Method for processing oil grooves in inner bores of copper bearing bush

A bearing bushing and copper processing technology, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of large cutting force, unsuitable for mass production requirements, high surface roughness, etc., and meet the requirements of mass production and high Effects on process quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

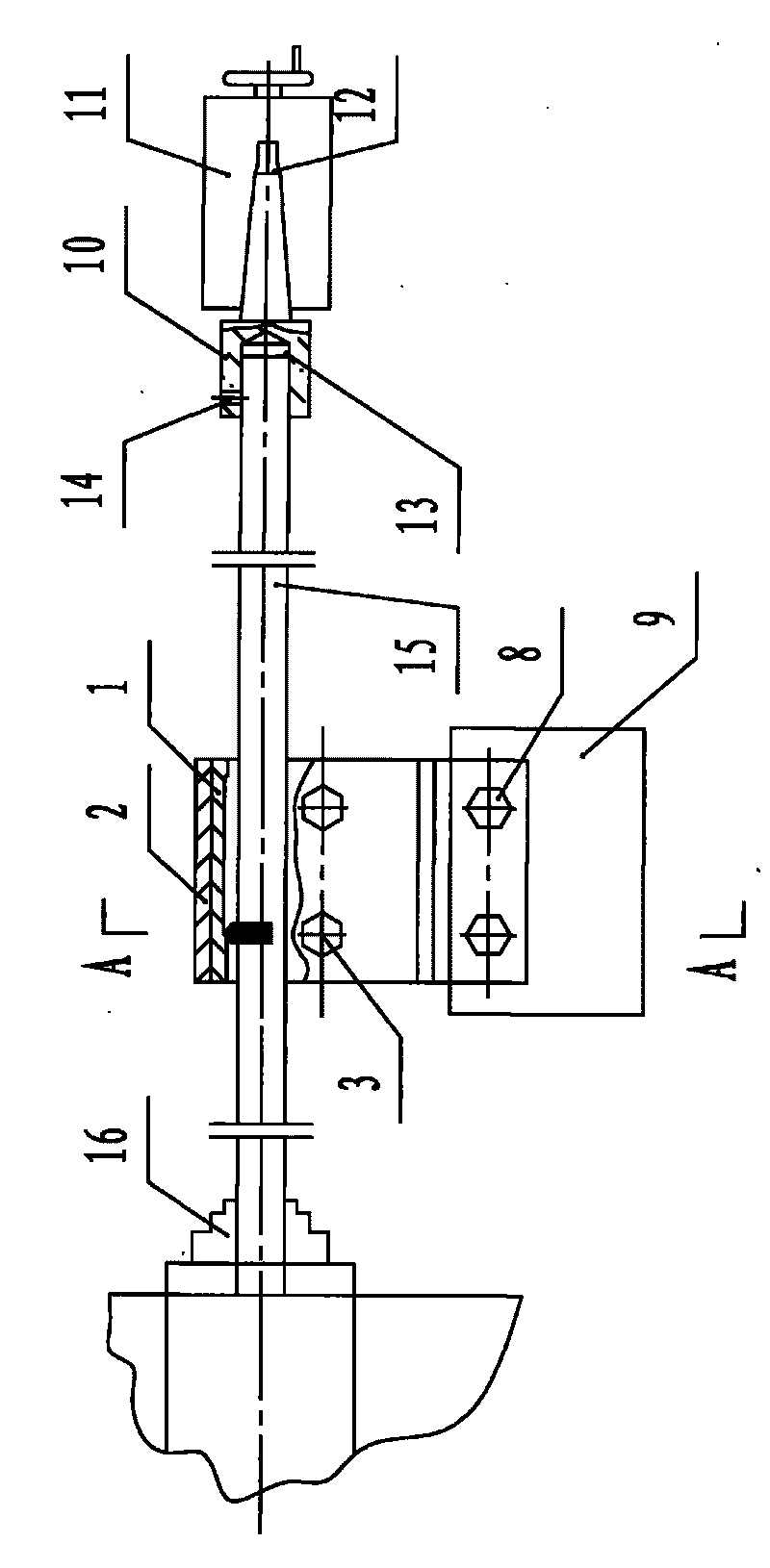

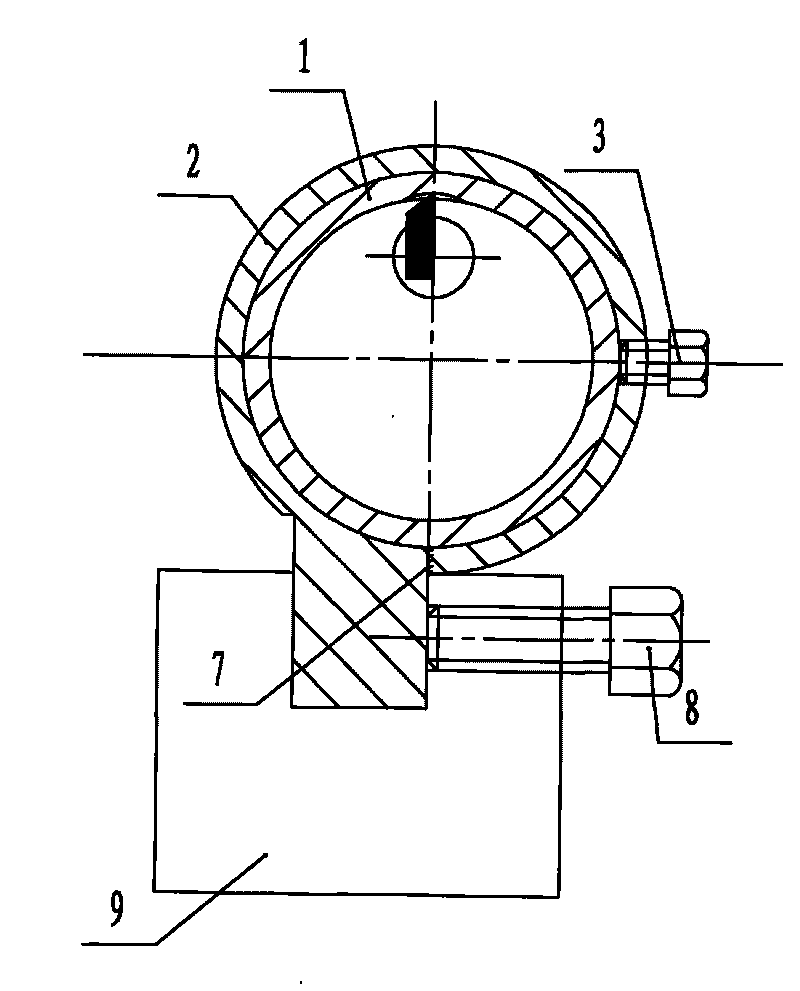

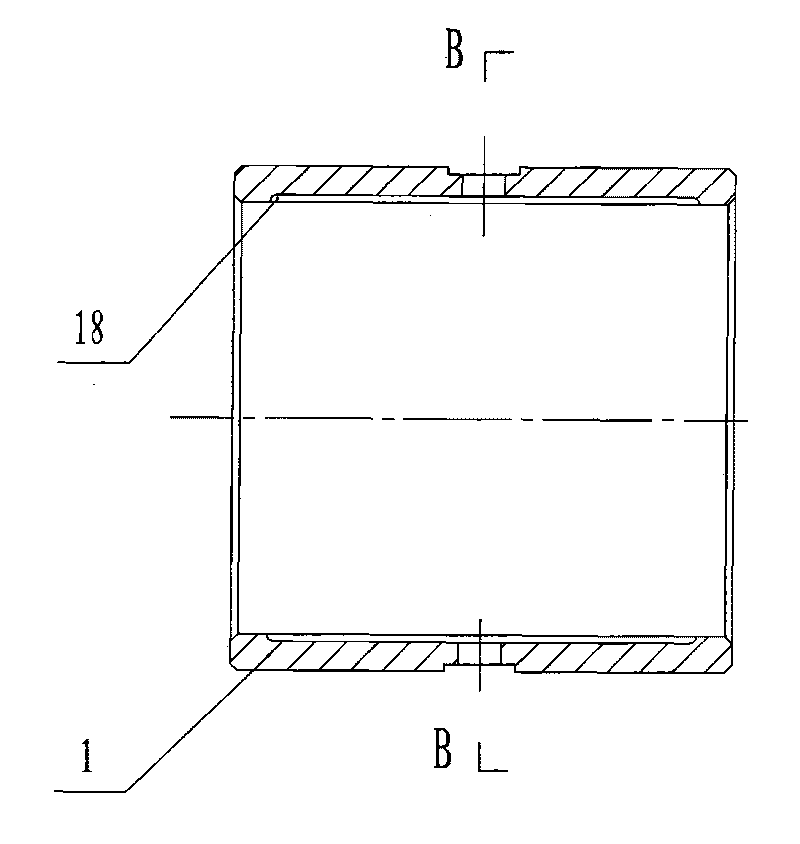

[0022] Figure 1 to Figure 8 Shown: 1. Copper bearing bushing, 2. Clamp body, 3. Set screw, 4. Ring body, 5. Fixing body, 6. Fastening workpiece screw hole, 7. 180° positioning marking line, 8. Fastening fixture screw, 9, lathe tool holder, 10, auxiliary positioning support tool, 11, lathe tailstock, 12, Morse taper hole, 13, tool bar hole, 14, lubricating oil hole, 15, tool bar, 16, Three-jaw chuck, 17, blade, 18, the first oil groove.

[0023] A method for processing the oil groove in the inner hole of the copper bearing bush of the present invention adopts the following process steps:

[0024] (1) First put the copper bearing bush 1 into the clamp body 2, and after the end faces are aligned, lock it with two set screws 3. The clamp body 2 is an integral structure, see Figure 7 , Figure 8 As shown, the clamp body 2 includes a ring body 4 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com