CAM system for automobile longeron punching processing and control method and construction method thereof

A technology of an automobile longitudinal beam and a control method, which is applied in the field of automobile longitudinal beam CAM system and control, can solve the problems of backward control, cumbersomeness and high error rate of the punching CAM system, and achieves faster production tact, higher punching speed, and redundancy. small time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

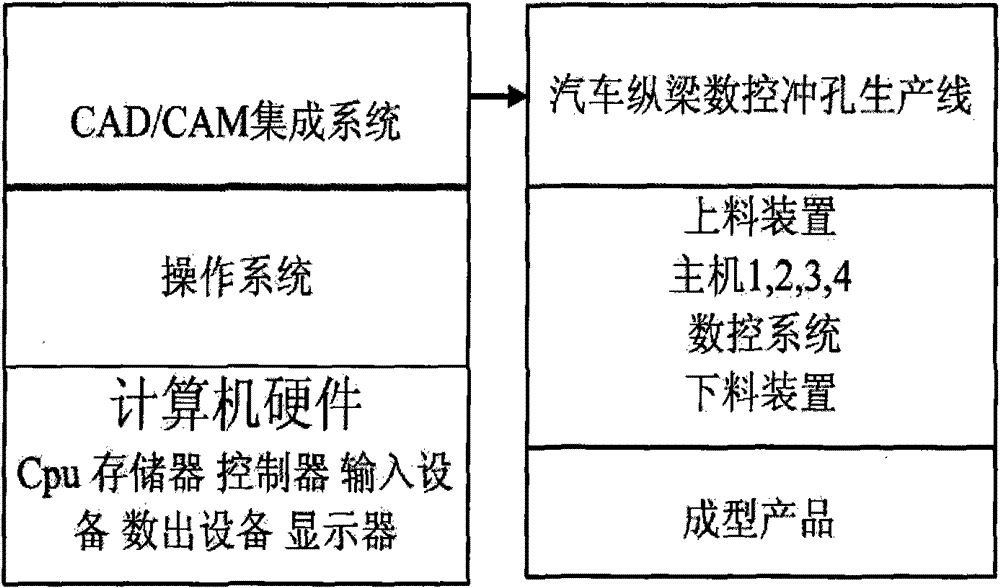

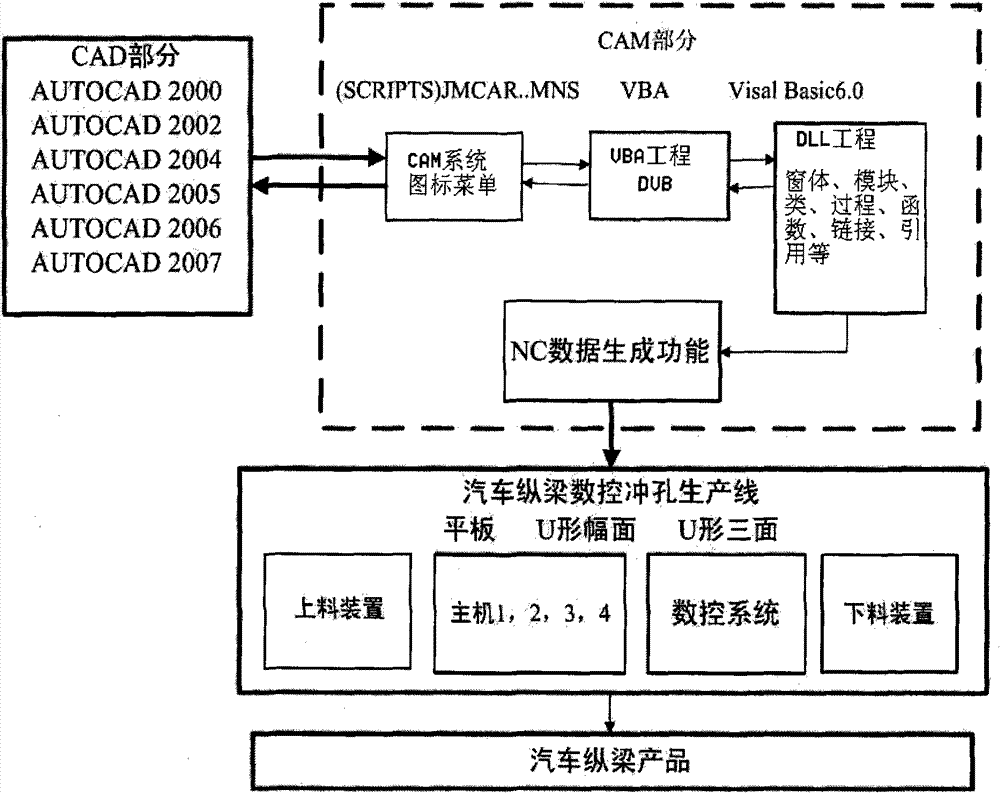

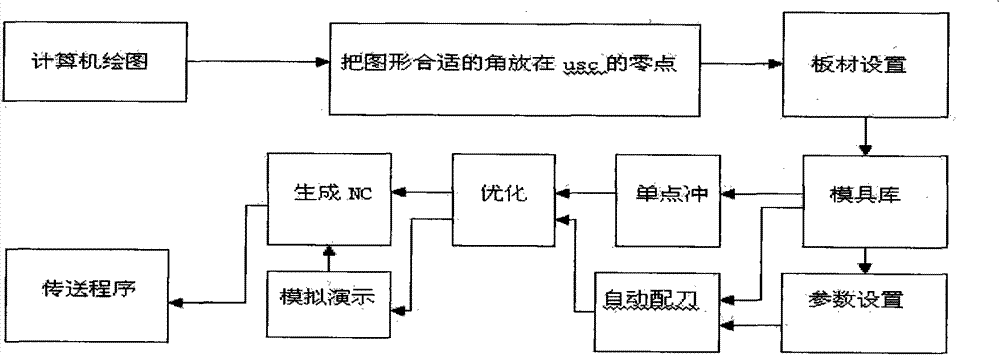

[0059] A CAM system for the punching process of the longitudinal beam of the automobile is characterized in that it includes:

[0060] 1. A device for reading CAD files.

[0061] Including computer hardware and operating system, CAD system, module for deleting duplicates, module for obtaining CAD data, module for screening and separating data and data storage module.

[0062] 2. A device for establishing links, icon menus and interfaces in the CAD / CAM system.

[0063] Including ActiveX Automation technology, visual Basic main program, VBA link program, scripts (Scripts), icon menu database and SETUP installation program.

[0064] 3. A device that converts the data in the CAD file into the mold model and dimension data of the CAM system.

[0065] Including mold database, plate setting module, tolerance setting module, data storage module and CAM generation module.

[0066] 4. Mold adaptation, optimization and simulation operation device.

[0067] It includes a dead zone jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com