Silicon nitride ceramic ball bearing and processing method thereof

A silicon nitride ceramic ball and bearing technology, used in ball bearings, bearing components, shafts and bearings, etc., can solve the problems of rotational speed and temperature rise, life and bearing capacity, stiffness and vibration resistance, and noise can not be satisfied. Avoid heat accumulation into fatigue spalling failure, small elastic deformation and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

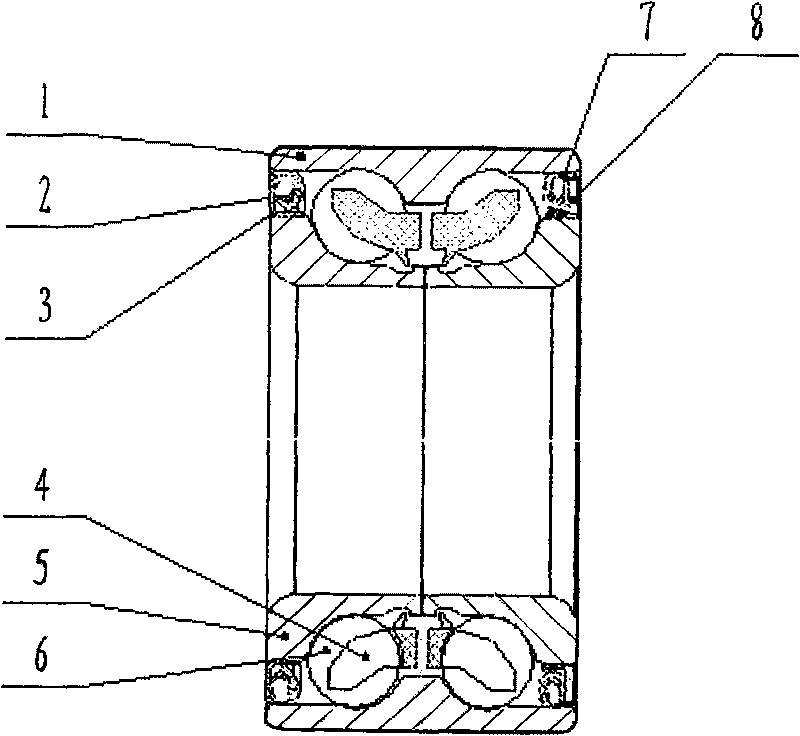

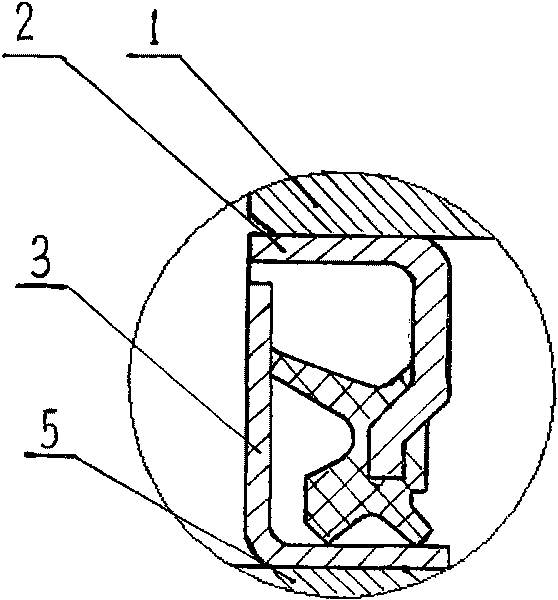

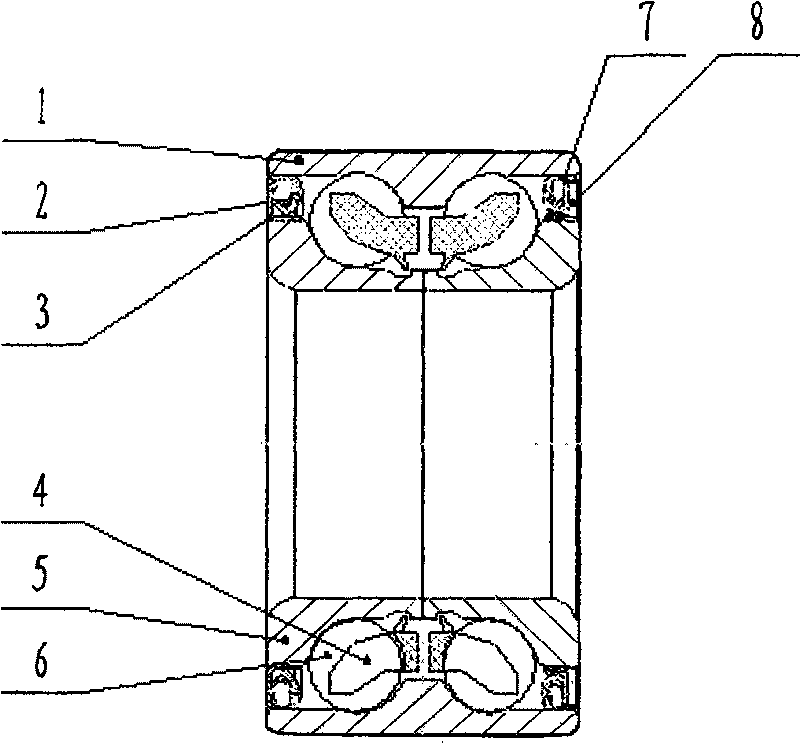

[0016] Such as figure 1 As shown, on the inner diameter of the outer ring 1 and the outer diameter of the inner ring 5 of the present invention, there are grooves with an elliptical or circular cross section at the contact parts with the rolling elements 6, and the torque passes through the grooves of the inner ring 1, The rolling element 6 and the groove of the outer ring 5 are used for transmission. There are two inner rings 5. The difference between the inner diameters of the two inner rings shall not exceed 0.004mm. The outer ring 1 and the inner ring 5 are made of bearing steel, which are cold-rolled, tempered , After rough and finish turning, carry out super-audio frequency surface quenching heat treatment, and then undergo isothermal tempering, rough grinding, fine grinding, and super-finish grinding. The problem of excessive impurities and impurities, the difficulty of controlling the depth of the transition layer and hardened layer of the workpiece, and the poor unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com