Friction improver, preparation method and lubricating oil composition thereof

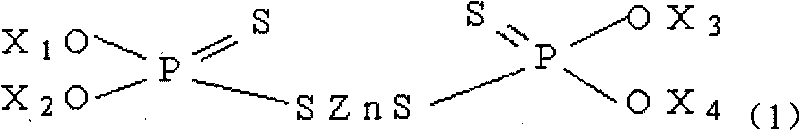

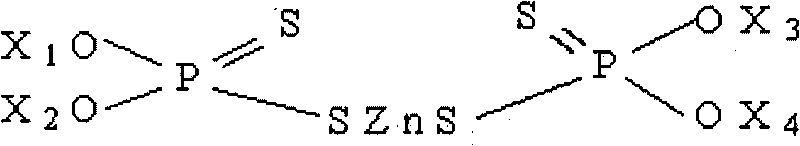

A technology of lubricating oil composition and friction modifier, applied in lubricating composition, additive, petroleum industry, etc., can solve the problems of dark color, poor compound effect of friction modifier and ZDDP, etc., and achieve the effect of expanding use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

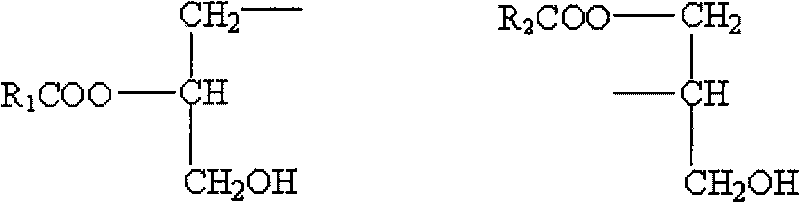

[0031] The preparation method of the friction modifier provided by the present invention comprises reacting fatty acid glycerides with phosphorus pentasulfide to obtain sulfuric acid products; then reacting the obtained phosphorus sulfuric acid products with zinc oxide and / or zinc hydroxide, wherein the fatty acid glycerides are One or more of the compounds shown in formula (7), formula (8), formula (9) and formula (10):

[0032]

[0033] Formula (7) Formula (8)

[0034]

[0035] Formula (9) Formula (10)

[0036] where R 7 , R 8 , R 9 , R 10 , R 11 and R 12 Each may be an alkyl group or an alkenyl group having 8 to 24 carbon atoms.

[0037] Preferably, R 7 , R 8 , R 9 , R 10 , R 11 and R 12 Each is an alkyl or alkenyl group with 12-18 carbon atoms.

[0038] The reaction temperature of the fatty acid glyceride and phosphorus pentasulfide can be 20-120° C., the reaction time can be 1-8 hours, and the weight ratio of phosphorus pentasulfide to fatty acid glyce...

Embodiment 1

[0054] This example is used to illustrate the preparation of the friction modifier of the present invention.

[0055] Add 500 grams of cottonseed oil, 300 grams of glycerin, and 4 grams of CaO into a 1000-ml three-neck flask, start stirring, raise the temperature to 200° C., and keep the temperature for 2 hours. Then lower the temperature to 60°C, separate and remove the precipitated glycerol, add 1mol / L hydrochloric acid to make the system acidic (pH value = 4), wash 3 times with water (each time with 300 ml of deionized water), and remove it with anhydrous sodium sulfate. After freeing moisture, keep it in an oven at 115°C for 3 hours. Then add 60 g P 2 S 5 , after reacting at 60 °C for 2 h, the excess P was filtered off 2 S 5 . 30 g of ZnO was added to the filtrate, the temperature was raised to 80° C. for 4 hours, and the precipitate was filtered off to obtain the target product, which was designated as A1. The zinc content of the product measured by the ICP method i...

Embodiment 2

[0057] This example is used to illustrate the preparation of the friction modifier of the present invention.

[0058] Add 500 grams of soybean oil, 180 grams of glycerin, and 4 grams of NaOH into a 1000-ml three-neck flask, start stirring, raise the temperature to 220°C, and keep the temperature for 4 hours. Then cool down to 60°C, separate the precipitated glycerol, add 1mol / L hydrochloric acid to make the system acidic (pH value = 4), wash with water 3 times (each time with 300 ml of deionized water), and remove free water with anhydrous sodium sulfate Afterwards, heat preservation in an oven at 115° C. for 3 hours. Then add 80 grams of P 2 S 5 , after reacting at 70 °C for 2 h, the excess P was filtered off 2 S 5 . Add 35 g of ZnO to the filtrate, raise the temperature to 80° C. and react for 4 hours, and filter off the precipitate to obtain the target product, which is designated as A2. The zinc content of the product measured by the ICP method inductively coupled pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com