Novel method for separating and purifying sucralose-6-ethyl ester

A technology for purifying sucralose and sucralose, which is applied in the direction of chemical instruments and methods, esterified saccharides, sugar derivatives, etc., can solve problems such as increased production costs, incomplete extraction, and material loss, so as to reduce the cost of products Loss, increase of extraction rate, effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

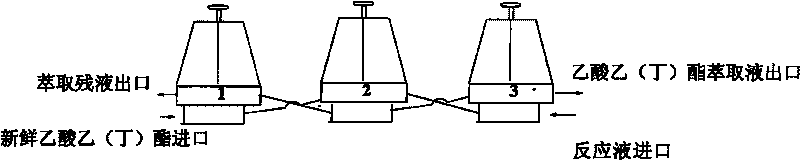

[0022] Take 100mL of the aqueous solution containing sucralose-6-ethyl ester and other by-products prepared by the above method, and use three Φ20 annular gap centrifugal extractors to form a series countercurrent extraction process (see the attached figure 1 ), the extraction solvent is 80mL of fresh ethyl acetate, the flow control of the aqueous solution is 2L / h, the operating flow ratio (organic phase / water phase) is controlled to be 0.8: 1, the rotating speed is 1800r / min, and the ethyl acetate extract is concentrated to dryness Obtain 42.5g content and be 52% syrup-like substance (containing 22.1g sucralose-6-ethyl ester), use 30mL of 1% diethyl ether (volume ratio) water crystallization to obtain sucralose 6-ethyl ester crude product, gained crude product with 35mL Recrystallized from a mixed solvent of ethyl acetate and water (ethyl acetate:water=1:0.5) with a content of more than 98% of sucralose-6-ethyl ester (the yield of separation and purification was 46.2%).

Embodiment 2

[0024] Take 100mL of the aqueous solution containing sucralose-6-ethyl ester and other by-products prepared by the above method, and use 4 sets of Φ20 ring-gap centrifugal extractors to form a series countercurrent extraction process. The extraction solvent is 150mL of fresh ethyl acetate. The flow control is 3L / h, the operating flow ratio (organic phase / water phase) is controlled to be 1.5: 1, and the rotating speed is 1800r / min, and the ethyl acetate extract is concentrated to dryness to obtain 43.1g content of 52.5% syrupy substance (containing 22.6g sucralose-6-ethyl ester), crystallized with 30mL of 2% diethyl ether (volume ratio) water to obtain the crude product of sucralose-6-ethyl ester, and the resulting crude product was recrystallized with a mixed solvent of 35mL ethyl acetate and water ( Ethyl acetate: water = 1:0.5) with a content of more than 98% of sucralose-6-ethyl ester (separation and purification yield of 49.2%).

Embodiment 3

[0026] Take 100 mL of the aqueous solution containing sucralose-6-ethyl ester and other by-products prepared by the above method, and use 3 sets of Φ20 annular gap centrifugal extractors to form a series countercurrent extraction process. The extraction solvent is 100 mL of fresh ethyl acetate, and the aqueous solution The flow control is 4L / h, the operating flow ratio (organic phase / water phase) is controlled to be 1: 1, and the rotating speed is 1800r / min, and the ethyl acetate extract is concentrated to dryness to obtain 42.8g content of 52.5% syrupy substance (containing 22.5g sucralose-6-ethyl ester), crystallized with 35mL of water containing 1% ether to obtain the crude product, and the resulting crude product was recrystallized with a mixed solvent of 30mL ethyl acetate and water (ethyl acetate: water = 1: 0.6) content More than 98% of sucralose-6-ethyl ester (separation and purification yield is 48.2%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com