Warm white light light-emitting diode (LED) and lithium matter fluorescent powder thereof

A light-emitting diode, warm white light technology, applied in the directions of luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of uneven luminous brightness and luminous color of light-emitting diodes, a large amount of blue light radiation, lack of covering layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

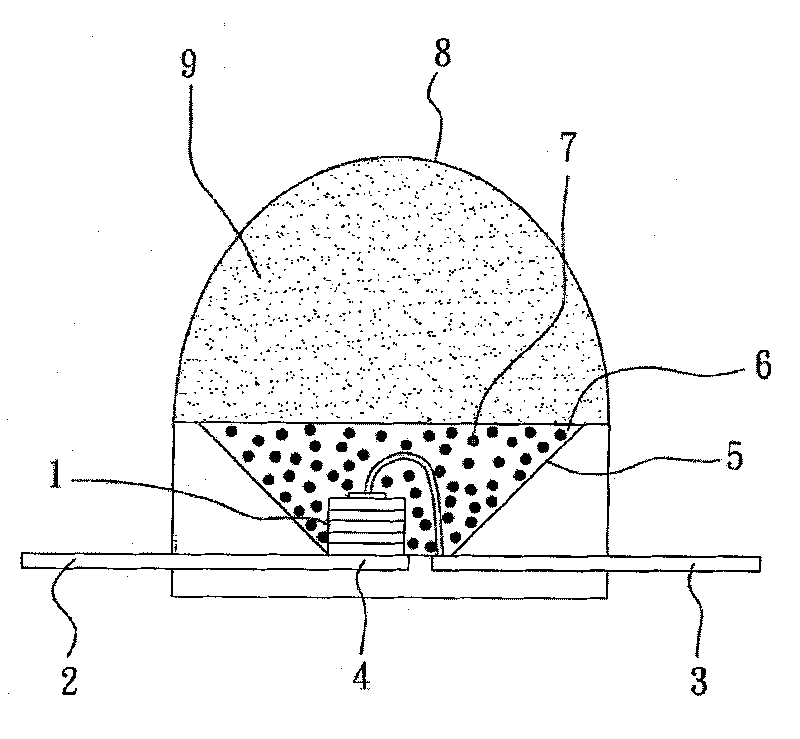

[0035] First of all, the object of the present invention is to eliminate the above-mentioned disadvantages of warm white light-emitting diodes. In order to achieve this goal, the warm white light emitting diode of the present invention has a structure similar to figure 1 The structure described in , so it will not be further illustrated here, is based on an indium gallium nitride heterojunction, and its composition contains a large number of quantum wells. It has a polymerized light-emitting conversion layer, which is characterized in that: the polymerized The luminescence conversion layer exists in the form of uniform concentration. The luminescent surface and edge of the indium gallium nitride heterojunction are covered with a thermosetting polymer layer, and the polymerized luminescence conversion layer contains a number of phosphor particles. These particles are composed of at least two layers. The particle layer exists in the polymerized light-emitting conversion layer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com