Preparation method and application of immobilized acid urease for wine

A technology for acid urease and wine, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, etc. It can solve the problems of unstable free enzymes, difficult separation and recovery of enzymes, variability and inactivation, etc. Achieve high urea removal rate, easy recycling, and reduce urea content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

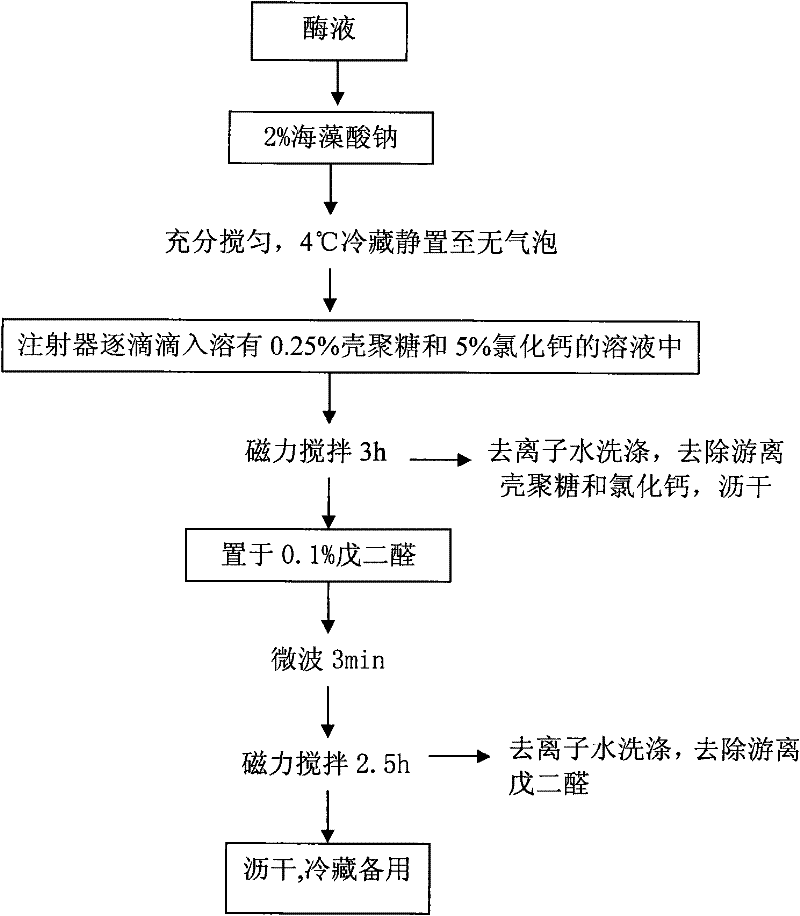

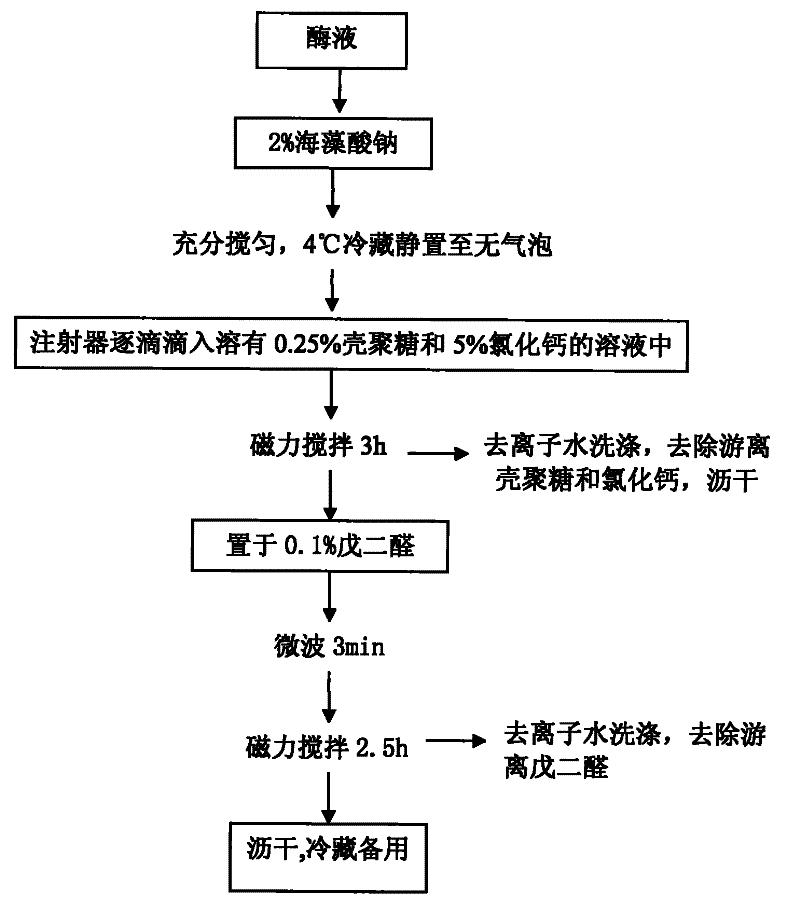

[0045] Example 1: Dissolve 2g of sodium alginate in 100mL of free acid urease enzyme solution, stir fully with a glass rod, stir well, place it in a refrigerator at 4°C and refrigerate until there are no bubbles in the solution, drop 500mL of the solution with a syringe. In a solution containing 0.25% chitosan and 5% calcium chloride, place it on a magnetic stirrer for 3 hours, wash it with deionized water, remove free chitosan and calcium chloride, drain, and remove the immobilized small The spheres were placed in 0.1% glutaraldehyde, the mass of the immobilized spheres / volume of glutaraldehyde was controlled to be 2 g / mL, and after 3 min of microwave, it was placed on a magnetic stirrer for magnetic stirring for 2.5 h (covered with an opaque container to prevent glutaraldehyde). The dialdehyde changes color upon seeing light), washed with deionized water to remove free glutaraldehyde (detected by ultraviolet spectrophotometry), drained, refrigerated for later use, to obtain 5...

Embodiment 2

[0046] Example 2: Dissolve 3.6g of sodium alginate in 180mL of free acid urease enzyme solution, stir well with a glass rod, stir well, place it in a refrigerator at 4°C and refrigerate until there are no bubbles in the solution, drop into 900mL dropwise with a syringe Dissolved in a solution of 0.25% chitosan and 5% calcium chloride, placed it on a magnetic stirrer for 3 hours, and washed it with deionized water to remove free chitosan and calcium chloride. The pellets were placed in 0.1% glutaraldehyde, and the mass of the immobilized pellets / volume of glutaraldehyde was controlled to be 2 g / mL. After microwave for 3 min, it was placed on a magnetic stirrer for 2.5 h (covered with an opaque container to prevent Glutaraldehyde changes color upon exposure to light), washed with deionized water to remove free glutaraldehyde (detected by ultraviolet spectrophotometry), drained, refrigerated for later use, to obtain 89.58g of immobilized acid urease for wine, loaded into a flow de...

Embodiment 3

[0047] Example 3: Dissolve 2g of sodium alginate in 100mL of free acid urease enzyme solution, fully stir with a glass rod, stir evenly, place it in a refrigerator at 4°C and refrigerate until there are no bubbles in the solution, drop into 500mL of solution with a syringe dropwise. In a solution containing 0.25% chitosan and 5% calcium chloride, place it on a magnetic stirrer for 3 hours, wash it with deionized water, remove free chitosan and calcium chloride, drain, and remove the immobilized small The spheres were placed in 0.1% glutaraldehyde, the mass of the immobilized spheres / volume of glutaraldehyde was controlled to be 2g / mL, and after microwave for 3min, placed on a magnetic stirrer for 2.5h (covered with an opaque container to prevent glutaraldehyde) The dialdehyde changes color upon exposure to light), washed with deionized water to remove free glutaraldehyde (detected by UV spectrophotometry), drained, refrigerated for later use, to obtain 50.56g of immobilized aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com