Doping method and doping device of pulling reincorporation antimony crystals

A heavy-doping and Czochralski technology, applied in the direction of single crystal growth, chemical instruments and methods, self-melt pulling method, etc., can solve the problems of not reaching the resistivity range, affecting the crystal formation rate, and low doping efficiency. , to achieve the effects of stable and controllable reaction, improved crystallization rate and short doping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

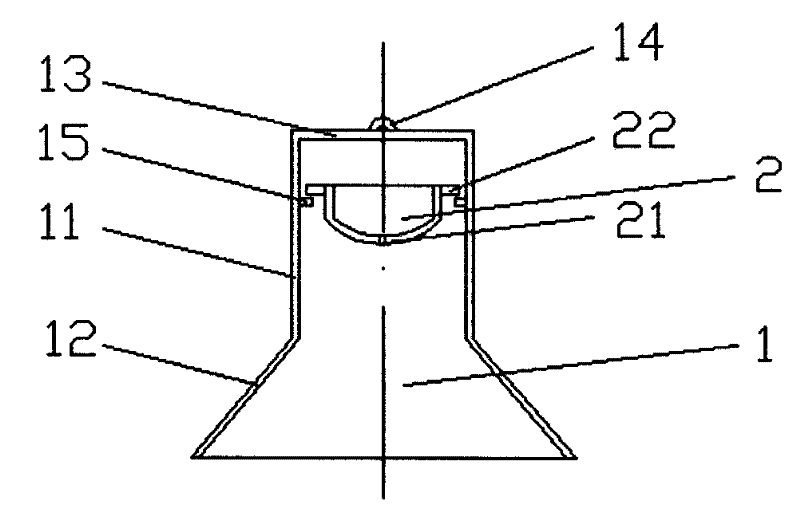

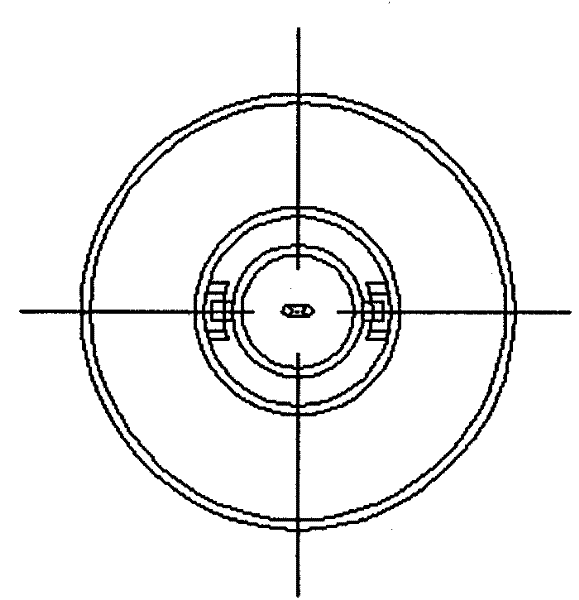

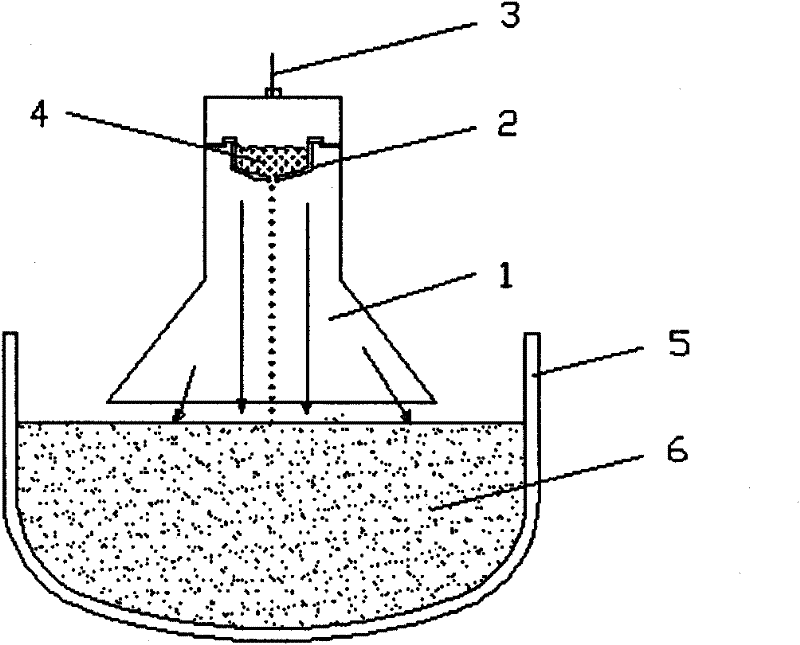

[0026] The doping device designed in the present invention includes a quartz cover 1 and a small quartz crucible 2, the small quartz crucible 2 is suspended and fixed in the quartz cover 1, and a small hole 21 is provided at the bottom of the small quartz crucible 2. The diameter of the small hole 21 at the bottom is set to 5±0.2mm. The quartz cover 1 comprises a straight cylinder 11, a trumpet-shaped cover 12, and a cover 13, and the top of the cover 13 is provided with a suspension ring 14 for suspension. The inner wall of the straight cylinder 11 is provided with two positioning grooves 15 for hanging and fixing the small quartz crucible 2, and the crucible edge of the small quartz crucible 2 is provided with an outer edge 22 which is fixedly matched with the two positioning grooves 15, such as figure 1 , 2 shown.

[0027] The straight cylinder 11 and the trumpet-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com