Lens used for optical module

A technology for optical modules and lenses, which is applied in the field of lenses for optical modules, can solve the problems of low optical properties of resins, reduced optical properties of lenses, and damage to the transparency of norbornene-based resins, and achieves resistance to reflow soldering processes and excellent durability. thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0110] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited by these examples.

[0111] In the following examples and comparative examples, the reflow resistance of the obtained lens-shaped molded article, the thickness ratio of the cured layer, the TMA heat distortion temperature of the cured layer, and the stress strain of the lens were measured or evaluated as follows, respectively.

[0112] (1) Resistance to reflow soldering

[0113] Using a reflow furnace (STR-2010N2M-III type) manufactured by Senju Metal Industry Co., Ltd., it implemented as follows.

[0114] (temperature setting)

[0115] The temperature setting of the reflow furnace is set as follows according to JEDEC standard J·STD·020D.

[0116] Conveyor belt speed: 25.3cm / min

[0117] Temperature setting for each heating zone

[0118] Zone 1: 305°C

[0119] Zone 2: 240°C

[0120] Zone 3: 240°C

[0121] Zone 4: 245°C

[0122] Zone 5...

manufacture example 1

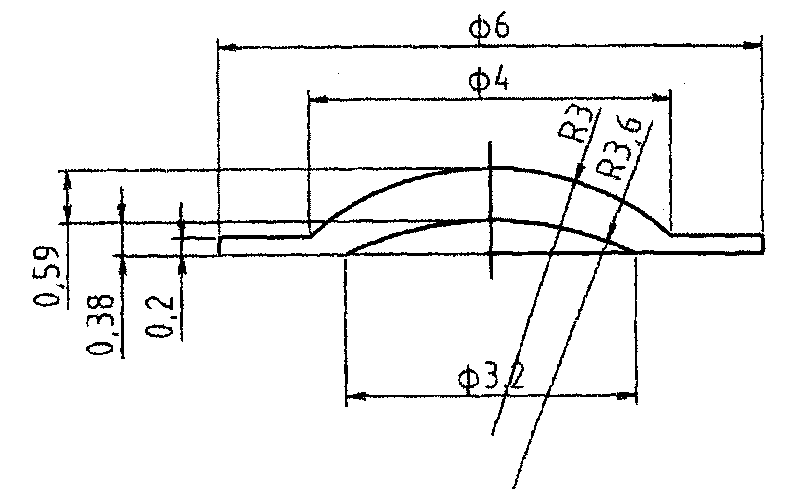

[0146] Using ARTON-F4520 (DSC-Tg: 160°C) manufactured by JSR Corporation as a cyclic olefin-based thermoplastic transparent resin, an injection molding machine (S-200i 50B manufactured by FANUC Corporation, cylinder diameter 22 mm, nozzle diameter 2.5 mm, clamping force 50 tons), injection molding according to the molding conditions shown in Table 1 figure 1 A lens for an optical module with a center thickness of 0.59mm is shown. In addition, the screw speed during metering is 25rpm, and the back pressure is 65kgf / cm 2 , The molding cycle is 50sec. Resin temperature indicates the maximum resin temperature in the barrel. Moreover, molding was performed 30 times after molding conditions were set, and the obtained lens was used as a product, and the molding (A) was obtained. The residual strain at the center of the molded body (A) was 43 MPa.

manufacture example 2

[0148] In Production Example 1, except that the cylinder temperature condition was changed so that the resin temperature was 310°C, it was performed in the same manner as Production Example 1, and injection molding was carried out under the molding conditions shown in Table 1. figure 1 Lenses shown with a center thickness of 0.59mm. After molding conditions were set, molding was performed 30 times, and the resulting lens was used as a product to obtain a molded body (B). The residual strain at the center of the molded body (B) was 101 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com