Process for degumming and pre-cleaning silicon slices

A pre-cleaning, silicon wafer technology, applied in the direction of using liquid cleaning methods, detergent compositions, cleaning methods and utensils, etc. Quality, not easy to dry, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

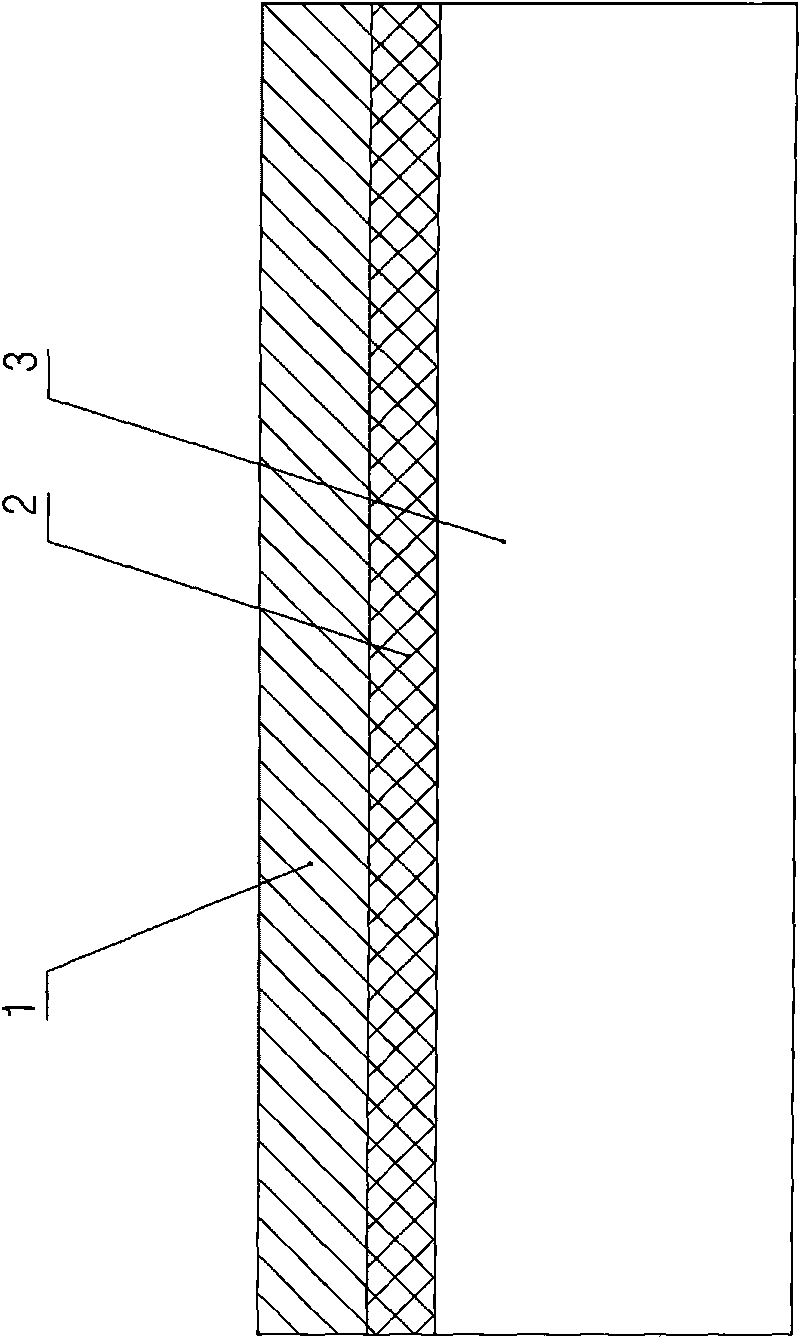

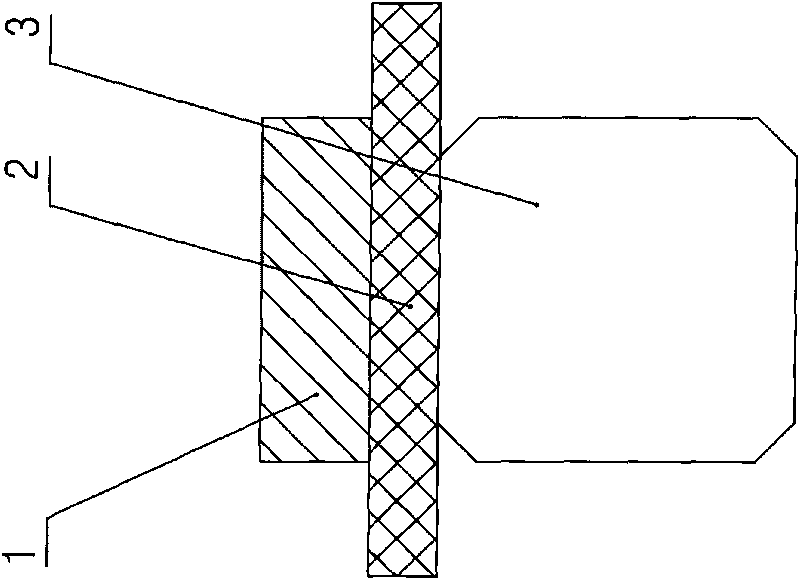

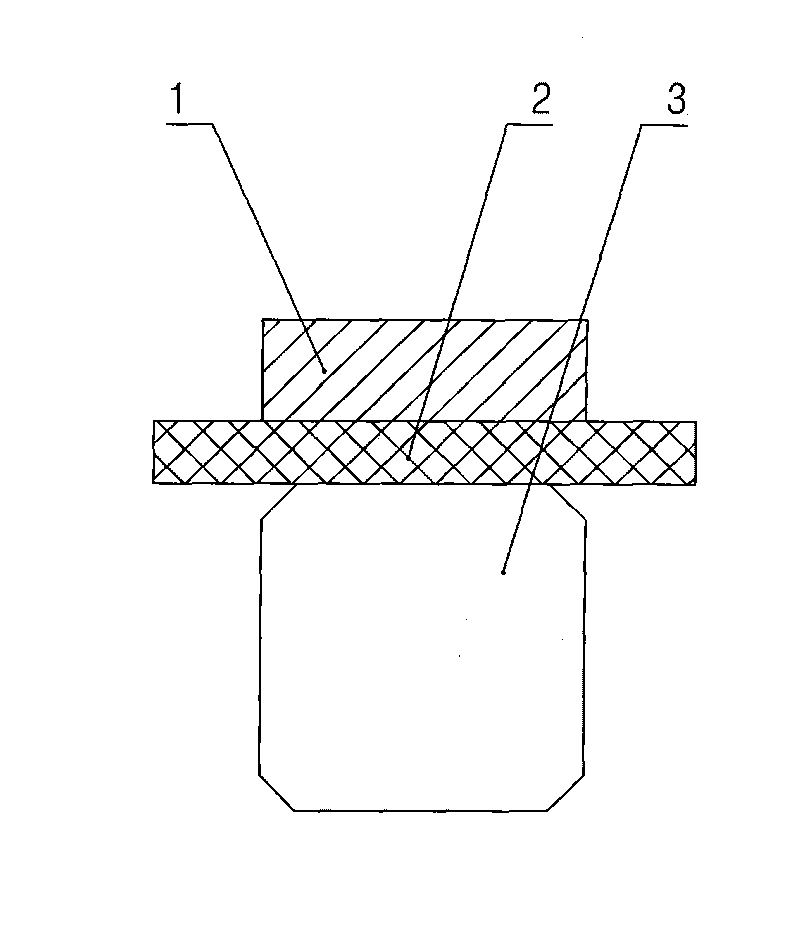

Image

Examples

Embodiment 1

[0012] After the silicon rods are cut into silicon wafers, the silicon wafers are glued with AB glue for bonding. Put the silicon wafers with the AB glue in the silicon rod cutting fluid, heat to 70°C, and add a liter of silicon rod cutting Ultrasonic wave with a power density of 8 watts, after 5 minutes of cleaning, removes the AB glue on the silicon wafer.

Embodiment 2

[0014] After the silicon rods are cut into silicon wafers, the silicon wafers are glued with AB glue for bonding, and the silicon wafers with the AB glue are placed in the silicon rod cutting fluid, heated to 80°C, and mixed with a liter of silicon rod cutting fluid Ultrasonic with a power density of 6.5 watts, after 4 minutes of cleaning, removes the AB glue on the silicon wafer.

Embodiment 3

[0016] After the silicon rods are cut into silicon wafers, the silicon wafers are glued with AB glue for bonding, and the silicon wafers with the AB glue are placed in the silicon rod cutting fluid, heated to 90°C, and mixed with a liter of silicon rod cutting fluid Ultrasound with a power density of 5 watts, after 3 minutes of cleaning, removes the AB glue on the silicon wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com