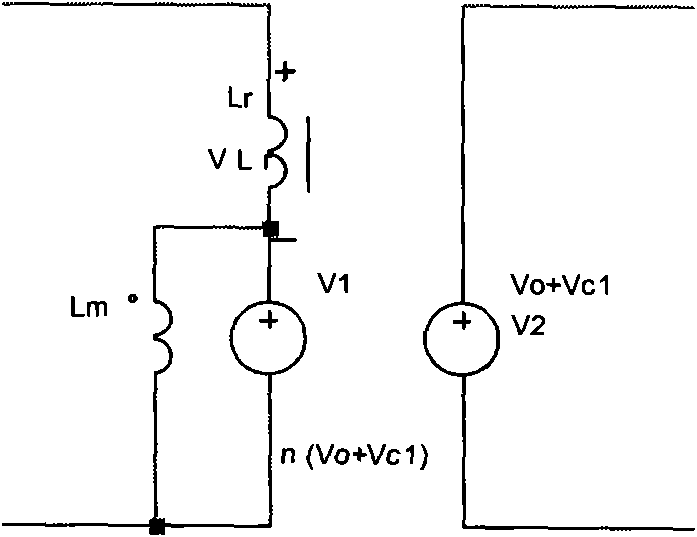

[0038] The inverter circuit is composed of an inverter switch tube Q1 and an isolation transformer 140 , and the primary-side clamp resonant circuit 120 is composed of a clamp capacitor C2 , a clamp switch tube Q2 and a trans...

specific Embodiment approach 2

[0069] a kind of like Figure 7 The shown active clamp forward-flyback converter has the same basic circuit composition and beneficial effects as the specific embodiment 1, the difference is: the series branch composed of the clamp switch tube and the primary side clamp capacitor is connected in series to the isolated Between the beginning of the primary winding on the primary side of the transformer and the negative terminal of the DC power supply, rather than in parallel with the primary winding on the primary side of the isolation transformer.

specific Embodiment approach 3

[0070] a kind of like Figure 8 The shown active clamp forward-flyback converter has the same basic circuit composition and beneficial effects as the first embodiment, the difference is that the secondary winding of the isolation transformer 140 has an additional winding L0 extending outwards at its starting end. secondary windings, rather than separate secondary windings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com