System for quickly measuring surface quality

A surface quality and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of relatively high anti-interference ability of the measurement system, achieve the effect of low cost and increase the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

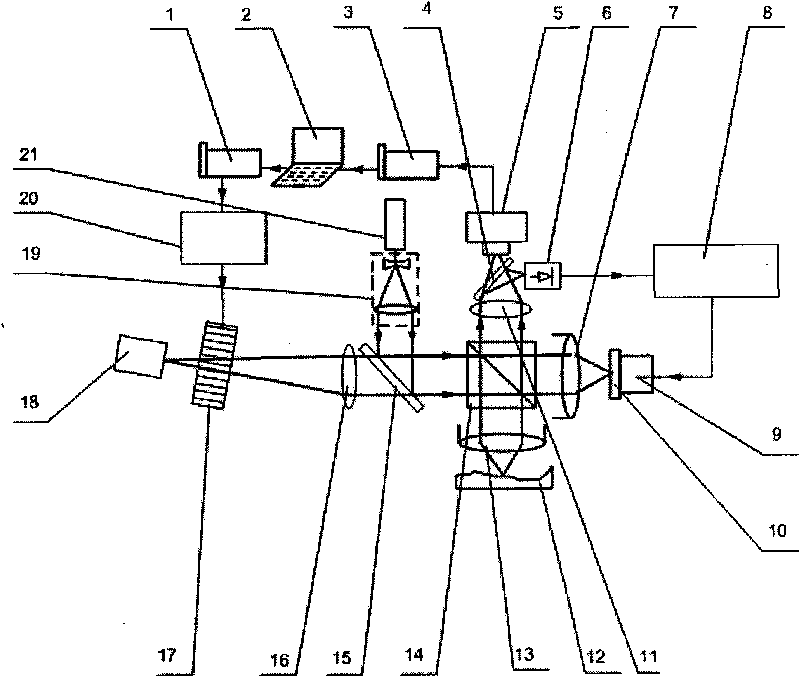

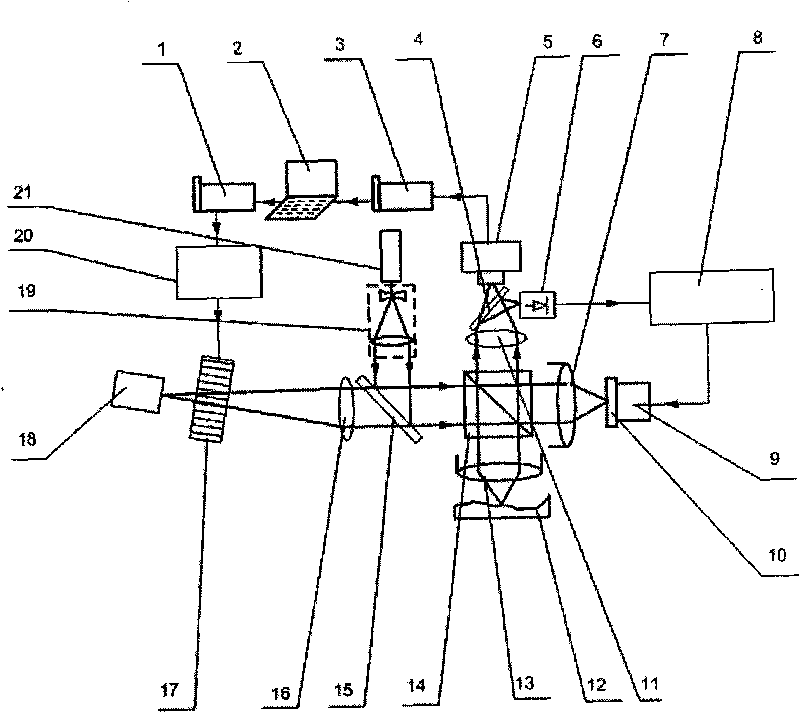

[0019] As shown in the drawings, the present invention comprises two sets of interferometers coupled together, wherein:

[0020] 1) A set of main interferometer for measurement: including data acquisition card 1, computer 2, image acquisition card 3, three beam splitters 4, 14, 15, camera 5, two objective lenses 7, 13, reference mirror 10, imaging Lens 11, collimating mirror 16, tunable optical filter 17, white light source 18 and optical filter driving unit 20; the incident light emitted by white light source 18 becomes parallel light after passing through tunable optical filter 17 and collimating mirror 16 1. After passing through the first beam splitter 15 to the second beam splitter 14, the incident light is divided into two paths, one path of light is incident on the reference mirror 10 through the first objective lens 7, and the other path is incident on the measured sample 12 through the second objective lens 13 surface, the light incident on the surface of the referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com