Preparation method of copper foil antenna

A copper foil and antenna technology, applied in the field of copper foil antenna preparation, can solve the problems of high product rejection rate, unstable working pressure, short tool life, etc., and achieve the effect of comprehensive cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

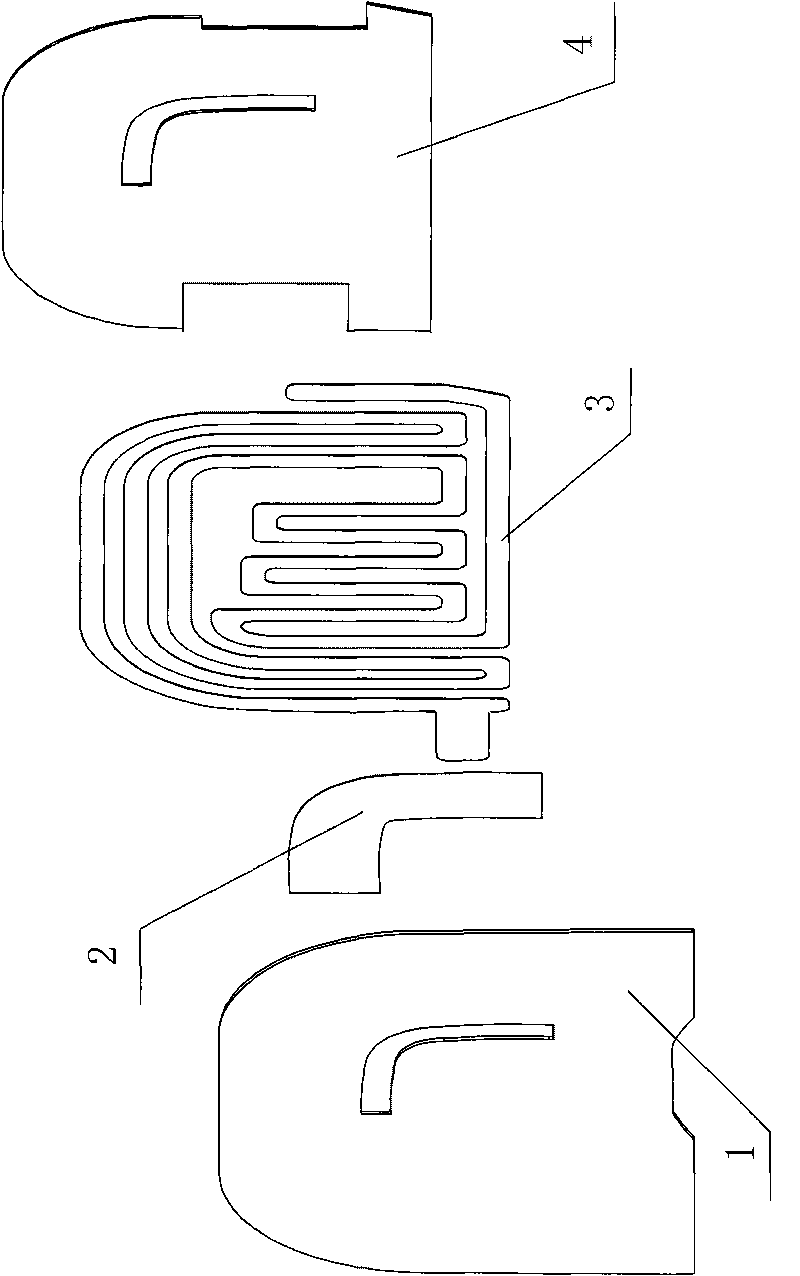

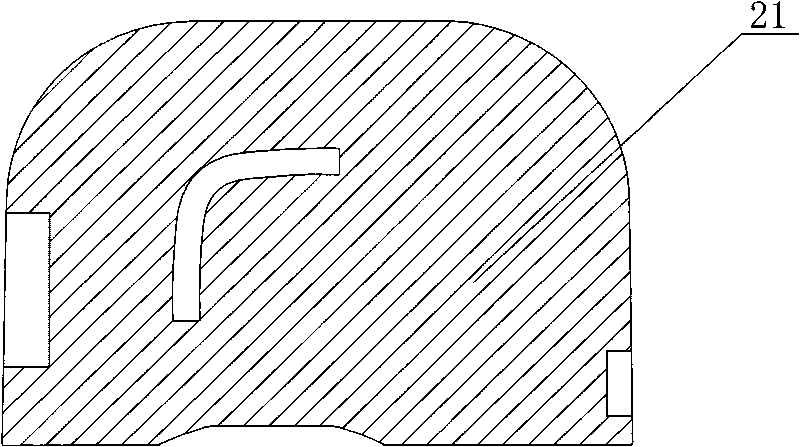

[0072] refer to figure 1 As shown, the method of the embodiment of the present invention is mainly to provide copper foil antennas for users (manufacturers of mobile phones, or customers using copper foil antennas, etc.). For the convenience of packaging, storage and transportation, the structural design of the products produced by the present invention is Four layers: black PC layer 21, mesh layer 22, copper foil layer 23 and transparent PET layer 24 in sequence.

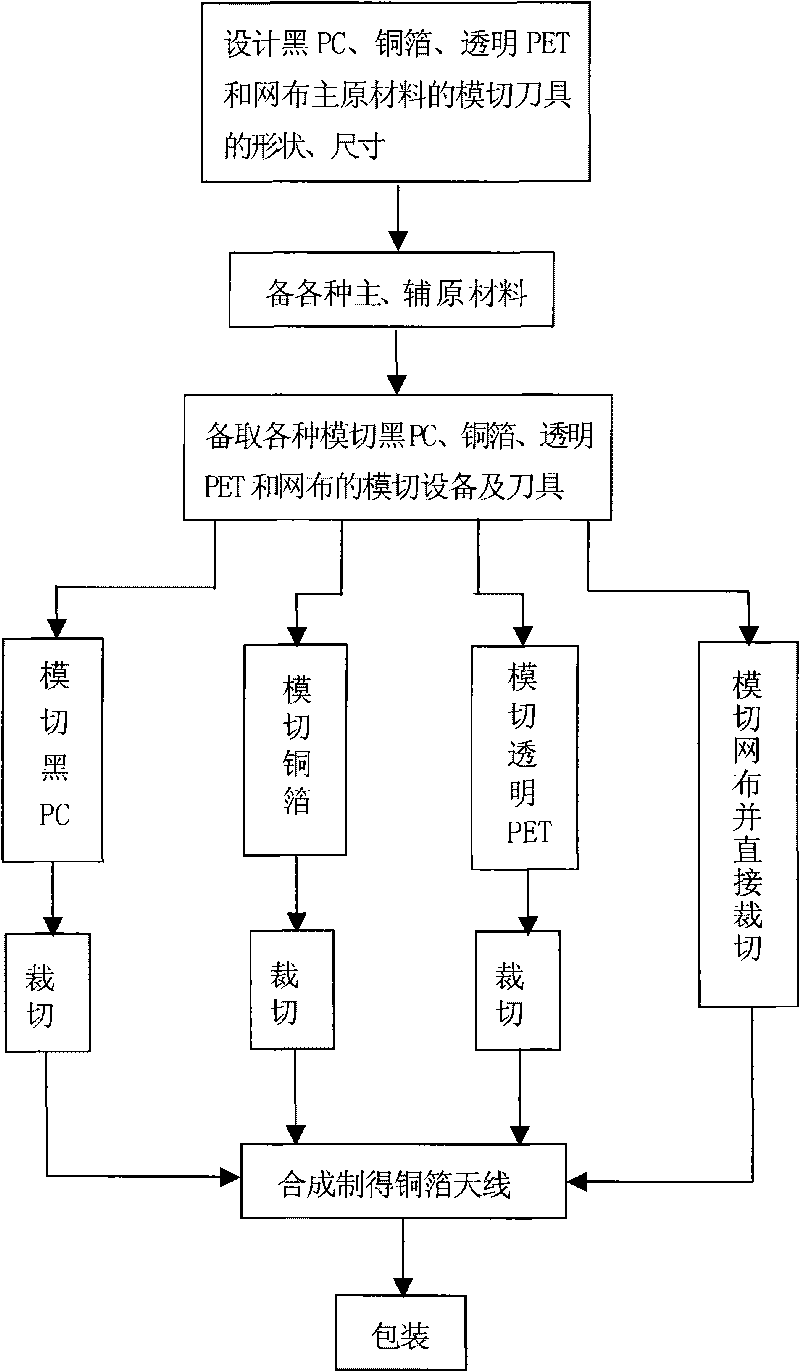

[0073] refer to figure 2 Shown, the die-cutting method of die-cut copper foil antenna of the present invention is:

[0074] 1. Basic design:

[0075] Design the shape and size of the die-cutting tool for the main raw materials of black PC, copper foil, transparent PET and mesh according to the requirements of the die-cut copper foil antenna;

[0076] Second, prepare raw materials:

[0077] Firstly prepare double-sided adhesive tape, PET, copper foil, black PC, transparent PET, mesh cloth, protective film and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com