Heat insulating material for forging large-size forge piece

A technology for thermal insulation materials and large forgings, which is applied in applications, household appliances, and other household appliances, etc. It can solve the problems of binder loss, damage to the physical and mental health of the operator, and the temperature reduction of forgings, so as to achieve the effect of reducing the heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

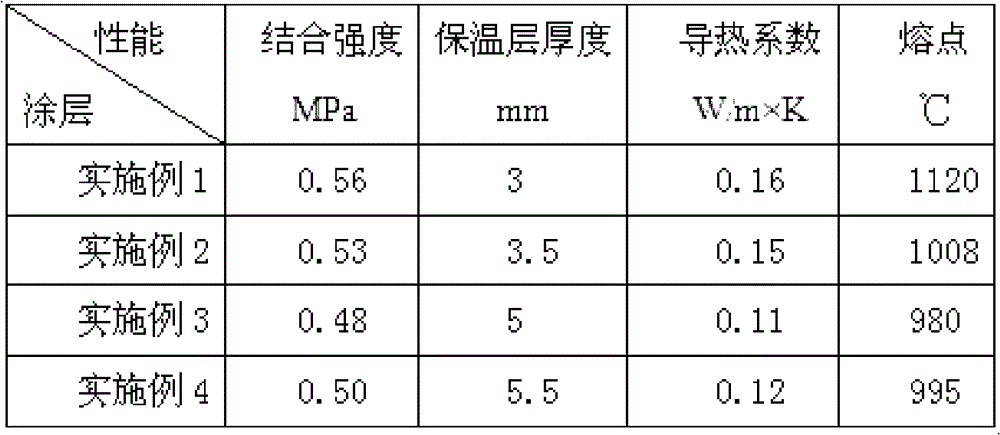

Embodiment 1

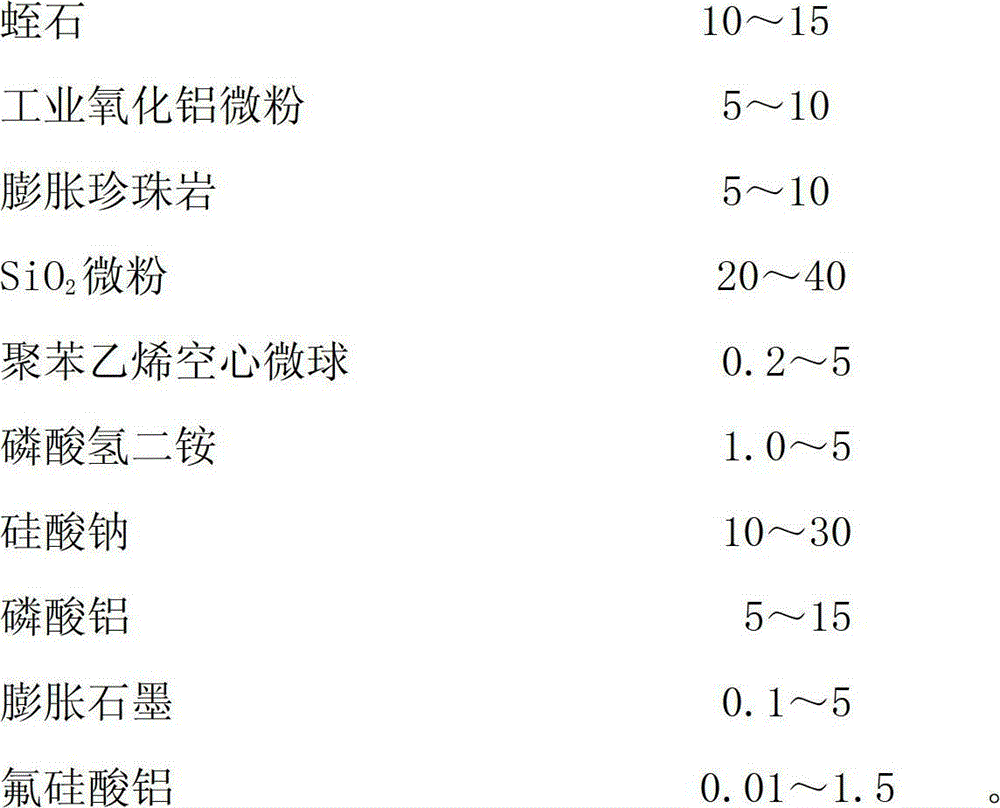

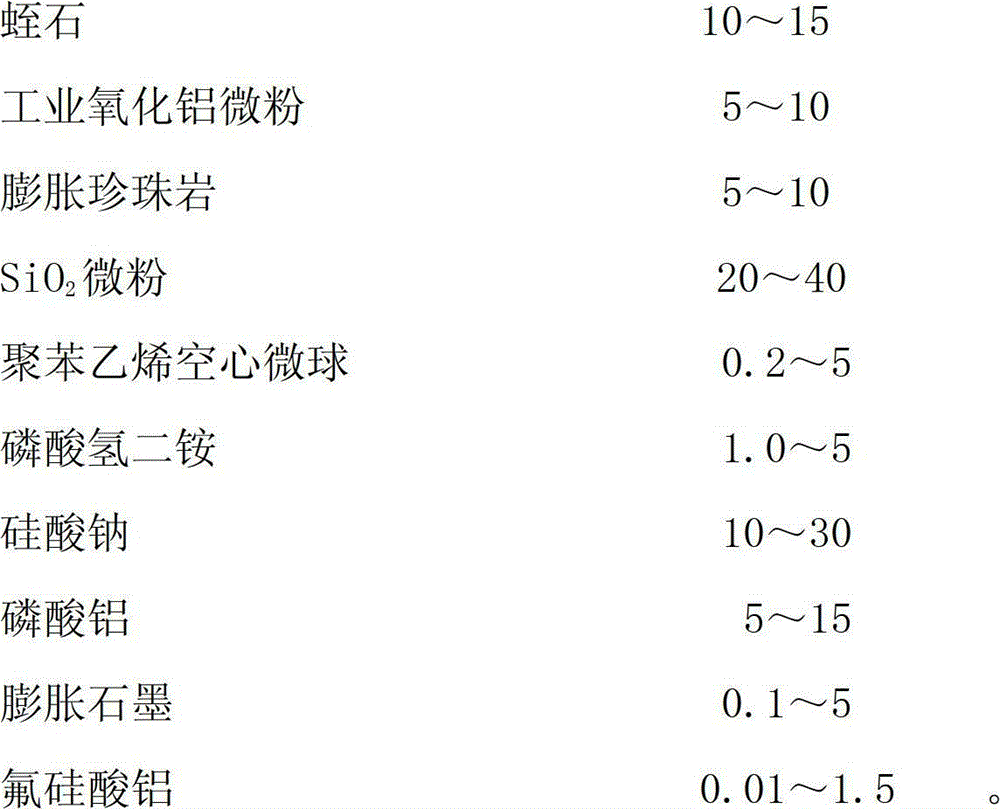

[0033] The type and amount of raw materials (in kilograms):

[0034] Vermiculite 10

[0035] Industrial alumina powder 5

[0036] expanded perlite 5

[0037] SiO 2 Micronized 20

[0038] Polystyrene hollow microspheres 0.2

[0039] Diammonium hydrogen phosphate 1.0

[0041]Aluminum phosphate 5

[0042] Expanded graphite 0.5

[0043] Aluminum fluorosilicate 0.01

[0044] After the above raw materials are baked and dried, they are weighed according to the proportion, and then placed in a V-shaped mixer in order to mix and disperse evenly to obtain the thermal insulation material for forging large forgings.

Embodiment 2

[0046] The type and amount of raw materials (in kilograms):

[0047] Vermiculite 10

[0048] Industrial alumina powder 8

[0049] expanded perlite 5

[0050] SiO 2 Micronized 25

[0051] Polystyrene hollow microspheres 0.5

[0052] Diammonium hydrogen phosphate 3.0

[0054] Aluminum phosphate 5

[0055] Expanded graphite 0.2

[0056] Aluminum fluorosilicate 0.01

[0057] After the above raw materials are baked and dried, they are weighed according to the proportion, and then placed in a V-shaped mixer in order to mix and disperse evenly to obtain the thermal insulation material for forging large forgings.

Embodiment 3

[0059] The type and amount of raw materials (in kilograms):

[0060] Vermiculite 10

[0061] Industrial alumina powder 8

[0062] expanded perlite 5

[0063] SiO 2 Micronized 30

[0064] Polystyrene hollow microspheres 0.3

[0065] Diammonium hydrogen phosphate 3.0

[0067] Aluminum phosphate 5

[0068] Expanded graphite 3

[0069] Aluminum fluorosilicate 0.01

[0070] After the above raw materials are baked and dried, they are weighed according to the proportion, and then placed in a V-shaped mixer in order to mix and disperse evenly to obtain the thermal insulation material for forging large forgings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com