Microalgae culture method and photo-bioreactor system thereof

A technology for photobioreactor and microalgae cultivation, applied in the field of new photobioreactor system, can solve the problems of many reactors, complicated liquid and liquid transportation, no supplementary light system, etc., achieve rapid biomass accumulation, prevent light intensity Insufficient, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

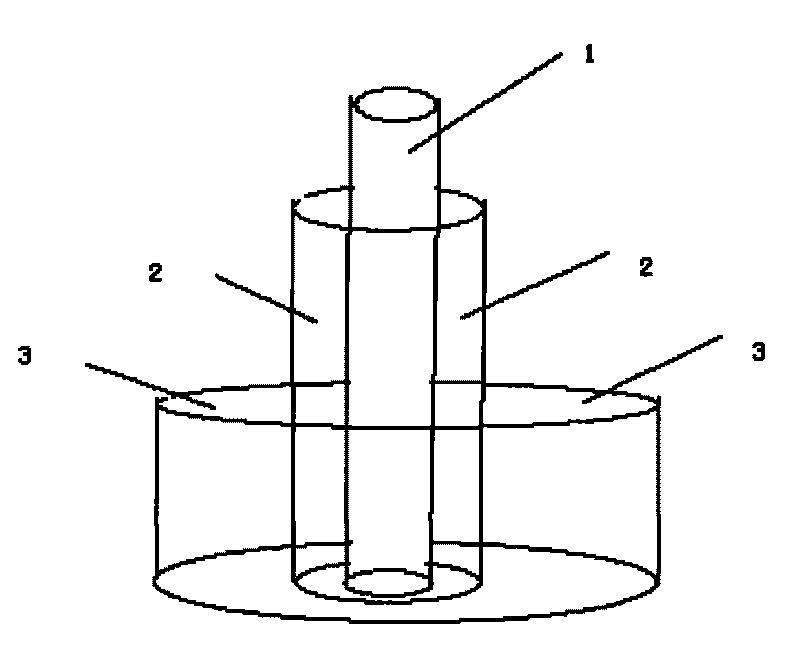

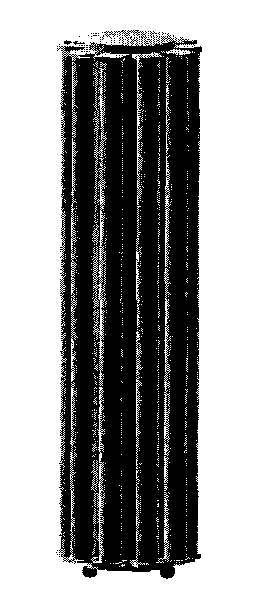

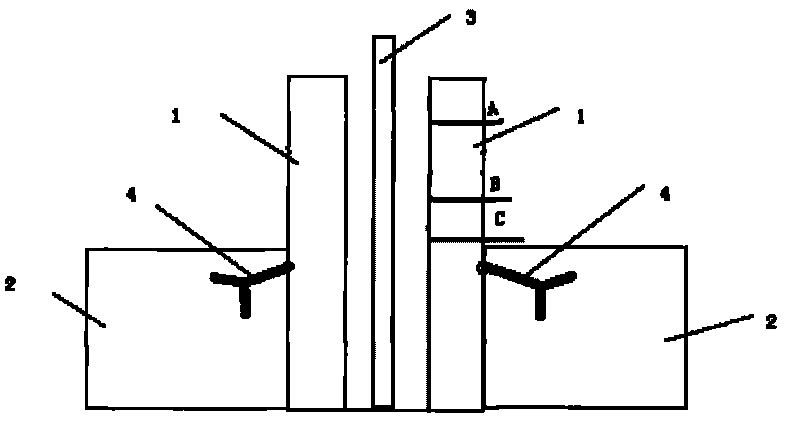

Method used

Image

Examples

Embodiment 1 3

[0049] Example 1 The three-step culture method and the application of nitrogen stress in the culture of Chaetoceros Mounerii.

[0050] The formula of the culture solution used in the present invention:

[0051] Improved f / 2 medium formula:

[0052] Nutrients

Concentration (mg / L)

NaNO 3

37.5

15

Na 2 SiO 3 .9H 2 O

30

NaH 2 PO 4 .2H 2 O

5.66

[0053] Nutrients

Concentration (mg / L)

Na 2 HPO 4

5.15

FeCl 3 .6H 2 O

3.162

Na 2 .EDTA

3.419

CuSO 4 .5H 2 O

0.01

ZnSO 4 .7H 2 O

0.023

CoCL 2 .6H 2 O

0.012

MnCL 2 .4H 2 O

0.18

Na 2 MoO 4 .2H 2 O

0.07

VB1

0.1

VB12

0.5×10 -3

0.5×10 -3

MgCl 2 .7H 2 O

7.5

Sea crystal (is a substance commonly used to simulate sea water, purchase

From Tianjin Zhongyan Marine Biological Science Co., Ltd.

30

[0054] Formula of Nitrogen Deficiency Culture Solution: NaH 2 PO 4 .2H 2 O 5.66mg / L, Na 2 HPO 4 5.15mg / L, FeCl 3 .6H 2 O 3.162mg / L, Na 2 .EDTA 3.419mg / L, sea crystal is 30mg / ...

Embodiment 2 3

[0064] Example 2 Application of the three-step culture method and nitrogen stress in the culture of Scenedesmus desert.

[0065] Scenedesmus deserticola (Scenedesmus deserticola) was purchased from Jinan University. The Scenedesmus desert was connected to the first-stage reactor, and BG11 medium was used to inoculate the algae liquid in the logarithmic growth phase (the inoculation ratio was 5:1), and the initial OD 750 Is 0.583. Cultivation is conducted under continuous light, the light is the light beam designed by the present invention, the light intensity is 126±10umol / (m2.s), and the culture temperature is 25±5°C. Air and CO are introduced from the bottom of the first-stage reactor through the aeration head 2 Mixed gas, ventilation rate is 2.5L / min, CO 2 The percentage content of 5% is 5%, and the continuous cultivation time is 10 days. See the specific growth situation Figure 7 . In the first-stage reactor, using semi-continuous culture, by monitoring the OD value at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com