High-efficiency organic granulated fertilizer and preparation method thereof

A technology of organic granules and fertilizers, applied in the field of agricultural biology, can solve the problems of inability to solve the nutritional needs of crops, the products contain toxic and harmful substances, and the nutrient content of the products is not high, so as to achieve early market time, convenient and flexible application, and improve photosynthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The fertilizer of this embodiment is composed of the following raw materials and their weight percentages: molasses fermentation liquid: 78%, biochemical fulvic acid: 10%, base material: 12%; wherein, the base material is diamine hydrogen phosphate;

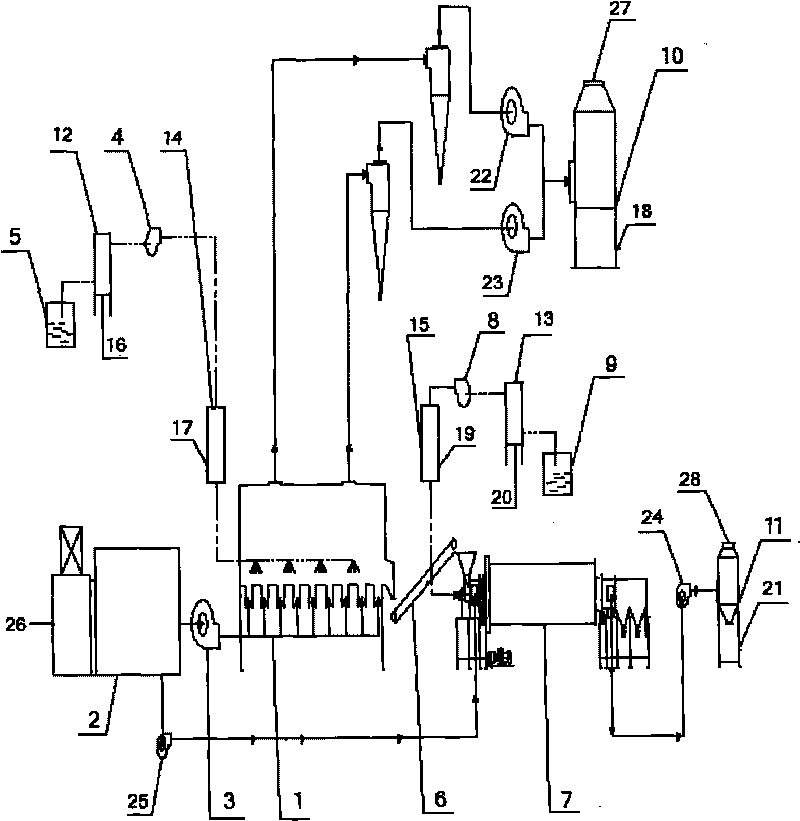

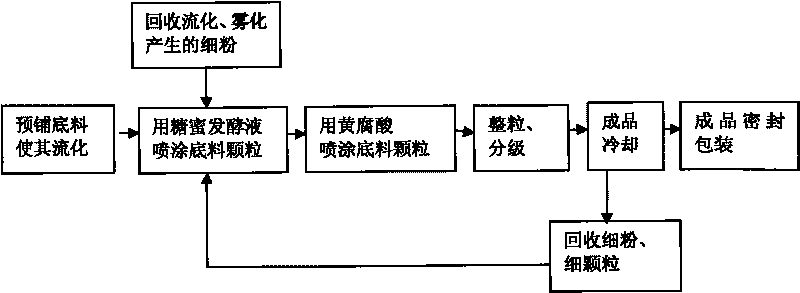

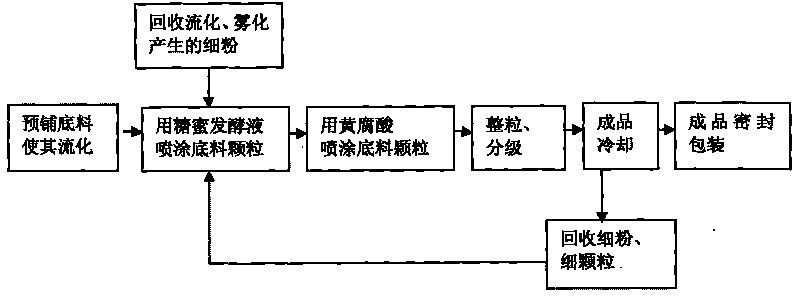

[0032] The preparation method of above-mentioned high-efficiency organic granular fertilizer comprises the following steps:

[0033] 1) Pre-lay the base material in the spray granulation fluidized bed 1, and the air is heated to 1200°C by the direct-fired coal-fired hot air stove 2, and then enters the bottom of the spray granulation fluidized bed 1 through the first hot air blower 3, and passes through the distribution plate Contact with the primer and make the primer fluidized.

[0034] 2) Utilize the first feed liquid pump 4 to deliver the molasses fermented liquid from the first feed liquid port 5 to the atomizing nozzle, make it sprayed on the surface of the bottom material particles in the fluidized state after atomi...

Embodiment 2

[0042] The difference between this example and Example 1 is that the weight percentages of raw materials used are different, and the preparation method is the same. The raw materials and their weight percentages are as follows: molasses fermented liquid: 10%, biochemical fulvic acid: 20%, base material: 70%, wherein, the base material is farmyard manure.

[0043] The organic matter content of the high-efficiency organic granular fertilizer obtained in this embodiment is 46%, the total content of nitrogen, phosphorus pentoxide, and potassium oxide is more than 8%, and the moisture content is 2.7%, which is far superior to the national organic fertilizer standard. The application tests of different crops prove that the effect of increasing yield and improving quality can reach the effect of Example 1, and the effect of this embodiment is more obvious for melons, fruits and vegetables.

Embodiment 3

[0045]The difference between this example and Example 1 is that the weight percentages of the raw materials used are different, the base material is the small particle fertilizer separated in Example 1 with a particle diameter within 2mm, and the preparation method is the same.

[0046] The raw materials and their weight percentages are as follows: molasses fermented liquid: 40%, biochemical fulvic acid: 40%, base material: 20%.

[0047] This embodiment can also achieve the effect of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com