Palladium loaded chelate resin and preparation method thereof

A chelating resin and palladium-loading technology are applied in the field of preparation of the above-mentioned palladium-loading chelating resin, and can solve problems such as difficulty in synthesizing monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

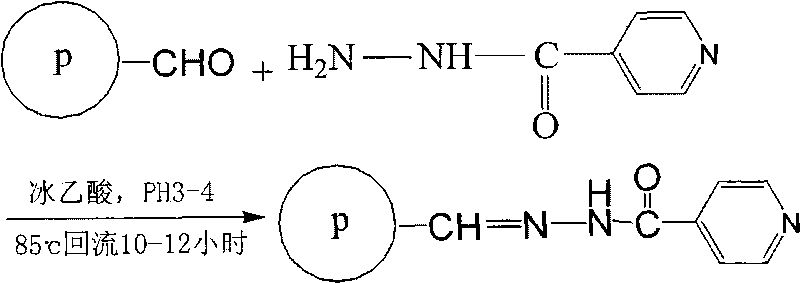

Method used

Image

Examples

preparation example Construction

[0045] During the preparation of the two resins, the filtrate was collected, and the palladium content in the filtrate was measured on ICP-OES. The results show that almost all palladium is loaded on the resin within the experimental concentration range, and the palladium loading rate can reach more than 99.5%. As for the process of preparing resin 2 from resin 1 through potassium borohydride reduction, there was no palladium elution, indicating that the reduction of palladium by potassium borohydride was performed in situ on the resin, and the palladium content in the two resins was equivalent.

[0046] In addition, the loading process of palladium and resin is a chemical bonding process, and palladium is highly dispersed on the resin, and the ratio of palladium to resin is 2.5-15mgPd / g resin under the experimental conditions, palladium can be completely loaded on the resin. Use KBH 4 Reduce resin 1, palladium cannot be eluted. Palladium-polyacrylaldehyde-isonicotinylhydrazone ...

Embodiment 1

[0048] Weigh 4g polyacrylaldehyde isonicotinoyl hydrazone resin, soak it in 0.1mol / L hydrochloric acid for 0.5 hours to swell it, and then add 10mL of 1mg / mL palladium standard solution (palladium loading is 2.5mgPd / g resin), Stir on a magnetic stirrer for about 2 hours. The reacted resin is filtered, collected, and dried naturally to obtain Resin 1. Palladium loading rates are all above 99.5%.

[0049] Take 2g of resin 1, soak it in 0.1mol / L hydrochloric acid for 0.5 hours to swell it, and add 100mL of KBH with a concentration of 0.1mol / L dropwise 4 , The dripping is completed within 1 hour, and then stirred on the electromagnetic stirrer for 2 hours. The reacted resin is filtered and collected to obtain the zero-valent state palladium-carrying resin product of resin 1 (resin 2). During the reduction conversion process, no palladium dissolution was detected in the solution, so the palladium loading rate on the resin was still above 99.5%.

Embodiment 2

[0051] Weigh 2g of polyacrylaldehyde isonicotinic hydrazone resin, soak it in 0.1mol / L hydrochloric acid for 0.5 hours to swell it, then add 30mL of 1mg / mL palladium standard solution (palladium loading is 15mgPd / g resin), Stir on a magnetic stirrer for about 3 hours. The reacted resin is filtered, collected, and dried naturally to obtain Resin 1. Palladium loading rates are all above 99.5%.

[0052] Take 1g of resin 1, soak it in 0.1mol / L hydrochloric acid for 0.5 hours to swell it, and add 100mL of KBH with a concentration of 0.1mol / L dropwise 4 , The dripping is completed within 1 hour, and then stirred on the electromagnetic stirrer for 3 hours. The reacted resin is filtered and collected to obtain the zero-valent state palladium-carrying chelating resin product of resin 1 (resin 2). During the reduction conversion process, no palladium dissolution was detected in the solution, so the palladium loading rate on the resin was still above 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com