Silica granules prepared on basis of pyrolysis and preparation method and app {} lication thereof

A technology of silica and particles, which is applied in the field of silica particles prepared by pyrolysis and its preparation and application, which can solve the problems of reducing the production capacity of polymerization reaction equipment, increasing wear and tear, and increasing catalyst loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

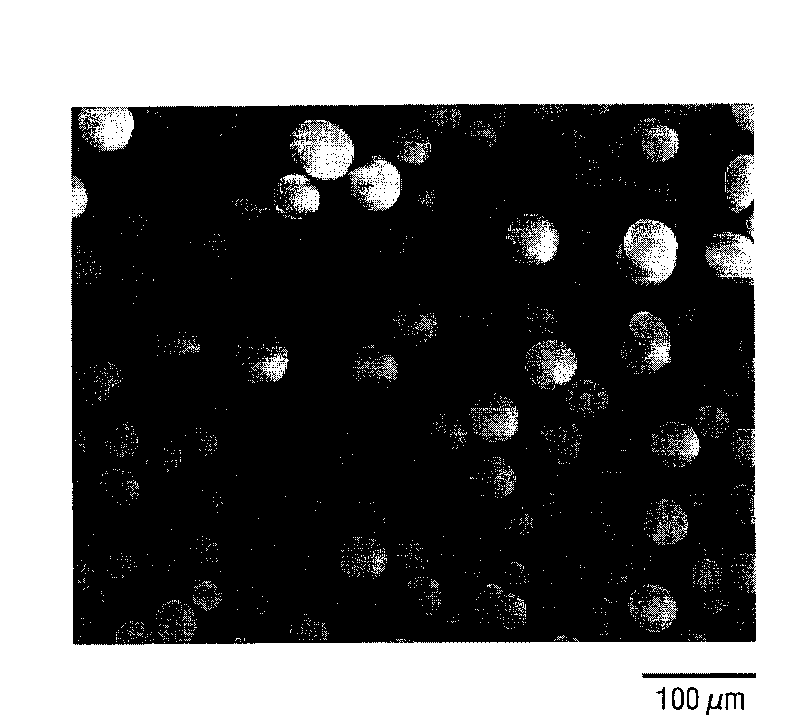

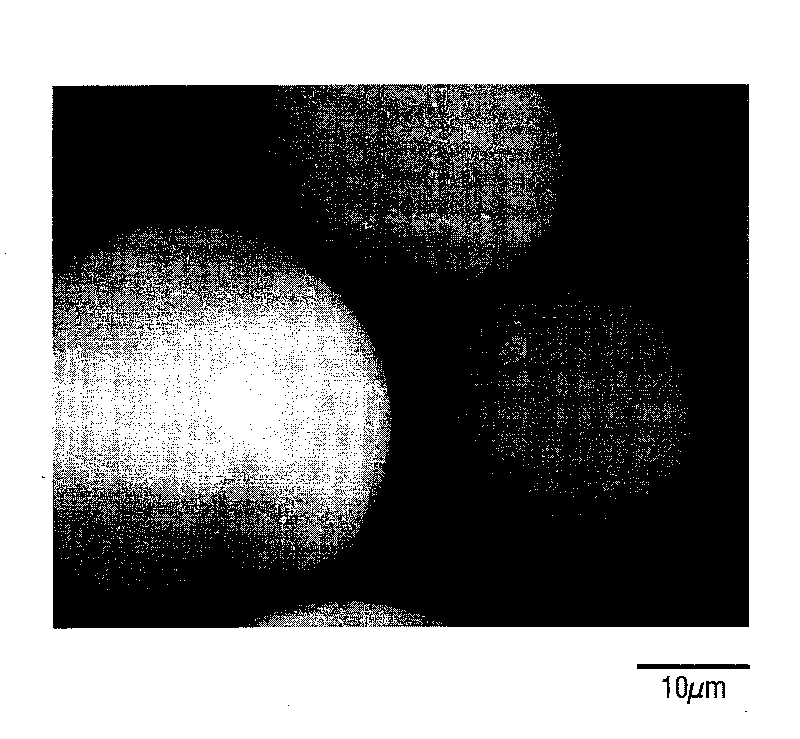

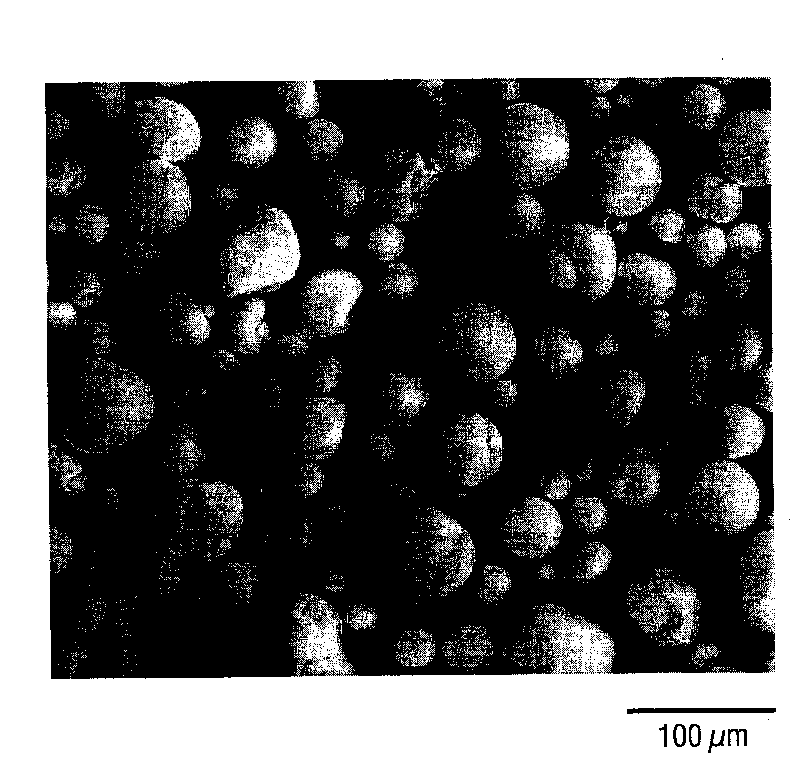

Image

Examples

Embodiment

[0137] As pyrogenically prepared silica, silica having the following physicochemical property data was used:

[0138] Table 1

[0139]

[0140]

[0141] 1) According to DIN 66131

[0142] 2) According to DIN ISO 787 / XI, JIS K 5101 / 18 (not sieved)

[0143] 3) According to DIN ISO 787 / II, ASTM D 280, JIS K 5101 / 21

[0144] 4) According to DIN 55921, ASTM D 1208, JIS K 5101 / 23

[0145] 5) According to DIN ISO 787 / IX, ASTM D 1208, JIS K 5101 / 24

[0146] 6) According to DIN ISO 787 / XVIII, JIS K 5101 / 20

[0147] 7) Based on material dried at 105°C for 2 hours

[0148] 8) Based on a substance burned at 1000°C for 2 hours

[0149] 9) Special packaging to prevent moisture

[0150] 10) Water and ethanol are 1:1

[0151] 11) HCl content in combustion loss components

[0152] To make silica, volatile silicon compounds are sprayed into an oxyhydrogen gas flame of hydrogen and air. In most cases, silicon tetrachloride is used. This substance is hydrolyzed to silica and hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com