Coal-to-natural gas catalyst and manufacturing method thereof

A technology for producing natural gas from coal and a manufacturing method, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Problems such as poor process and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

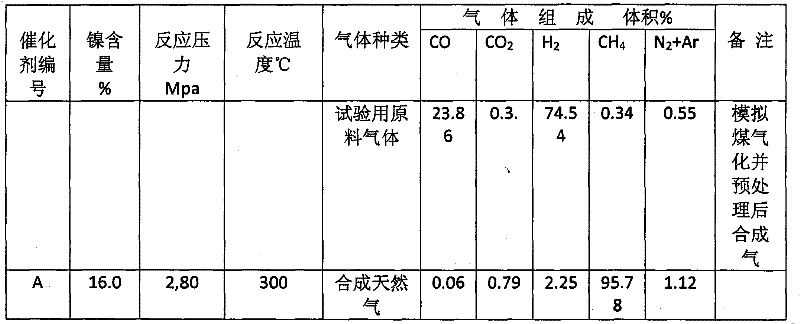

Examples

Embodiment 1

[0028] 60g Al 2 o 3 , 10g CaCO 3 , 6g TiO 2 , 2g La 2 O3, 1g of graphite and 15ml of water are fully mixed, extruded into strips, dried at 110-150°C for 2 hours, and then calcined at 1000°C for 4 hours to make the catalyst carrier.

[0029] Impregnation of the obtained catalyst support: the catalyst support was immersed in the prepared nickel nitrate aqueous solution with a specific gravity of 1.55, the immersion temperature was 85° C., and the immersion time was 30 minutes. The impregnated catalyst was taken out and dried at 150° C. for 2 hours, and then decomposed at 500° C. for 2 hours.

[0030] The catalyst impregnated and decomposed once is subjected to repeated impregnation and decomposition for the second time according to the conditions required in the above impregnation and decomposition process, so as to obtain the coal-to-natural gas catalyst. The Ni content is 15.3%.

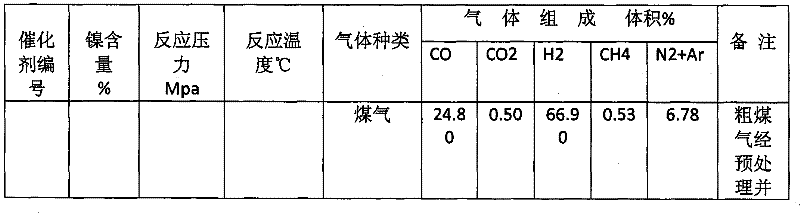

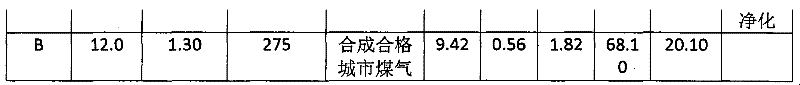

Embodiment 2

[0032] 63g Al 2 o 3 , 10.2g CaCO 3 , 6.6g TiO 2 , 2.1g La 2 o 3 , 1.3g of graphite and 15ml of water are fully mixed, extruded into strips, dried at 110-150°C for 2 hours, and then calcined at 800-1200°C for 4 hours to make the catalyst carrier.

[0033] Impregnation of the obtained catalyst support: the catalyst support was immersed in the prepared nickel nitrate aqueous solution with a specific gravity of 1.45, the immersion temperature was 90° C., and the immersion time was 1 hour. The impregnated catalyst was taken out and dried at 170°C for 2 hours, and then decomposed at 550°C for 2 hours.

[0034] The catalyst impregnated and decomposed once is subjected to repeated impregnation and decomposition for the second time according to the conditions required in the above impregnation and decomposition process, so as to obtain the coal-to-natural gas catalyst. The Ni content is 9.2%.

Embodiment 3

[0036] 58g Al 2 o 3 , 9.6g CaCO 3 , 5.88g TiO 2 , 1.8g La 2 o 3 1. 1g of graphite and 15ml of water are fully mixed, extruded into strips, dried at 110-150°C for 3 hours, and then calcined at 800-1200°C for 4 hours to make a catalyst carrier.

[0037] Impregnation of the obtained catalyst carrier: the catalyst carrier was immersed in the prepared nickel nitrate aqueous solution with a specific gravity of 1.35, the immersion temperature was 85° C., and the immersion time was 1 hour. The impregnated catalyst was taken out and dried at 180°C for 2 hours, and then decomposed at 550°C for 3 hours to obtain a coal-to-natural gas catalyst. Ni content 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com