Preparation method of modified aromatic hydrocarbon petroleum resin

An aromatic hydrocarbon petroleum resin and modification technology, applied in the field of petroleum resin, can solve the problems of complex molecular structure, high glass transition temperature, limited use range, etc., and achieve the effects of low fluorescence intensity, high aromaticity, and prevention of explosive polymer formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 4-MS and DVB at a mass ratio of 1:0.02 to obtain the ingredients, put 50% of the total mass of methylcyclohexane and 0.8% of boron trifluoride ether catalyst into the reactor with stirring, and fill it with N 2 protection, and then slowly add the ingredients dropwise at -20°C, the reaction time is 1h; after the dropwise addition is completed, the temperature is raised to 45°C, and MAH accounting for 0.2% of the total material mass is added, and the reaction is 20min to obtain a polymer resin liquid; the above polymer resin liquid is Wash with 15% sodium hydroxide lye, wash with water several times until neutral, and remove the catalyst; then rectify under reduced pressure to 240°C under vacuum degree -0.085MPa, remove solvent and oligomer, and obtain the softening point 101.5°C, Gardner color number 2.5#, Mw 940, aromaticity 44.6% modified aromatic petroleum resin.

Embodiment 2~4

[0027] Taking 4-MS and DVB as raw materials, under the same process conditions as in Example 1, changing the DVB content in the batching has the following effects on the performance of the modified aromatic petroleum resin:

[0028] DVB ratio Softening Point Color thermal stability mw Transmittance Aromaticity Example 2 0∶1 93.5℃ 2.1 6.0 875 75% 52.2 Example 3 0.03∶1 105.6℃ 2.3 5.5 1090 86% 42.8 Example 4 0.05∶1 114.0℃ 2.5 5.4 1240 90% 40.1

[0029] It can be seen from the above table that the softening point, color number, weight average molecular weight Mw and light transmittance of the modified aromatic petroleum resin all increase with the increase of the proportion of DVB in the ingredients, while the thermal stability gradually decreases. That is, DVB as a modifying component can increase the degree of internal crosslinking of resin molecules, increase the molecular weight and softening point, and improve the...

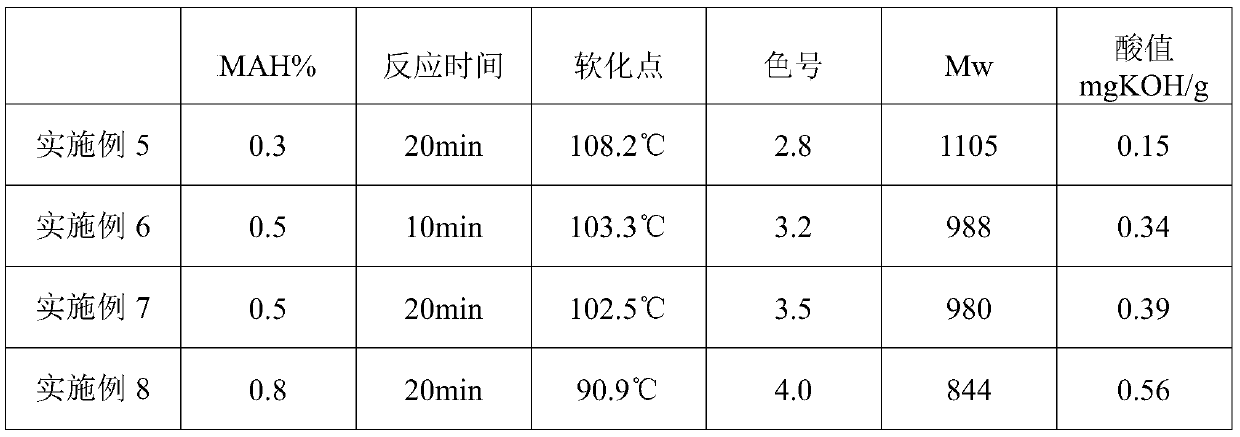

Embodiment 5~8

[0031]

[0032] In embodiment 5~8, all the other process conditions are identical with embodiment 1.

[0033] It can be seen from the above table that with the increase of MAH addition, the softening point and Mw of the modified aromatic petroleum resin will decrease significantly, and the acid value will increase accordingly, but at the same time, the color number of the resin will be significantly deteriorated. By adjusting the MAH reaction time, the performance of the modified aromatic petroleum resin is less affected, and the color number and acid value of the resin are only slightly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com