Laser synthesis method for barium tetratitanate

A technology of barium tetratitanate and laser synthesis, which is applied in the field of preparation of microwave dielectric ceramic materials, can solve the problems of long preparation time and high energy consumption, and achieve the effects of low cost, low energy consumption and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] BaCO 3 and TiO 2 The powders were mixed in a molar ratio of 1:4, ground in an agate mortar for 1 hour, dried at 150°C for 2 hours, and then ground in an agate mortar for 2 hours. Press the fully mixed powder into a compact under a pressure of 20Mpa, and hold the pressure for 60s. The green body has a diameter of 14mm and a thickness of 3mm.

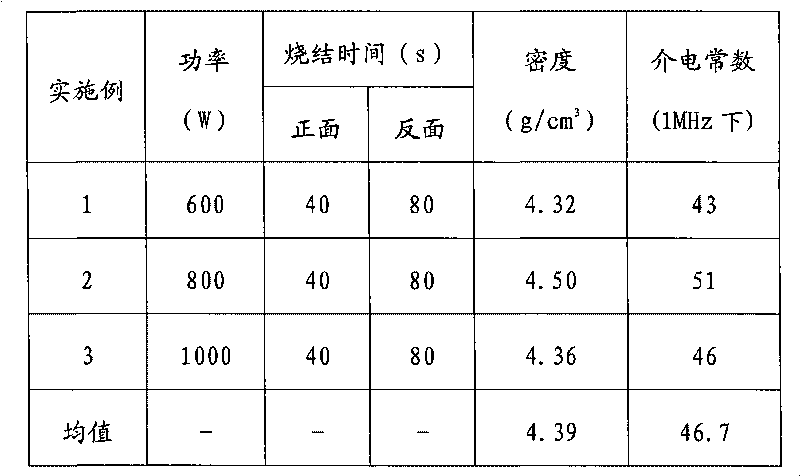

[0025] Place the green body on the sample stage, and use CO 2 The laser beam directly irradiates one side of the sample for 40s, and the opposite side for 80s. During this process, the laser power is 600W, and the defocus distance is 120mm. The prepared samples were processed and tested for density and dielectric constant. The test results are shown in Table 1.

Embodiment 2

[0027] BaCO 3 and TiO 2 The powders were mixed in a molar ratio of 1:4, ground in an agate mortar for 1 hour, dried at 150°C for 2 hours, and then ground in an agate mortar for 2 hours. The fully mixed powder is compacted under a pressure of 20MPa, and the pressure is maintained for 60s. The green body has a diameter of 14mm and a thickness of 2mm.

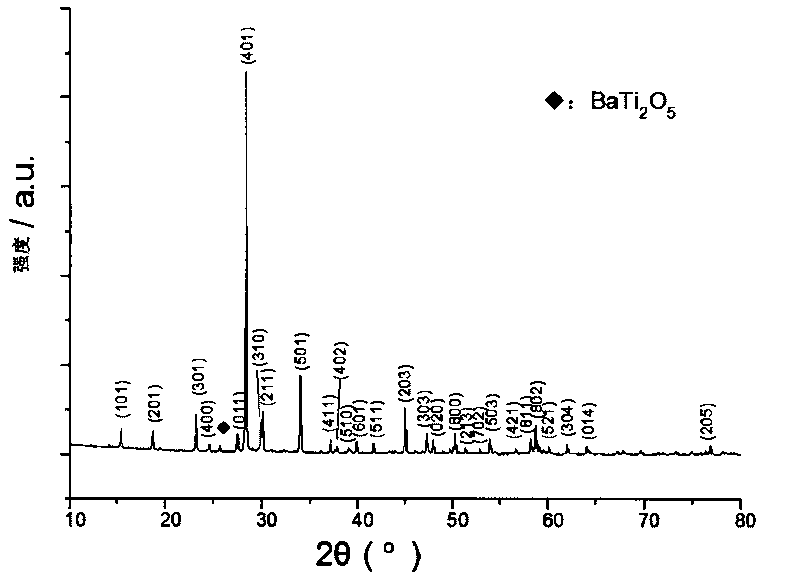

[0028] Place the green body on the sample stage, and use CO 2 The laser beam directly irradiates one side of the sample for 40s, and the opposite side for 80s. During this process, the laser power is 800W, and the defocus distance is 120mm. The prepared samples were processed and subjected to X-ray diffraction (XRD), scanning electron microscope (SEM), density and dielectric constant tests. The test results are shown in Table 1.

[0029] The XRD spectrum of the obtained sample is shown in figure 1 , the SEM photograph of its cross-section is shown in figure 2 . XRD spectrogram shows that the present invention can make the...

Embodiment 3

[0031] BaCO 3 and TiO 2 The powders were mixed in a molar ratio of 1:4, ground in an agate mortar for 1 hour, dried at 150°C for 2 hours, and then ground in an agate mortar for 2 hours. The fully mixed powder is compacted under a pressure of 20MPa, and the pressure is maintained for 60s. The green body has a diameter of 14mm and a thickness of 4mm.

[0032] Place the green body on the sample stage, and use CO 2 The laser beam directly irradiates one side of the sample for 40s, and the opposite side for 80s. During this process, the laser power is 1000W, and the defocus distance is 120mm. The prepared samples were processed and tested for density and dielectric constant. The test results are shown in Table 1.

[0033] Table 1 shows process parameters and sample performance test results in Examples 1-3. The sample average density prepared by the present invention is 4.39g / cm 3 , which is 96.9% of the theoretical density value; the average value of the dielectric constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com