Alprostadil liposome microsphere preparation

A technology of lipid microspheres and dill fat, which is applied in the field of pharmaceutical preparations and can solve the problems of short validity period and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

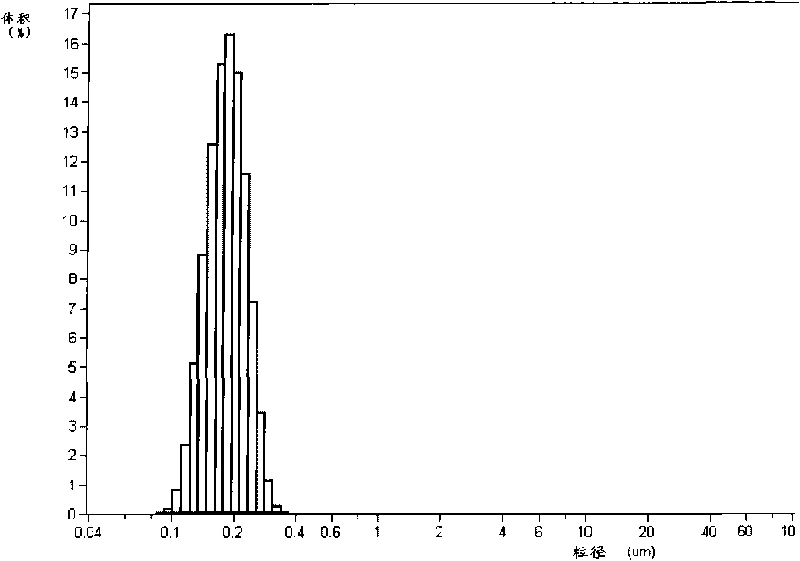

[0040]Preheat 80g of soybean oil for injection to 60-70°C, add 20g of refined soybean lecithin, 1g of stabilizer (mass ratio is oleic acid: coenzyme Q10 = 1:1), stir with hand to form a uniform oil phase, then slowly add 7mg of prostaglandin Dil raw material, stir at 60-70°C at high speed (8000 rpm) for 3 minutes to make it evenly dissolve in the oil phase; dilute 20g of glycerin for injection with an appropriate amount of water for injection preheated to 60-70°C Finally, a uniform water phase is formed; the above water phase is poured into the mixer, and the oil phase is slowly dropped into the water phase under the stirring condition of 10000 rpm, stirred for 10 minutes, and milky white colostrum is formed after uniform dispersion; Add the colostrum to the water for injection preheated to 60-70°C to reach the full amount, transfer it to a high-pressure homogenizer, homogenize it for 5-8 times under the pressure of 5000-15000Psi, take samples to measure the particle size until...

Embodiment 2

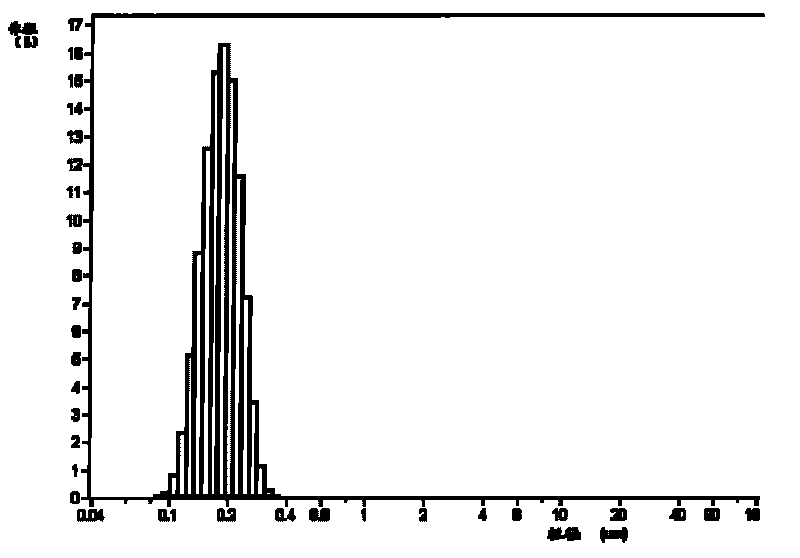

[0042] Preheat 100g of soybean oil for injection to 60-70°C, add 25g of refined soybean lecithin, 1.5g of stabilizer (mass ratio: cholesterol:vitamin E=1:1), stir with hand to form a uniform oil phase, then slowly add 7mg of prostaglandin Dil raw material, stir at 60-70°C at high speed (8000 rpm) for 3 minutes to make it evenly dissolve in the oil phase; dilute 20g of glycerin for injection with an appropriate amount of water for injection preheated to 60-70°C Finally, a uniform water phase is formed; the above water phase is poured into the mixer, and the oil phase is slowly dropped into the water phase under the stirring condition of 10000 rpm, stirred for 10 minutes, and milky white colostrum is formed after uniform dispersion; Add the colostrum to the water for injection preheated to 60-70°C to reach the full amount, transfer it to a high-pressure homogenizer, homogenize it for 5-8 times under the pressure of 5000-15000Psi, take samples to measure the particle size until th...

Embodiment 3

[0044] 100g soybean oil for injection is preheated to 60~70 ℃, adds the mixture (mass ratio of 5: 1) of 20g refined lecithin and polyoxyethylene castor oil, 2g stabilizer (mass ratio is sodium oleate: Vitamin C = 1: 1), after hand-held stirring to form a uniform oil phase, slowly add 15 mg of alprostadil bulk drug, and stir at a high speed (8000 rpm) at 60 to 70 ° C for 3 minutes to make it evenly dissolve in the oil phase; Glycerin for injection is diluted with an appropriate amount of water for injection preheated to 60-70°C to form a uniform water phase; pour the above water phase into the mixer, and slowly drop the oil phase into the In the water phase, stir for 10 minutes to form milky white colostrum after uniform dispersion; add the colostrum to the water for injection preheated to 60-70°C to reach the full amount, transfer it to a high-pressure homogenizer, and place it under a pressure of 5000-15000Psi Homogenize 5 to 8 times, take samples to measure the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com