Device for carrying out optical non-destructive testing on surface of annular inner wall

A non-destructive testing, circular technology, applied in the direction of measuring devices, material analysis through optical means, scientific instruments, etc., can solve the problems of out-of-focus, large field of view and high sensitivity at the same time, and the sensitivity of digital shearing speckle interference technology and the resolution can not be further improved to achieve the effect of eliminating defocusing phenomenon, increasing the area and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

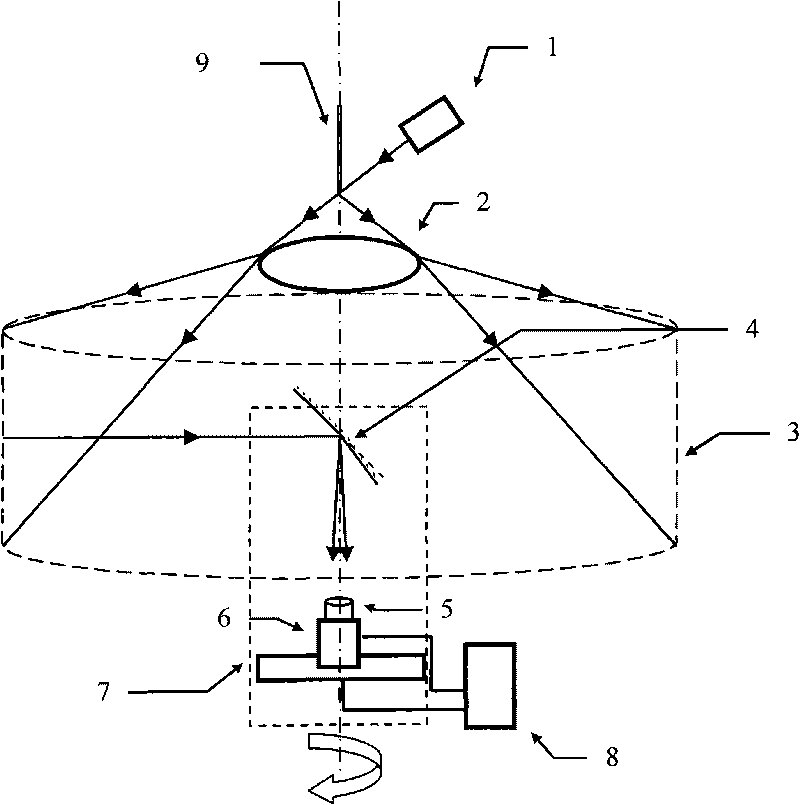

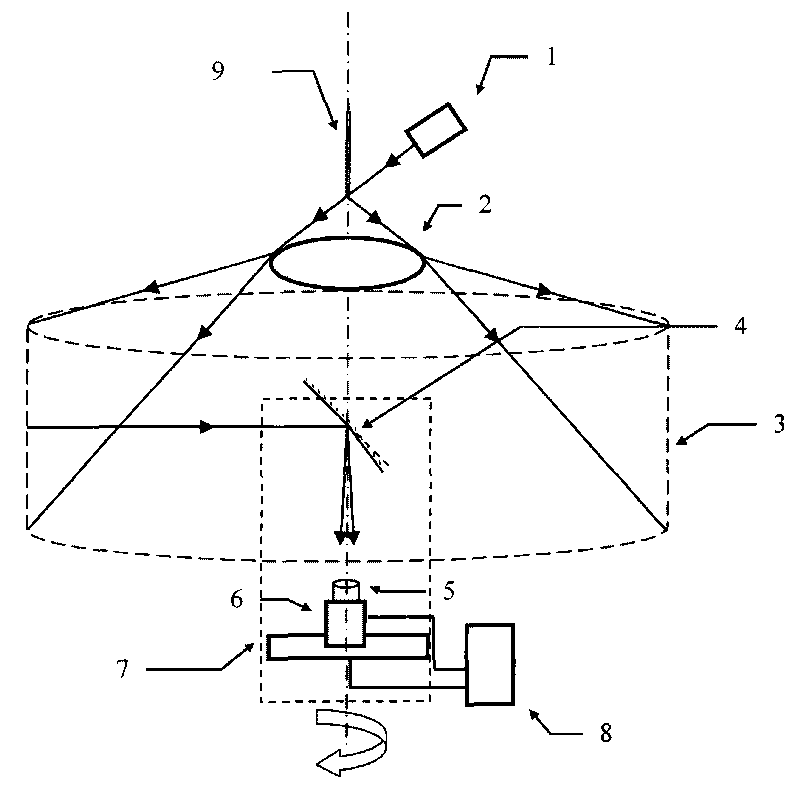

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0030] This embodiment includes a laser 1 , a beam expander 2 , a shearing element 4 , an imaging device 5 , a linear array CCD 6 , a rotary table 7 , a computer 8 and a thin glass rod 9 .

[0031] In the present embodiment, the laser adopts a helium-neon laser; the annular inner wall of an object to be tested 3 is the tire inner wall; the diameter of the thin glass rod 9 is 8mm, which is arranged at a position where the axis of the tire is less than 90mm from the center of the tire, and is parallel to The thin glass rod placed on the axis of the tire can also be replaced by an optical fiber; the laser 1 is located on one side of the thin glass rod, and the thin beam emitted by the laser forms an angle of 1° to 90° with the axis of the glass rod, and the light beam irradiates the end of the glass rod near the tire. The beam expander 2 adopts a bracelet-shaped ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com