Milk beverage and preparation method thereof

A technology of beverage and slurry, which is applied in the field of milk beverage and its production, can solve the problems of single taste of plant protein milk beverage, heavy beany flavor of soybean, and single protein source, so as to enhance the physical fitness of Chinese people, optimize the taste and Sensation, the effect of improving the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

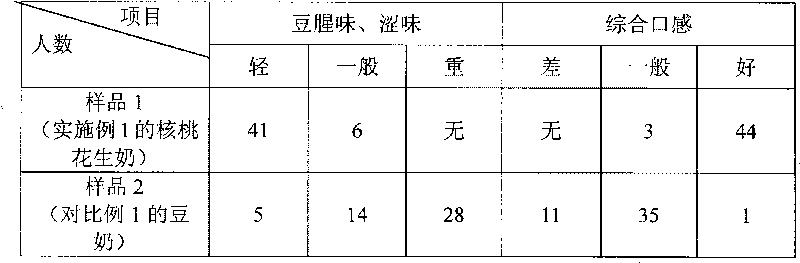

Examples

Embodiment 1

[0031] Preparation of Walnut Peanut Milk:

[0032] a. Selection: Weigh 4.5 kg of peanuts, 4.5 kg of soybeans, and 1 kg of walnuts, and remove impurities, mildew, and moth-eaten parts in peanuts, soybeans, and walnuts.

[0033] b. Roasting and peeling: Roast and peel peanuts and soybeans with a roasting machine and peeling machine; the baking temperature is 160°C.

[0034] c. Enzyme-inactivating pulping: the above-mentioned roasted and peeled soybean, peanut and walnut mixed material is first subjected to 120°C steam for 5 seconds to inactivate the enzyme, and then mixed with 90°C, pH 7.5, and the mass of the above-mentioned mixed material 8 to 9 times the sodium bicarbonate aqueous solution with a mass percentage concentration of 0.5‰ is mixed, and finally enters the colloid mill for refining, so that the protein and other nutrients in the above materials are fully separated.

[0035] d. Deodorization and sterilization: heat the slurry after pulping to 120°C to 180°C and then...

Embodiment 2-10

[0039] Embodiment 2-10: according to the type, quality and process parameters of the substances in Table 1 and Table 2 below, the others are the same as in Embodiment 1. The walnut peanut milk beverage of the present invention is prepared.

[0040] Table 1

[0041] Reality

apply

example

peanuts, soybeans,

quality of walnuts

(Unit: kg)

bake

temperature

(℃)

steam

Enzyme inactivation

temperature

(℃)

degree(℃)

Liquid pH

value

sodium bicarbonate

Concentrated

Spend

walnut blossom

raw protein

pulp quality

Quantity (single

bit: male

catty)

milk quality

Quantity (single

bit: public

catty)

water (single

bit: male

catty)

emulsifier

Quantitative

Q...

Embodiment 11

[0045]250g white fungus is boiled into 10 kilograms of white fungus pulp for subsequent use, 40 kilograms of walnut peanut protein slurry such as embodiment 1, 62.5 kilograms of milk, 11.75 kilograms of white granulated sugar, 0.6 kilograms of glyceryl monostearate and 0.15 kilograms of microcrystalline cellulose are mixed, after Homogenize at 15-20Mpa, sterilize at 120-130°C for 7s, pack, and make tremella walnut and peanut milk beverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com