Manufacture of high-voltage electrochemical capacitor

A manufacturing method and capacitor technology, applied in the direction of electrolytic capacitors, capacitors, electrode manufacturing, etc., to achieve the effects of low cost, reduced resistance, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Use plant material, such as wood, in an inert atmosphere, such as argon, for carbonization treatment. The treatment condition is that the treated product is immersed in molten KOH at 450 ° C for 4 hours, and then in the temperature range of 850 ° C, with ZnCl 2 As a catalyst, NaOH was used as an activator to activate for 4 hours, and then to perform secondary activation with high-temperature water vapor to obtain activated carbon materials with special structure and surface characteristics.

[0035]The porous activated carbon material prepared above is used as an electrode material, conductive graphite is used as a conductive agent, polytetrafluoroethylene resin is used as a binder, mixed according to a ratio of 75%: 20%: 5%, and dissolved in an inorganic solvent such as deionized water, and fully stirred to prepare electrode slurry.

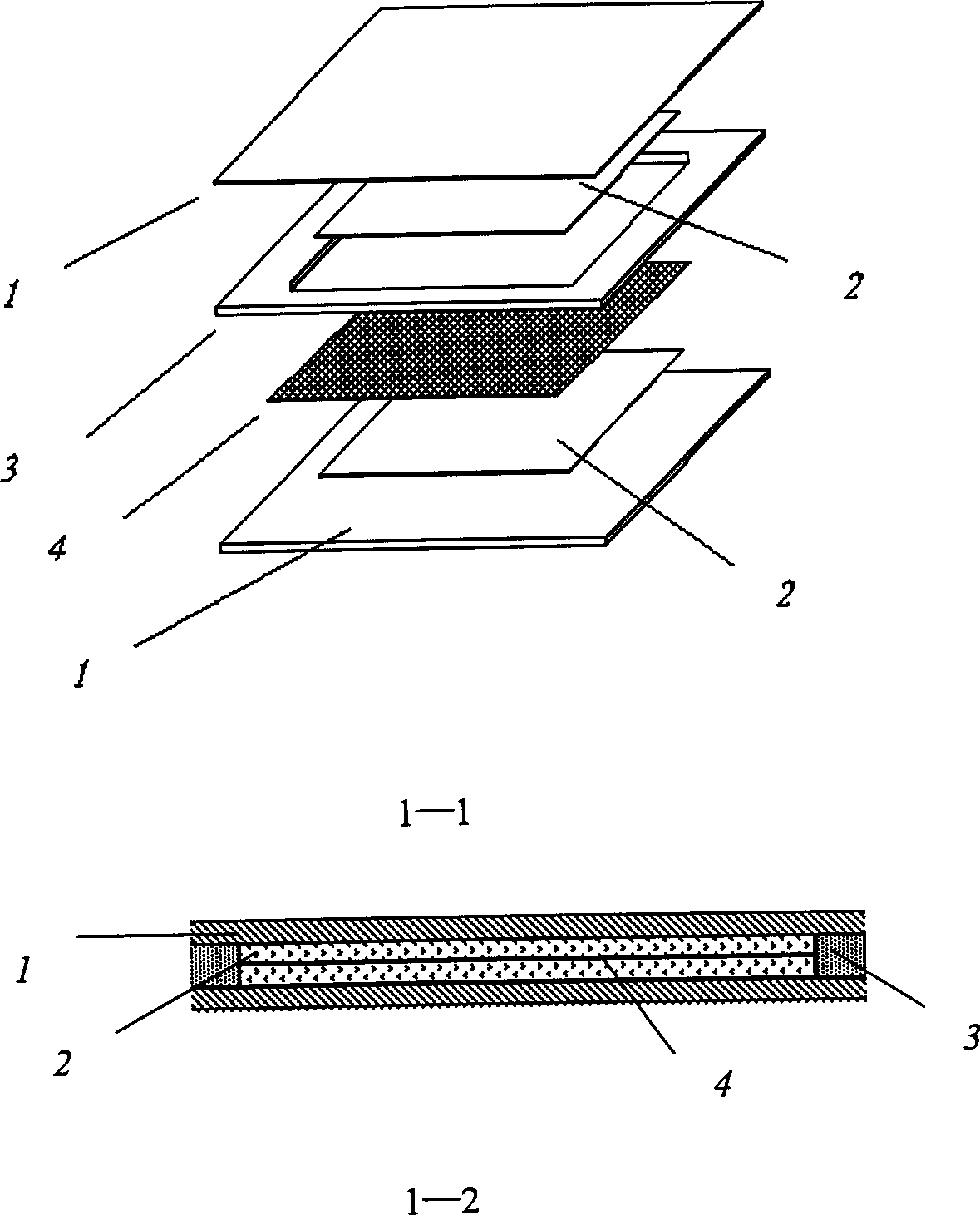

[0036] The electrode slurry with a certain viscosity is coated on the nickel mesh collector, dried, and pressed to prepare a positive el...

Embodiment approach 2

[0040] Mineral materials, such as bituminous coal, are carbonized in an inert atmosphere such as a nitrogen atmosphere, and the processed product is immersed in molten NaOH at 480°C for 4 hours, and then treated with ZnCl in the temperature range of 880°C 2 As a catalyst, NaOH was used as an activator to activate for 4 hours, and then high-temperature water vapor was used for secondary activation to obtain activated carbon materials with special structure and surface characteristics.

[0041] The porous activated carbon material prepared above is used as the electrode material, acetylene black is used as the conductive agent, and a mixture of polytetrafluoroethylene resin and sodium carboxymethyl cellulose is used as the binder, mixed according to the ratio of 75%: 20%: 5% (poly Tetrafluoroethylene resin and sodium carboxymethyl cellulose (the proportion of the two is 3:2) is dissolved in deionized water, and fully stirred to prepare electrode slurry.

[0042] The electrode sl...

Embodiment approach 3

[0044] The preparation of the electrode material is to dry the electrode slurry, remove part of the water, use the roller machine to press it into an electrode diaphragm, and use a hydraulic press to press it together with the aluminum mesh and the copper mesh, and dry it in a vacuum oven. At the same time, the negative electrode is welded into aluminum foil on the aluminum mesh and the copper mesh as the lead-out electrode.

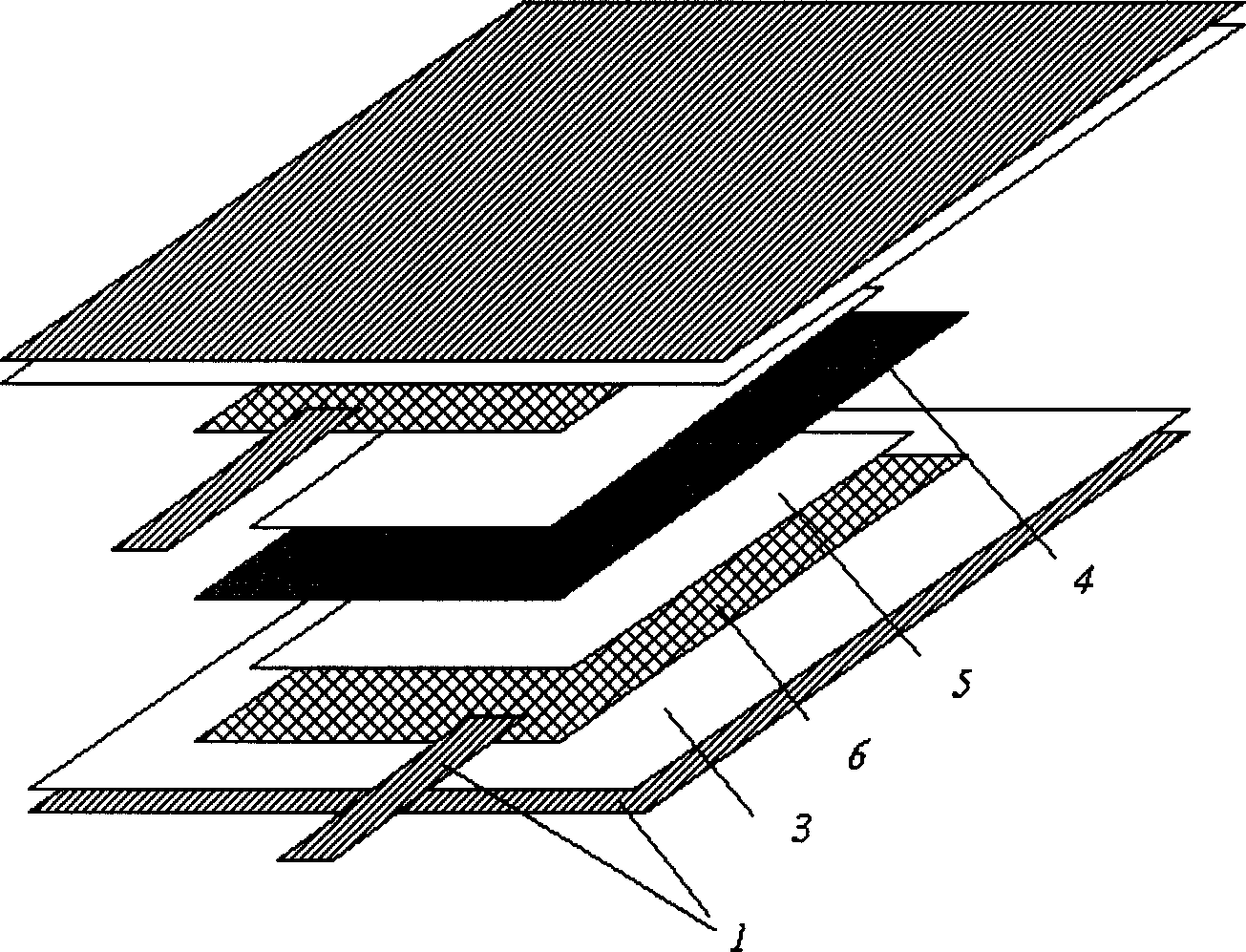

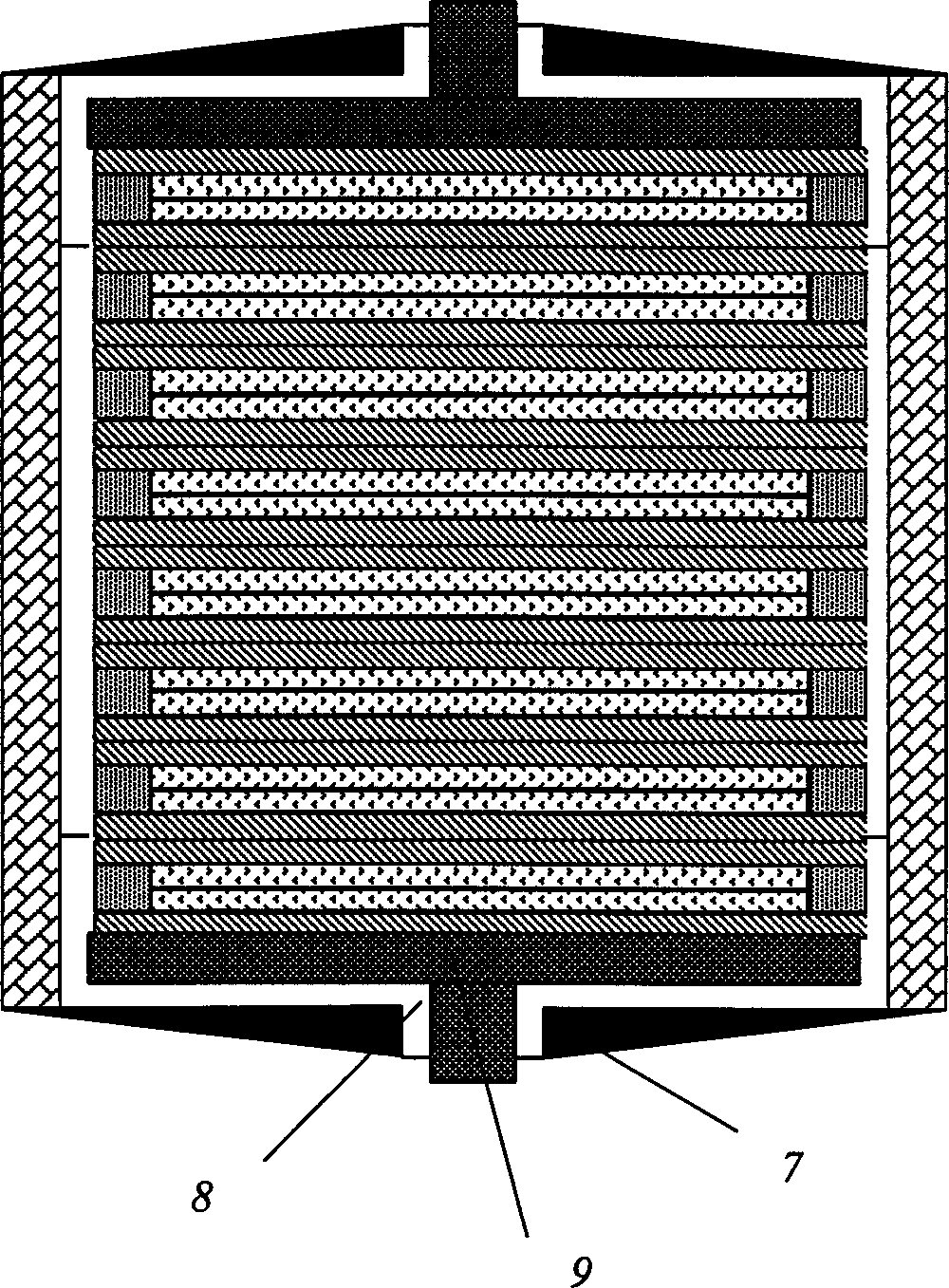

[0045] Select a strong alkaline substance, such as LiOH dissolved in a non-ionic solvent as the electrolyte. Glass fiber paper is selected as the separator, the electrodes and the separator are fully immersed in the electrolyte, and then the electrolyte is dried, and the conductive rubber is used as the packaging shell and electrode collector, and the conductive rubber diaphragm, electrode, insulating plastic, and separator are placed according to the figure 2 The order is stacked and placed, and the surrounding edges of the conductive rubber diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com