Method for preparing natural pork or beef bone flavor essence

A production method and technology of beef bone meat, applied in food preparation, application, food science, etc., to achieve the effect of rich and mellow meat flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

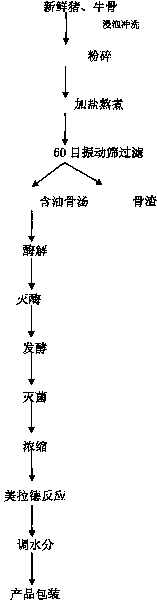

[0022] A kind of preparation method of natural pig, beef bone flavor essence, mainly comprises the following steps:

[0023] (1) Take by weighing 1000kg of fresh pork bones, fully soak and rinse with clear water; powder the pork bone meal with a pulverizer;

[0024] (2) Add twice the volume of pork bone powder to the brine containing 5wt% NaCl, boil for 6 hours under normal pressure, filter, and separate bone fluid and bone residue;

[0025] (3) Take the bone fluid and cool it down to 58°C and add 5kg of compound enzyme A for enzymolysis for 4 hours, then add 7kg of compound enzyme B to continue the enzymatic hydrolysis for 7 hours; after the end, quickly raise the temperature to 90°C and keep it warm for 10 minutes to inactivate the enzyme to obtain the enzymatic hydrolysis solution; The composite enzyme A is a mixture of papain, bromelain and neutral protease, and the composite enzyme B is a mixture of bromelain, neutral protease and subtilisin;

[0026] (4) Cool down to 30...

Embodiment 2

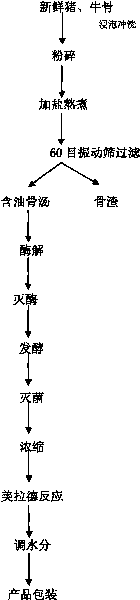

[0030] A kind of preparation method of natural pig, beef bone flavor essence, mainly comprises the following steps:

[0031] (1) Take 1000kg of fresh pork bones, fully soak and rinse them with clear water, and use a pulverizer to powder the pork bones;

[0032] (2) Add twice the volume of pork bone powder to the brine containing 8wt% NaCl, boil for 5 hours under normal pressure, filter, and separate bone fluid and bone residue;

[0033] (3) Take the bone fluid and cool it down to 58°C and add 5kg of compound enzyme A for enzymolysis for 4 hours, then add 7kg of compound enzyme B to continue the enzymatic hydrolysis for 7 hours; after the end, quickly raise the temperature to 90°C and keep it warm for 10 minutes to inactivate the enzyme to obtain the enzymatic hydrolysis solution; The compound enzyme A is a mixture of papain, neutral protease and alkaline protease, and the compound enzyme B is a mixture of bromelain and subtilisin;

[0034] (4) Cool down to 30-35°C, adjust the...

Embodiment 3

[0038] A kind of preparation method of natural pig, beef bone flavor essence, mainly comprises the following steps:

[0039] (1) Weigh 1000kg of fresh bovine bones, fully soak and rinse with clean water. Use a pulverizer to make bovine bone meal into powder;

[0040] (2) Add 3 times the volume of bovine bone powder into brine containing 4wt% NaCl, boil for 5 hours under normal pressure, filter, and separate bone fluid and bone residue;

[0041] (3) Take the bone fluid and cool it down to 58°C and put in 4.5kg of compound enzyme A for 4 hours, then add 7.5kg of compound enzyme B to continue the enzymatic hydrolysis for 6 hours; after the end, quickly raise the temperature to 90°C and keep it warm for 10 minutes to inactivate the enzyme and obtain the enzymatic hydrolysis Liquid; the composite enzyme A is selected from papain, bromelain, neutral protease and alkaline protease, and the composite enzyme B is selected from bromelain, neutral protease and subtilisin;

[0042](4) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com