Electrolytic cell in electro-deoxidization metallurgy process

A technology of electro-deoxidation metallurgy and electrolyzer, applied in the direction of electrolysis process, electrolysis components, diaphragm, etc., can solve the problems of large proportion of side reactions, low product quality, low current efficiency, etc., achieve short production cycle, large production capacity, The effect of preventing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

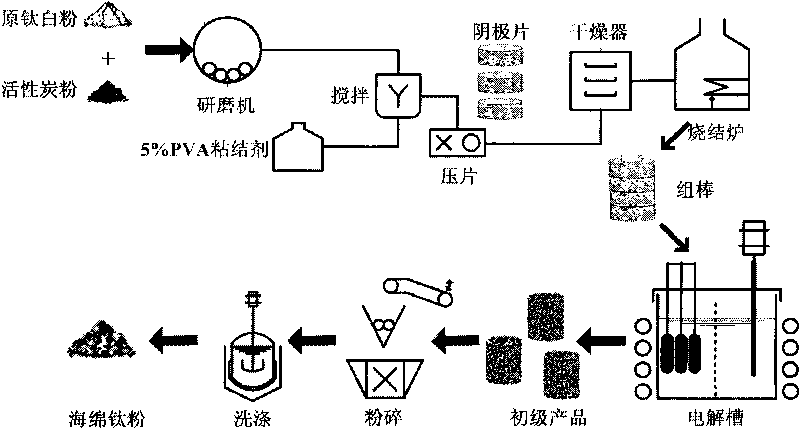

[0019] The cathode of the electrolytic cell adopts titanium oxide cathode rod, which is formed by mixing and sintering titanium dioxide fine powder and PVA binder in proportion. The oxide mass of each cathode rod is about 100g. Group. In the anode area, three rotating graphite anodes are connected in parallel in a manner corresponding to the cathode as electrolysis anodes. The distance between the cathode and the anode is 200mm, and the anode rod speed is set at 120rpm. Remove partitions. Using CaCl 2 molten salt, molten salt CaCl 2 The depth is 140mm, the temperature is controlled at 950°C, the flow rate of protective gas argon is set at 5L / min, the voltage of the electrolytic cell is 3.1V, and the electrolysis time is 36h. For the overall electrolysis process, see image 3 .

[0020] The shape of the product is basically unchanged, the density is high, the color is gray-black, and there is gray layering in the center part. After testing, it is mainly intermediate produc...

example 2

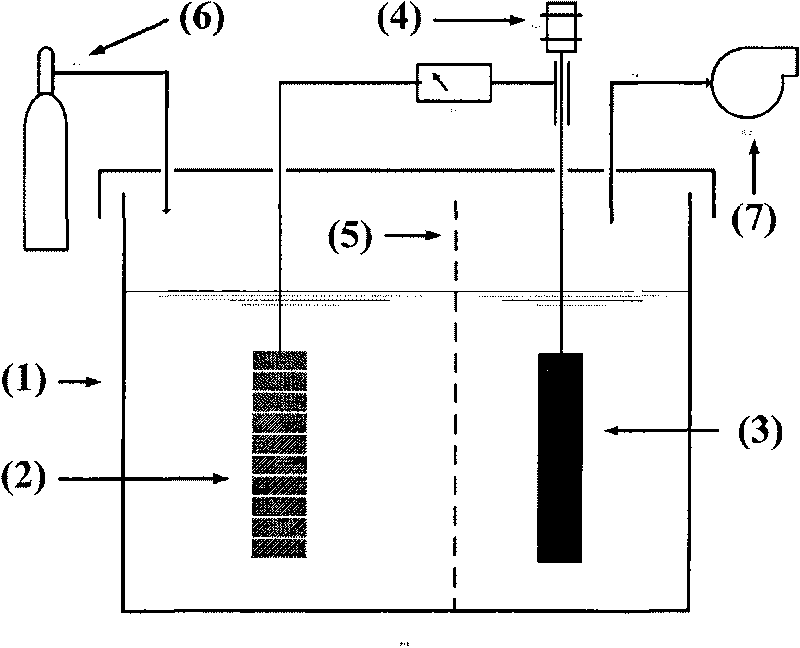

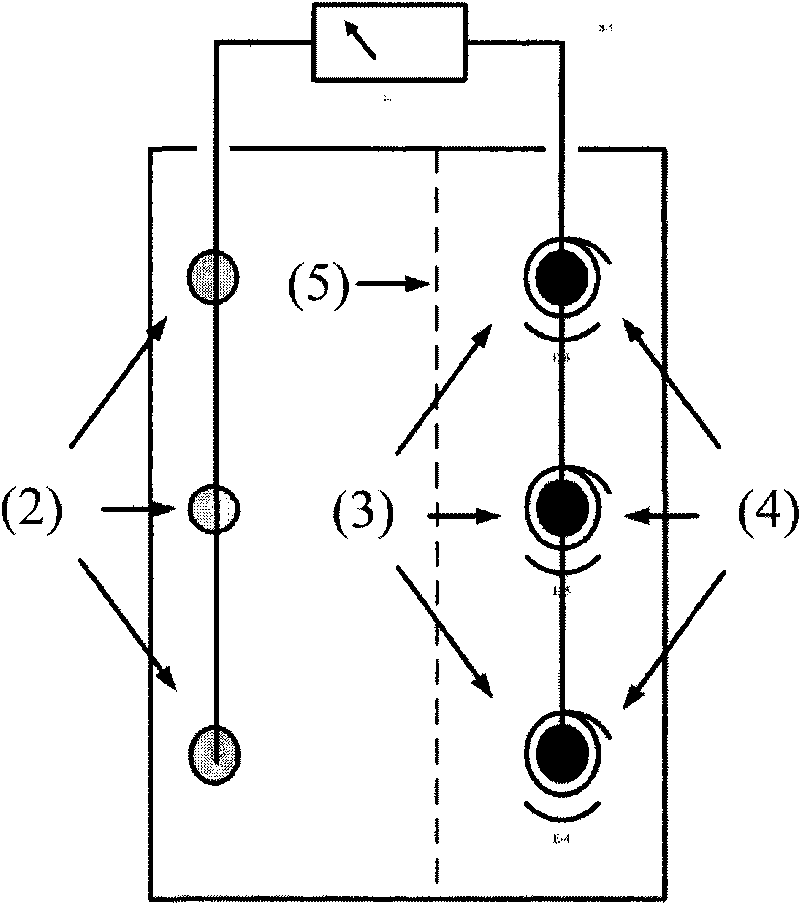

[0022] The cathode of the electrolytic cell adopts titanium oxide cathode rod, which is formed by mixing and sintering titanium dioxide fine powder and PVA binder in proportion. The oxide mass of each cathode rod is about 100g. Group. In the anode area, three rotating graphite anodes are connected in parallel in a manner corresponding to the cathode as electrolysis anodes. The distance between the cathode and the anode is 200mm, and the anode rod speed is set at 180rpm. The separator is made of Al 2 o 3 The material has a porosity of 55%, an apparent porosity of 30%, a thickness of 2mm, and a height of 300mm. The overall configuration of the electrolytic cell is as follows: figure 1 with figure 2 shown. CaCl is used in the electrolytic cell 2 molten salt, molten salt CaCl 2 The depth is 140mm, the temperature is controlled at 950°C, the flow rate of protective gas argon is set at 5L / min, the voltage of the electrolytic cell is 3.1V, and the electrolysis time is 36h. F...

example 3

[0025] The cathode of the electrolytic cell adopts titanium oxide cathode rod, which is formed by mixing and sintering titanium dioxide fine powder and PVA binder in proportion. The oxide mass of each cathode rod is about 100g. Group. In the anode area, three rotating graphite anodes are connected in parallel in a manner corresponding to the cathode as electrolytic anodes. The distance between the cathode and the anode is 200mm, and the anode rod speed is set at 120rpm. The separator is made of MgO material, the porosity is 50%, the apparent porosity is 15%, the thickness is 5mm, and the height is 300mm. The overall configuration of the electrolytic cell is as follows: figure 1 with figure 2 shown. CaCl is used in the electrolytic cell 2 molten salt, molten salt CaCl 2 The control depth is 140mm, the temperature is controlled at 950°C, the protective gas argon flow rate is set at 5L / min, the voltage of the electrolytic cell is 3.1V, and the electrolysis time is 28h. For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com