Synthesis method and device for gas phase white carbon black

A technology of fumed white carbon black and synthesis equipment, applied in the direction of energy input, silicon oxide, etc., can solve problems such as unstable quality, small cooling capacity, and affecting product quality, so as to achieve stable product quality, increase production capacity, and make full use of heat energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

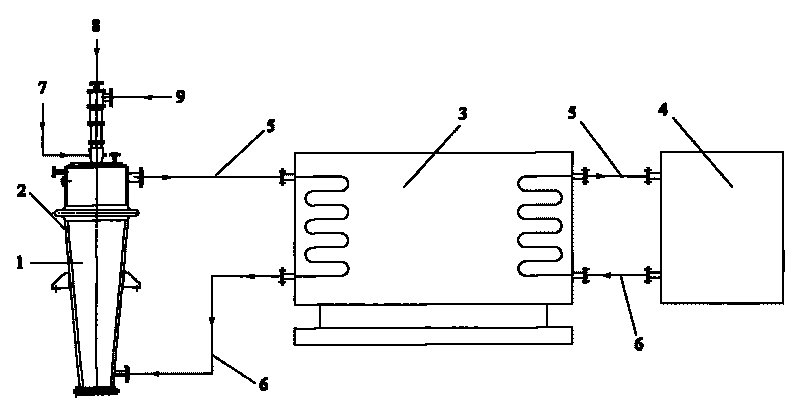

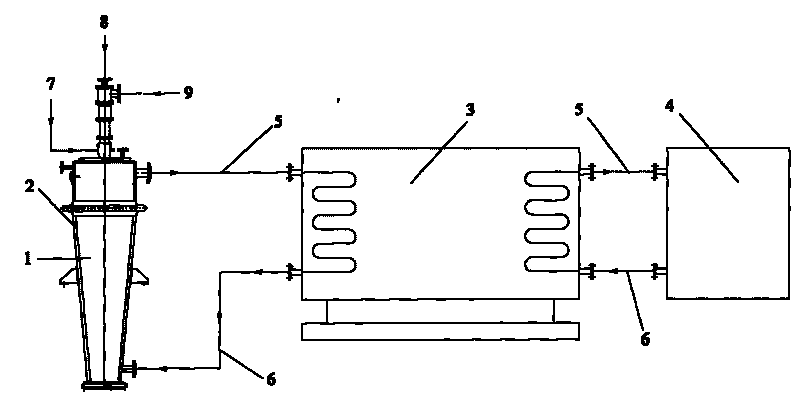

[0017] A kind of synthesis device of fumed white carbon black, its structure is as figure 1 As shown, the device is composed of a combustion furnace 1, a lithium bromide unit 2 and a refrigerated hydrochloric acid circulation system 3. The combustion furnace 1 is equipped with an electronic automatic ignition device, and a water-cooled jacket is installed on the outside. The furnace body of the combustion furnace is made of titanium-steel composite Materials, the water-cooled jacket material is carbon steel, the combustion furnace 1 is heated by hydrogen, and the water-cooled jacket is heated by natural gas. The upper part of the combustion furnace 1 is connected to the lithium bromide unit 2 through the return pipe 5, and the lower part is connected to the lithium bromide unit 2 through the upper water pipe 6. The water-cooled jacket sends the reaction heat of the combustion furnace 1 to the lithium bromide unit 2 through the return pipe 5, and drives the lithium bromide unit ...

Embodiment 2

[0020] A synthesis device for gas-phase white carbon black. The device is composed of a combustion furnace, a lithium bromide unit and a refrigerated hydrochloric acid circulation system. The combustion furnace is equipped with an electronic automatic ignition device, and a water-cooled jacket is provided outside. The furnace body of the combustion furnace is made of titanium -Steel composite material, the water-cooled jacket material is carbon steel, the combustion furnace is heated by hydrogen, the water-cooled jacket is heated by natural gas, the upper part of the combustion furnace is connected to the lithium bromide unit through the return pipe, and the lower part is connected to the lithium bromide unit through the upper water pipe. The reaction heat of the combustion furnace is sent to the lithium bromide unit through the return pipe, and the lithium bromide unit is driven to cool. The chilled water is sent to the chilled hydrochloric acid circulation system for tail gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com