Plasma microstrip switch

A plasma and microstrip technology, used in electrical components, circuits, waveguide devices, etc., can solve the problems of slow switching speed and unsatisfactory power characteristics, and achieve the effect of good power characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

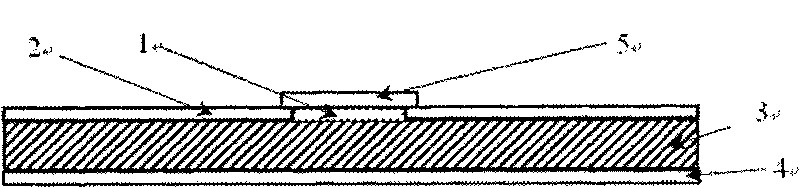

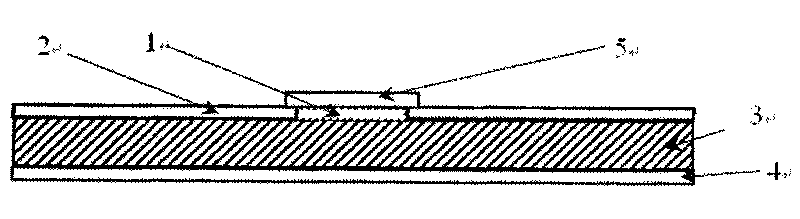

[0013] Below in conjunction with accompanying drawing, the present invention will be further described

[0014] Such as figure 1 As shown, the substrate of the microstrip circuit, that is, the dielectric substrate 3 is made of silicon material, and the grounded copper film 4 is placed under the dielectric substrate 3. The microstrip transmission line 2 is a copper strip with a thickness of 0.1 mm and a width of 2 mm. The gap between the microstrip transmission lines is 1 The width is 5mm. Plasma generator 5 is placed on the microstrip gap 1, it is made up of two copper electrodes with a thickness of 1.5mm and a width of 7mm, the electrode spacing is 4mm, and the electrodes are connected with the control power supply by wires; except for the opposite surfaces of the two copper electrodes, The rest of the surface is covered with insulating glue, and the lower end of the electrode is fixed on the dielectric substrate 3 with insulating glue, so that the discharge occurs in a limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com