Inorganic crystal whisker modified synergic polyimide/epoxy blend and preparation method thereof

A polyimide siloxane, synergistic modification technology, applied in the field of polyimide/epoxy blends, can solve the problems of limited application, brittleness, poor impact resistance and stress crack resistance, and achieve Effect of improving strength and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Formula: (parts by weight)

[0032] 100 parts epoxy resin

[0033] Methyltetrahydrophthalic anhydride 80 parts

[0034] N,N-Dimethylbenzylamine 0.1 parts

[0035] 3 parts calcium sulfate whiskers

[0036] Epoxy resin preferably adopts the epoxy resin that average epoxy equivalent is 171g / eq;

[0037] The average length of the calcium sulfate whiskers is 100 (μm), and the average diameter is 5 (μm);

[0038] Preparation:

[0039] Mix the epoxy resin and calcium sulfate whiskers, stir mechanically at a speed of 500 rpm for 5 minutes, and disperse;

[0040] Then at 130°C, add curing agents methyltetrahydrophthalic anhydride and N,N-dimethylbenzylamine, stir mechanically for 3 minutes, pour into the mold, put it into a 150°C oven for curing for 6 hours, and then post-cure at 180°C for 3 minutes. Hours, demoulding to obtain inorganic calcium sulfate whisker modified epoxy resin.

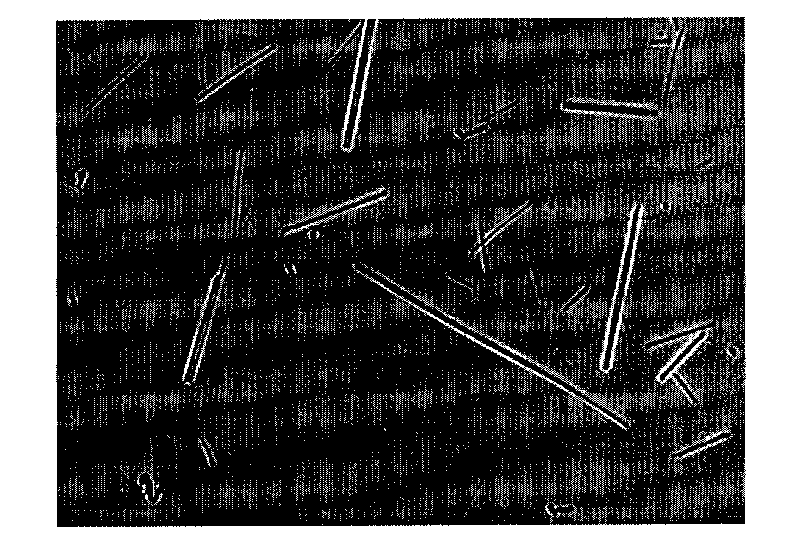

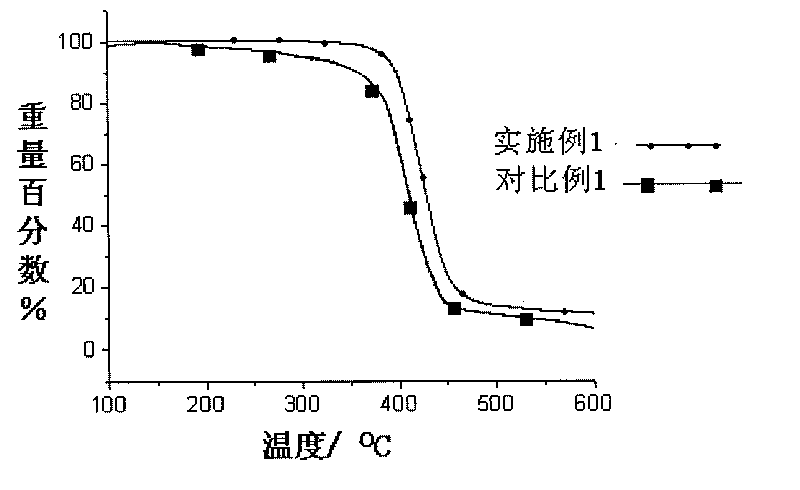

[0041] Electron microscope photos such as figure 1 . Thermogravimetric analysis curve ...

Embodiment 2

[0043] formula:

[0044] 100 parts epoxy resin

[0045] Polyimide siloxane 30 parts

[0046] Methyltetrahydrophthalic anhydride 80 parts

[0047] N,N-Dimethylbenzylamine 0.3 parts

[0048] Calcium Sulfate Whiskers 5 parts

[0049] Epoxy resin preferably adopts the epoxy resin that average epoxy equivalent is 171g / eq;

[0050] The average length of the calcium sulfate whiskers is 80 (μm), and the average diameter is 5 (μm);

[0051] Preparation:

[0052] Add epoxy resin to 30g polyimide siloxane and heat to dissolve at 180°C;

[0053] Add calcium sulfate whiskers, stir mechanically at a speed of 500 rpm for 10 minutes, and disperse;

[0054] At 130°C, add curing agents methyltetrahydrophthalic anhydride and N,N-dimethylbenzylamine, stir mechanically for 2 minutes, pour into the mold, put in an oven at 150°C for 5 hours, and then post-cure at 200°C for 2 hours. Release the mold to obtain a polyimide / epoxy blend modified by inorganic calcium sulfate whiskers.

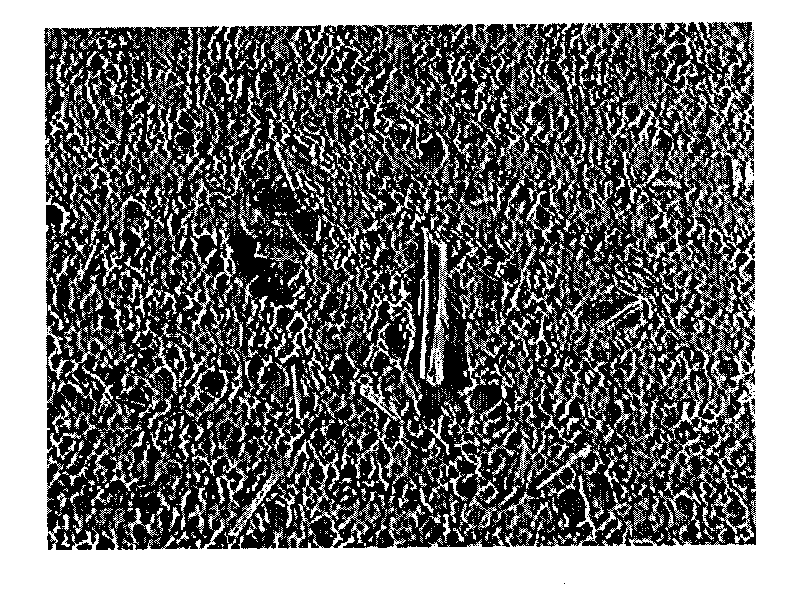

[0055] mi...

Embodiment 3

[0057] Recipe: (weight)

[0058] 100 parts epoxy resin

[0059] Polyimide siloxane 25 parts

[0060] Methyltetrahydrophthalic anhydride 85 parts

[0061] N,N-Dimethylbenzylamine 0.3 parts

[0062] 3 parts calcium sulfate whiskers

[0063] Epoxy resin preferably adopts the epoxy resin that average epoxy equivalent is 171g / eq;

[0064] The average length of the calcium sulfate whiskers is 50 (μm), and the average diameter is 15 (μm);

[0065] Preparation:

[0066] Add epoxy resin to polyimide siloxane, heat and dissolve at 180°C; add calcium sulfate whiskers, mechanically stir at 500 rpm for 10 minutes, and disperse;

[0067] At 130°C, add curing agents methyltetrahydrophthalic anhydride and N,N-dimethylbenzylamine, stir mechanically for 2 minutes, pour into the mold, put in a 150°C oven for curing for 6 hours, and then post-cure for 3 hours at 190°C. An inorganic calcium sulfate whisker-modified polyimide / epoxy blend was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com