Large-liquid holdup catalytic-reaction rectifying tower plate

A catalytic rectification column and catalytic reaction technology are applied in the field of structural improvement of rectification trays, which can solve the problems of limited catalyst loading and contact area, small liquid hold-up on trays, short residence time, etc. The effect of large area and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

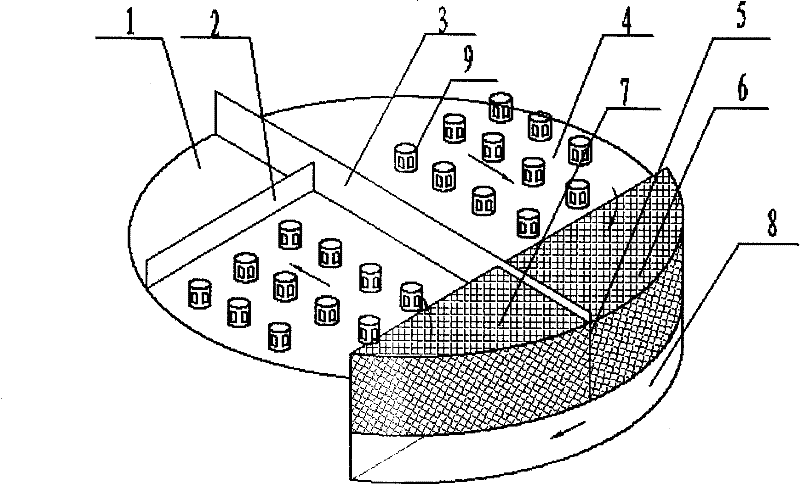

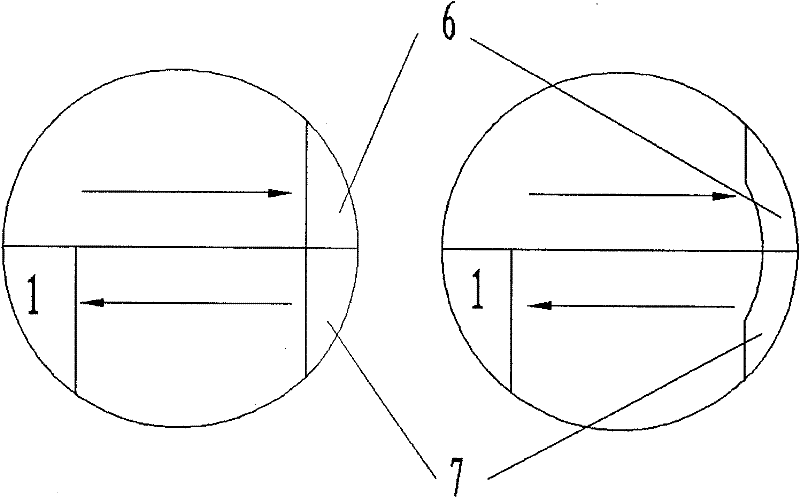

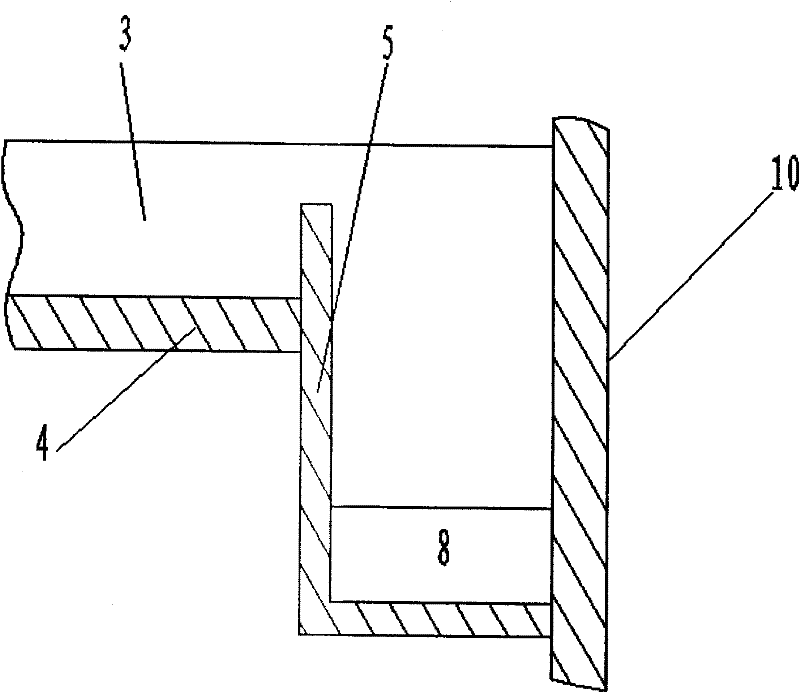

Embodiment 1

[0028] A methyl acetate reactive distillation column in a chemical plant used high-efficiency valve trays before the transformation. Now the column diameter, plate spacing and number of trays remain unchanged, and the trays of the present invention are used for replacement and reconstruction. The tower diameter is 2.4m, the plate spacing is 550mm, the area of the downcomer 1 accounts for 5% of the total area of the tower, the cross-sectional area of the holding tank 5 is 20% of the total area of the plate, and the height is 300mm, the horizontal flow channel in the holding tank 5 8 is 100mm high. The partition plate 3 has a height of 300mm. The partition plate extends into the liquid holding tank, 100mm from the bottom of the liquid holding tank 5, and is connected with the tower wall 10. There is a grid support at 100mm from the bottom of the liquid holding tank, on which a 500Y plate corrugated structured packing with a porosity of 97% is placed, and the pressure ri...

Embodiment 2

[0030]The butyl acetate reactive distillation column of a certain chemical plant adopts the tray of the present invention in design. The tower diameter is 2m, 60 actual trays, the plate spacing is 600mm, the area of the downcomer 1 accounts for 8% of the total area of the tower, the cross-sectional area of the holding tank 5 is 30% of the total area of the tray, and the height is 400mm. The horizontal channel 8 in the 5 is high 150mm. The partition plate 3 has a height of 300mm. The partition plate 3 extends to the inside of the liquid holding tank 5 at a distance of 150 mm from the bottom of the liquid holding tank 5 , and is connected with the tower wall 10 . There is a grid support at 150mm from the bottom of the liquid holding tank 5, on which a 250Y plate corrugated structured packing with a porosity of 68% and a sulfonic acid resin catalyst wrapped in a wire mesh is placed, and the pressure ring is covered on the top, and the entire catalytic reaction zone The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com