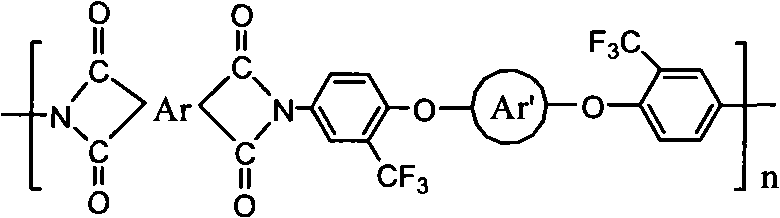

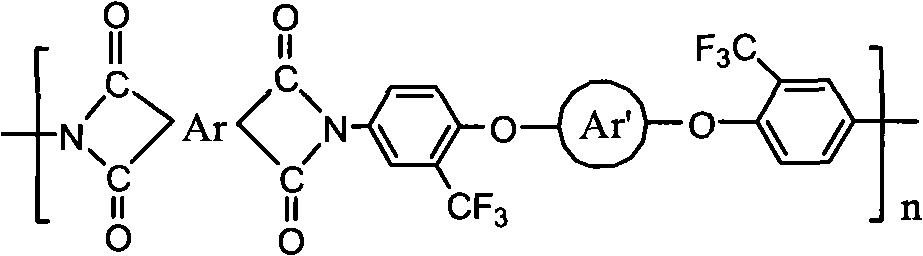

Polyimide film material capable of serving as flexible transparent conducting film substrate and preparation method thereof

A technology of transparent conductive film and polyimide film, which is applied to the conductive layer on the insulating carrier and other directions, can solve the problems of UV resistance, high moisture absorption rate, and inability to meet high temperature processing technology, so as to increase transparency and reduce moisture absorption. performance, excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

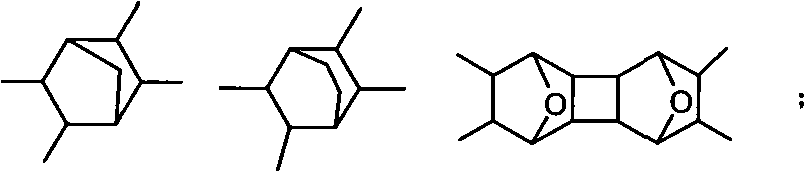

[0032]In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 6.5445 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (0.01mol) was dissolved in 51.38ml of DMAc solvent, stirred to make the solution clear and transparent. Then, 1.9611 g (0.01 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA) was added to the solution at one time, stirred to dissolve it completely, and continued to react for 15 to 25 minutes under a nitrogen protection environment. Hours, the obtained transparent viscous liquid is polyamic acid, a precursor of polyimide that can be used as a flexible transparent conductive film substrate, with a solid content of 15 wt % and an intrinsic viscosity of 1.25 dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr,...

Embodiment 2

[0035] In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 6.5445 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (0.01mol) was dissolved in 52.23ml of DMAc solvent, stirred to make the solution clear and transparent. Then add 2.1014g (0.01mol) of 1,2,4,5-cyclopentanetetracarboxylic dianhydride (CPDA) to the solution at one time, stir to dissolve it completely, and continue the reaction for 15 to 25 minutes under nitrogen protection. Hours, the obtained transparent viscous liquid is polyamic acid, a precursor of polyimide that can be used as a flexible transparent conductive film substrate, with a solid content of 15 wt % and an intrinsic viscosity of 1.06 dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr, 0.5hr at 300°C. Aft...

example 3

[0038] In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 6.5445 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (0.01mol) was dissolved in 53.08ml of DMAc solvent, stirred to make the solution clear and transparent. Then, 2.2417 g (0.01 mol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (CHDA) was added to the solution at one time, stirred to dissolve it completely, and continued to react for 15 to 25 minutes under a nitrogen protection environment. Hours, the obtained transparent viscous liquid is polyamic acid, a precursor of polyimide that can be used as a flexible transparent conductive film substrate, with a solid content of 15 wt % and an intrinsic viscosity of 1.00 dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com