Z-shaped tower type highly-efficient dry sand cooling device with internal water-cooled tube and external water-cooled tube

A cooling device and water-cooled tube technology, which is applied in casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limited application range, and achieve the effects of improving cooling efficiency, facilitating heat exchange, and increasing heat

Inactive Publication Date: 2013-02-13

SHANXI MOFAN MACHINERY MFG

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, in order to evaporate quickly, it can only be sprayed on the high-temperature molding sand just after falling sand, and the scope of use is limited.

At the same time, the water mist can only contact the sand layer on the surface, and the lower layer of sand cannot be cooled.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

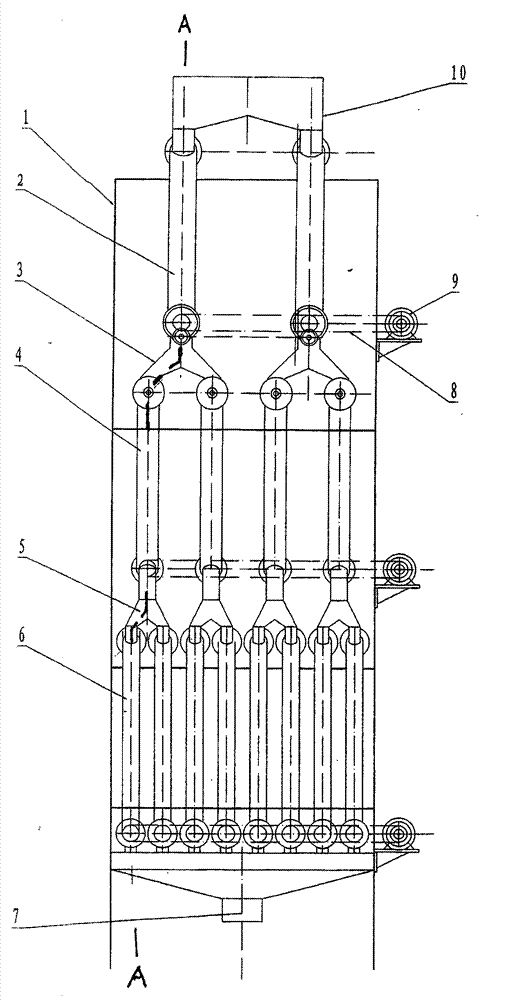

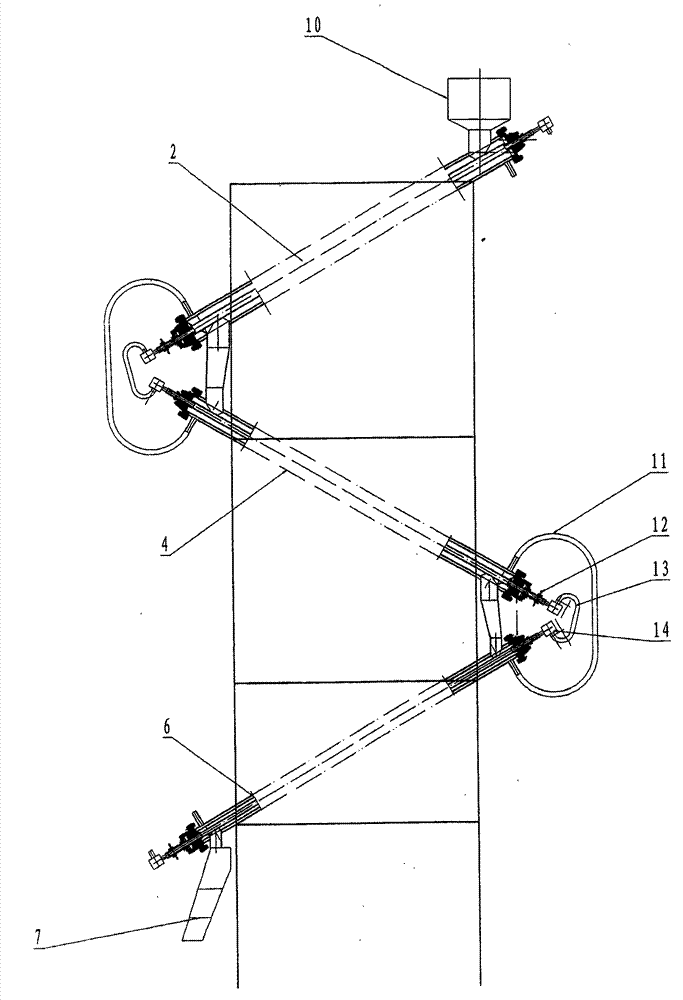

[0013] The first cold water pipe 2, the second cold water pipe 4, and the third cold water pipe 6 are arranged in a Z-shaped tower, and the inclination angle between them is 30 degrees greater than the angle of repose of the molding sand.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

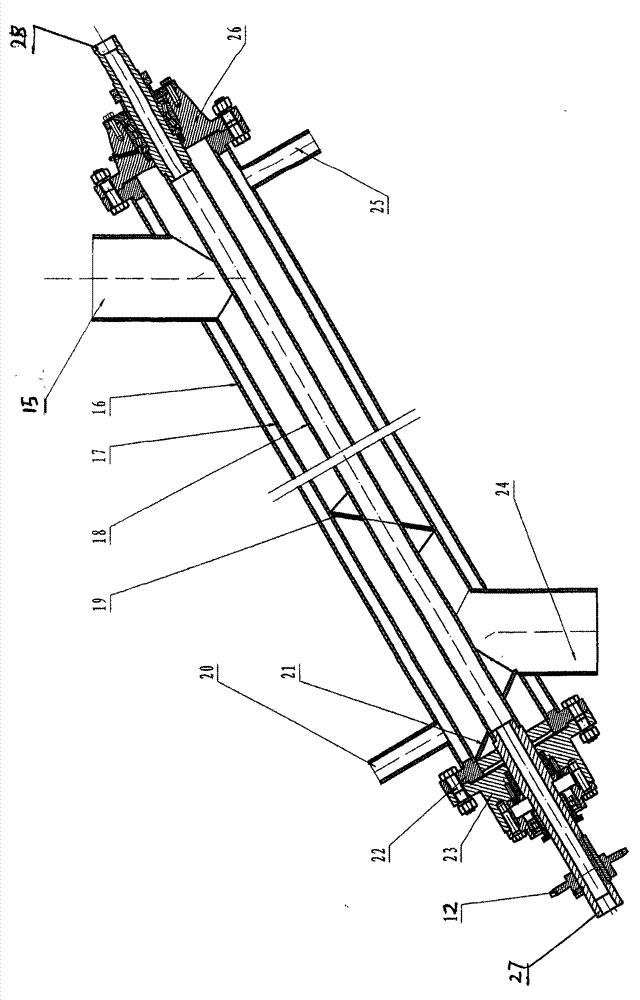

The invention relates to a Z-shaped tower type highly-efficient dry sand cooling device with an internal water-cooled tube and an external water-cooled tube. The upper end of a tower bracket (1) is provided with a general sand inlet port (10); the lower end of the sand inlet port is connected with a first cold water tube (2) which is connected with a second cold water tube (4) through a first sand separating tube (3); the second cold water tube (4) is connected with a third cold water tube (6) through a second sand separating tube (5); the lower end of the third cold water tube (6) is connected with a general sand outlet port (7); the tower type bracket (1) is provided with a motor (9) with a chain wheel, and the motor is connected with a shaft sprocket (12) through a chain (8); each cold water tube is internally provided with an external tube (16) and an internal tube (17); a centre shaft is provided with a stirring gear (19) and a spiral plate (21); and each cold water tube is respectively provided with an external tube water inlet port (20), an external tube water outlet port (25), a centre shaft water inlet port (27) and a centre shaft water outlet port (28). In the invention, water which has large heat capacity is adopted as a medium and can take away large quantity of heat, the internal water-cooled tube and the external water-cooled tube are adopted, and thus the cooling efficiency is improved.

Description

technical field [0001] The invention belongs to a device for reducing the temperature of molding sand in lost foam casting, V-method casting, etc., and in particular relates to a Z-shaped tower type high-efficiency dry sand cooling device with internal and external water cooling tubes. Background technique [0002] Casting processes such as lost foam and V method all use dry sand molding. The temperature of the molding sand just dropped from the box in continuous production is often as high as 300°C-500°C, while the plastic film and EPS mold that are in contact with or close to the molding sand during molding are 70°C. Left and right are softened and deformed. If the temperature of the continuously used molding sand is not lowered below 60°C quickly, it can no longer be used for molding. Therefore, the problem of sand temperature reduction has become the main factor restricting the continuous, large-scale and large-scale production of these casting processes. There are thr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22C5/08

Inventor 刘成文靳文虎

Owner SHANXI MOFAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com