Method for reducing ethylene cracking furnace tube coking and improving ethylene selectivity

An ethylene cracking furnace and furnace tube technology, which is applied in the directions of hydrocarbon cracking, gaseous chemical plating, coating, etc., can solve problems such as complex coating process, and achieve the effects of firm bonding, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

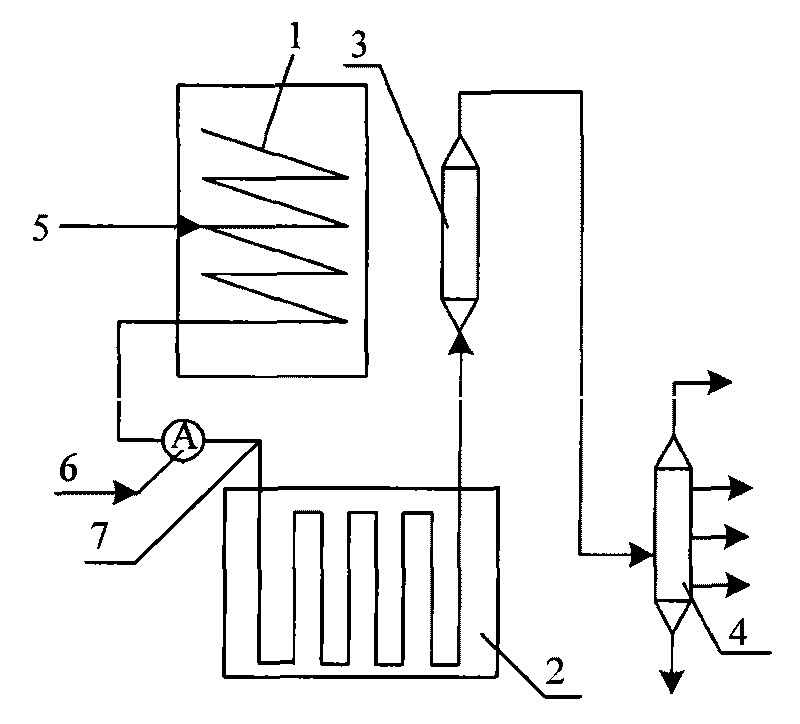

Method used

Image

Examples

Embodiment 1

[0030] The pre-coating of the furnace tube is carried out on the 200g / h laboratory ethylene cracking evaluation device, that is, vapor deposition. The pretreatment solution is injected from the connecting part of the preheater and the cracking furnace. The material of the furnace tube is 304 stainless steel, and the center of the furnace tube is inserted There are thermocouple protection tubes of the same material with the following dimensions:

[0031] Furnace tube size: 14×2×900mm; thermocouple protection tube: 6×1×850mm

[0032] (1) Vapor deposition

[0033]The conditions are as follows:

[0034] Preheater temperature: 600°C; cracking furnace temperature: 800°C; water vapor (carrier gas) flow rate: 50g / h; pretreatment solution injection rate: 8g / h (preheat and stir with a magnetic heating stirrer when injecting); Pretreatment solution: 2% ethanol solution of hexamethyldisiloxane;

[0035] (2) Heat treatment:

[0036] After vapor deposition, the temperature of the cr...

Embodiment 2

[0041] Replace the new furnace tube of the same material, change the pretreatment solution in the example 1 into the ethanol solution of 2 mass % hexamethyldisiloxane+2 mass % chromium acetylacetonate, other treatment conditions and processes are the same as in Example 1, The surface analysis results are shown in Table 2.

[0042] Table 2 furnace tube inner surface element data (wt%)

[0043] element

Embodiment 3

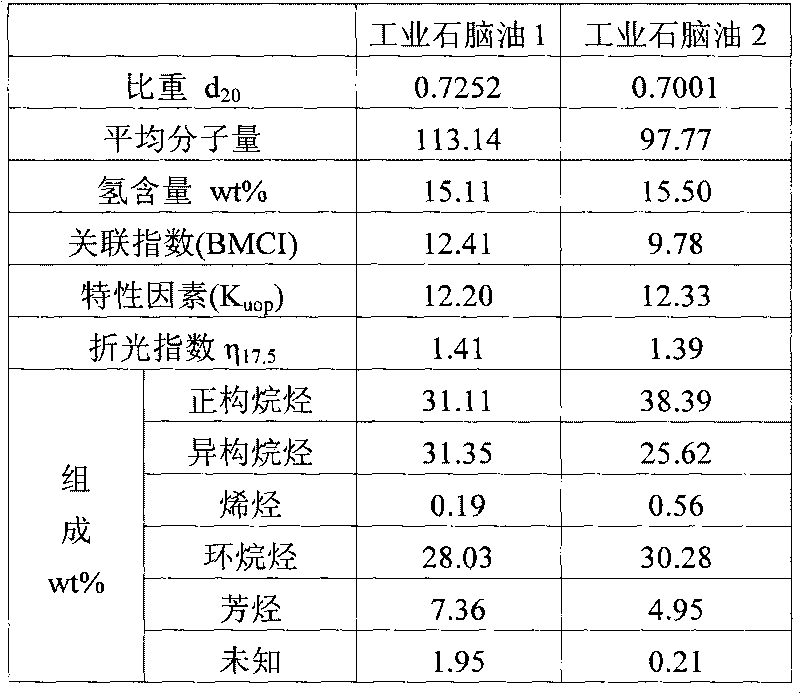

[0045] The furnace tube is processed according to the method described in Example 1, and then the cracking test is carried out on the device. In the cracking process, the cracked gas is analyzed by gas chromatography, and the nitrogen 2 and O 2 The mixed gas is burned, and the CO and CO in the burnt gas are measured online with an infrared analyzer 2 Concentration, the volume of charred gas is recorded online with a wet flowmeter, and the amount of carbon in the charred gas is calculated, that is, the coking amount of the furnace tube during the cracking operation cycle. The physical properties of the raw material oil used in the examples are shown in Table 4. The cracked gas was analyzed by gas chromatography, and it was found that the volume percentage of olefins was higher than that of the blank test. The comprehensive comparison of the specific results is shown in Table 5.

[0046] The cracking conditions are as follows:

[0047] Raw materials: 200 grams of industrial n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com