Integratable coupling microcavity optical filter

An optical filter and coupled microcavity technology, applied in the field of coupled microcavity optical filters, can solve problems such as increasing the processing difficulty of devices, and achieve the effects of reducing processing difficulty, reducing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

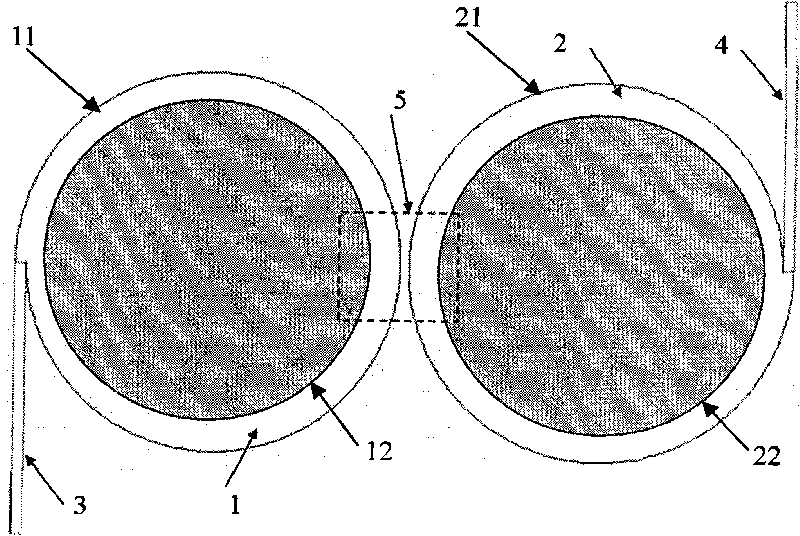

[0021] see figure 1 , the structure in the preferred embodiment of the present invention comprises spiral ring microcavity 1, spiral ring microcavity 2, input waveguide 3, output waveguide 4, coupling region 5; Two spiral ring microcavities are symmetrical, and spiral ring microcavity The outer ring 11 of 1 and the outer ring 21 of the spiral annular microcavity 2 automatically form gaps due to structural characteristics, the gap of the outer ring 11 of the spiral annular microcavity 1 is connected to the input waveguide 3, and the gap of the outer ring 21 of the spiral annular microcavity 2 is connected Output waveguide 4. The inner circle 12 of the spiral annular microcavity 1 and the inner circle 22 of the spiral annular microcavity 2 are circular. The outer ring 11 and the inner ring 12 are concentric, and the outer ring 21 and the inner ring 22 are concentric.

[0022] The principle and working method of the present invention are as follows: the helical annular microcav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com