Compressed air engine and application thereof

A technology of compressed air and engine, applied in the direction of machine/engine, motor-driven engine, rotorcraft, etc., can solve the problems of obtaining vertical take-off and landing and hovering, power loss, difficult aircraft, etc., to achieve simple structure and reduce construction costs and construction time, installation location and flexible effect of adding or removing replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

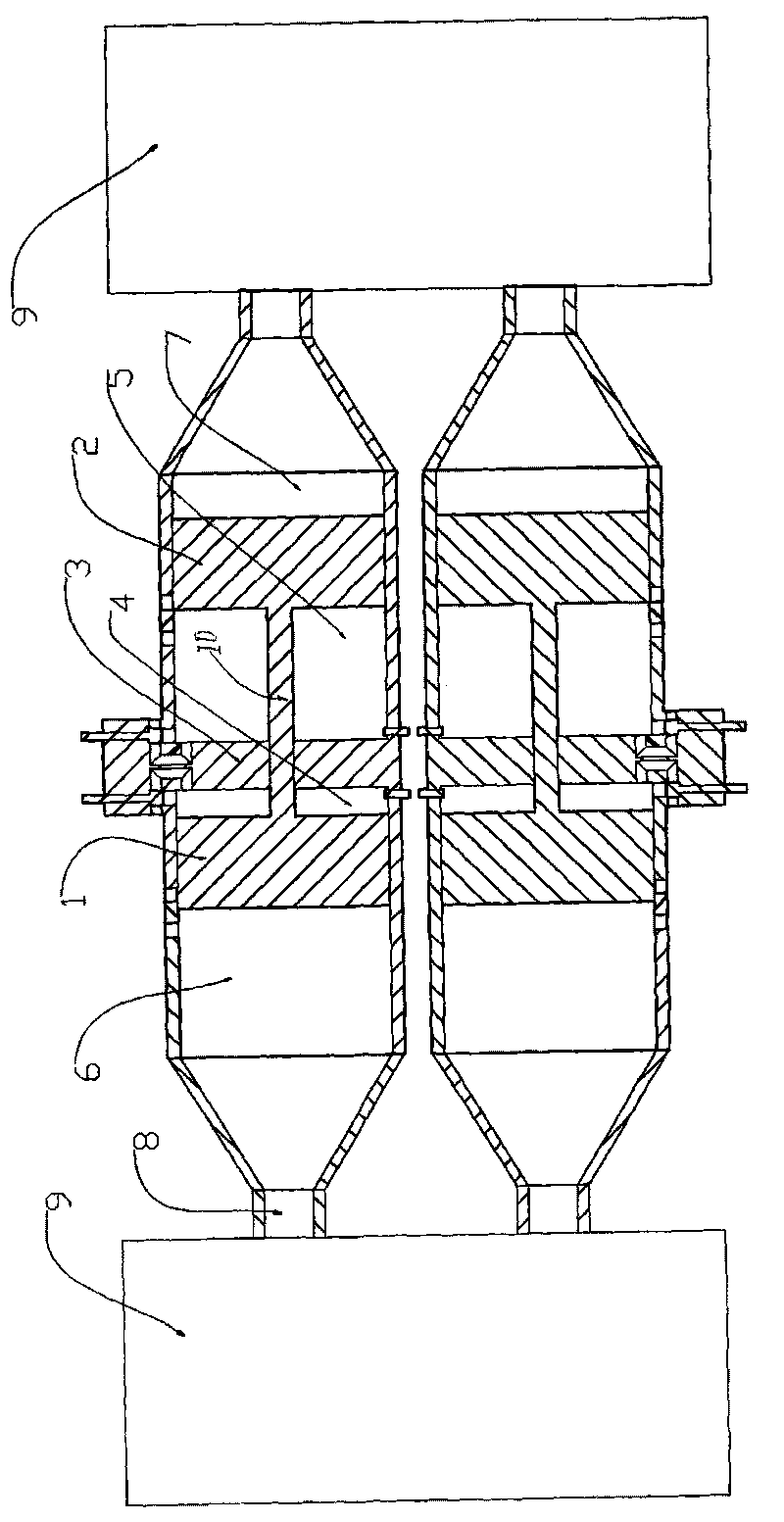

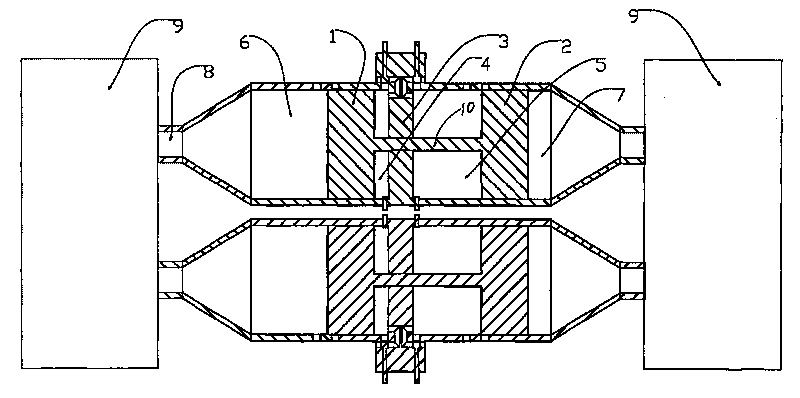

[0018] In the accompanying drawings, the pistons (1) and (2) in the piston engine are spaced at a certain distance and fixedly connected in series; the sealed partition (3) between them divides the cylinder into two combustion chambers (4) and (5) And two air compression chambers (6) and (7), and the pistons (1) and (2) are opposite to each other; when the piston (2) performs suction and power strokes, it drives the piston (1) to exhaust and compression stroke, and vice versa. When the pistons (1) and (2) of the piston engine do work, the air in the two air compression chambers (6) and (7) is continuously pressed into the air storage tank (9) through the check valve (8), and then passed through The nozzles installed in all directions of the moving object are ejected to obtain power.

[0019] In order to increase the gas production per unit time of a single piston engine, the diameters of the pistons (1) and (2) can be increased, or the length of the cylinder and the stroke of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com