Kiln slag processing technology of zinc volatilizing kiln

A processing technology, zinc volatilization technology, applied in the field of zinc volatilization kiln slag processing technology, can solve the problems of waste of water resources, environmental secondary pollution, energy consumption, etc., achieve recovery rate improvement, ensure magnetic separation grade, dissociation degree Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

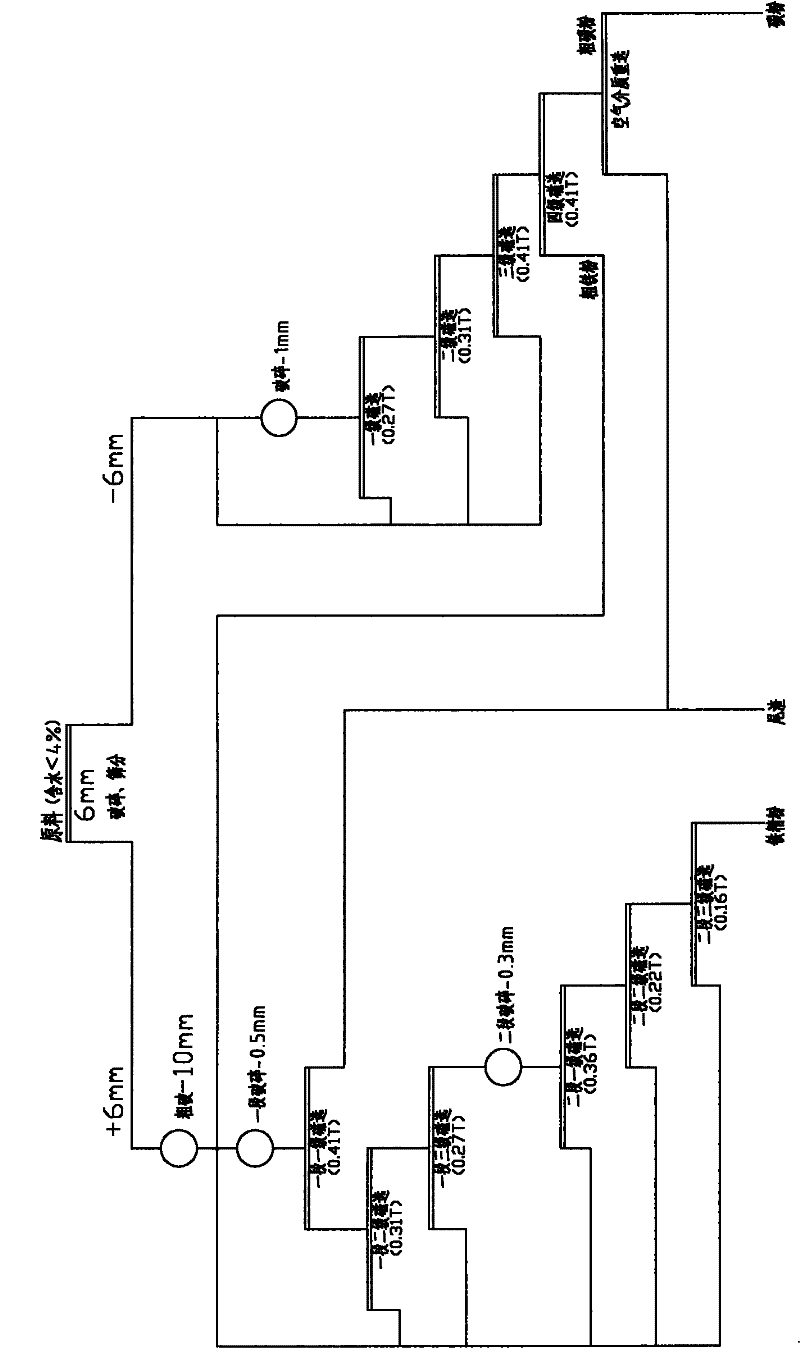

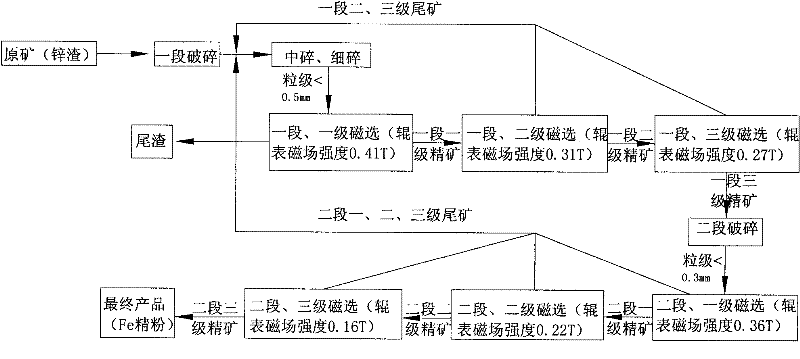

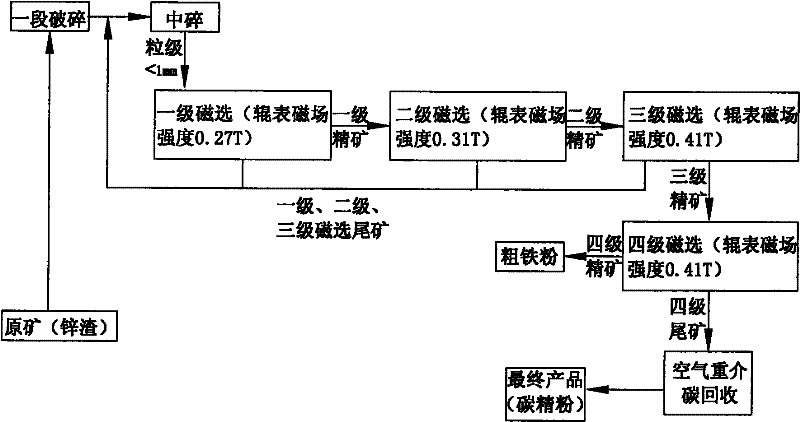

[0026] Such as figure 1 Shown, the method of the present invention comprises coarse crushing-pre-screening process step, intermediate crushing-fine crushing process step, two-section three-stage magnetic separation Fe fine powder process step (see figure 2 ), four-stage magnetic separation and air medium re-election carbon fine powder process steps (see image 3 );

[0027] The coarse crushing-pre-screening process steps include: a, crushing the zinc volatilization kiln slag with a large particle size and a water content of ≤4% through a four-roller counter-pole crusher to a particle size of 6mm for screening; b, crushing the slag ≥ The 6mm screened material is crushed twice before entering the first stage of the third-stage magnetic separation; c. The ≤6mm screened material is crushed once before entering the fourth-stage magnetic separation process; the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com