Self-protected flux-cored wire

A flux-cored wire, self-protection technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of expensive price, limited application scope, etc., and achieve low price, wide application prospects, and high cost performance of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0033] The drug core components are calculated by mass percentage as:

[0034] Graphite: 0.4%, metal manganese: 40%, metal chromium: 28%, metal nickel: 5%, metal molybdenum: 5%, heavy rare earth ferrosilicon: 2%, vanadium iron: 3%, niobium iron: 5.6%, metal Cobalt: 0%, Minerals: 20%.

[0035] The steel strip is 0.3×14, and the ratio is 48%, to make a Φ2.8 self-shielded flux cored wire.

[0036] There are five layers of surfacing welding, and samples are taken on the surfacing welding surface for chemical analysis. The chemical composition of the surfacing welding deposited metal is shown in Table 2:

[0037] Table 2

[0038] Alloy element

specific Embodiment 3

[0039] The drug core components are calculated by mass percentage as:

[0040] Graphite: 0.4%, manganese metal: 33%, chromium metal: 31%, nickel metal: 3%, molybdenum metal: 1.6%, heavy rare earth ferrosilicon: 2%, ferrovanadium: 9%, ferroniobium: 0%, metal Cobalt: 0%, Minerals: 20%.

[0041] The steel strip is 0.3×14, and the ratio is 48%, to make a Φ2.8 self-shielded flux cored wire.

[0042] There are five layers of surfacing welding, and samples are taken on the surfacing welding surface for chemical analysis. The chemical composition of the surfacing welding deposited metal is shown in Table 3:

[0043] table 3

[0044] alloy element

Embodiment 1

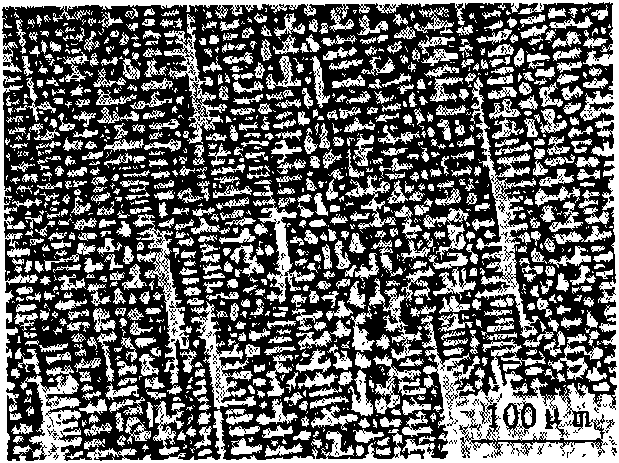

[0045] In embodiment 1, metallographic structure such as figure 2 As shown, the organization should obtain dispersed carbide particles on its austenite matrix during water cooling, which is conducive to uniform deformation and welding stress release. During use, under the action of pressure and impact, the surface layer continuously produces work hardening, that is, austenite transforms into induced martensite, forming a wear-resistant structure with inner toughness and outer hardness. The mechanical properties are shown in Table 4:

[0046] Table 4 Mechanical properties of surfacing deposited metal

[0047] σ b (MP)

[0048] Deposited metal has a large yield strength ratio and toughness, low yield strength is conducive to welding stress release, good impact toughness is conducive to material deformation, and reduces surfacing stress and crack tendency. After one layer of surfacing, there are longitudinal and transverse cracks on the surfacing surface. After two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com