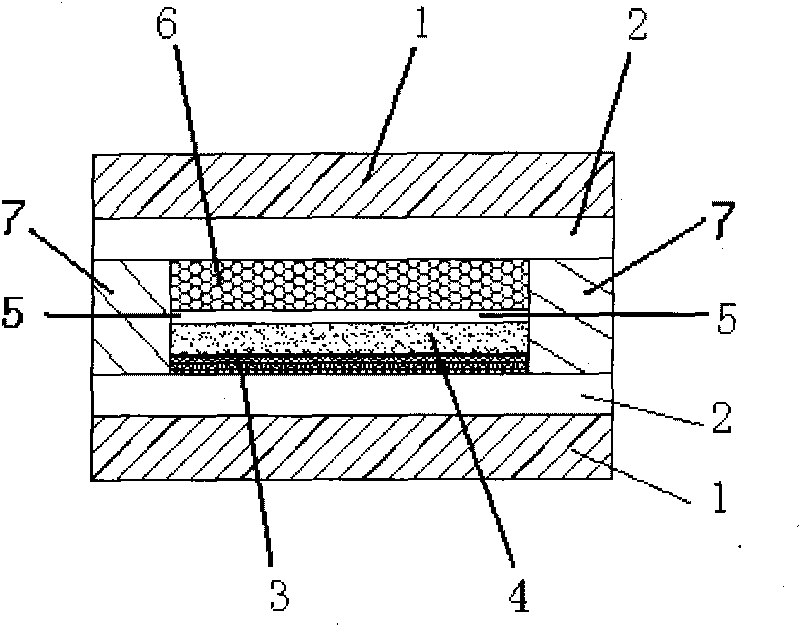

Method for preparing composite electrode of flexible dye-sensitized solar cell

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of increasing battery cost, high price, solvent volatilization, etc., and achieve the effects of easy film formation, low cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh PEDOT:PSS solution (US Sigma-Aldrich company, concentration 1.3% aqueous solution), polar solvent dimethyl sulfoxide, mix for 8 hours, add appropriate amount of carbon black powder, put into agate mortar and grind for 30 minutes, continue to stir 1-4h, raw material ratio weight according to Table 1. After making it fully mixed and volatilized, a slurry (colloidal) with a certain viscosity is obtained. Make it easy to form a film on the substrate. The final stirring time of the slurry is affected by the ambient temperature and stirring speed. Apply the prepared slurry on the conductive substrate by roller coating, and then dry it at room temperature under dust-free conditions. After the surface of the film is completely dry, put it in an oven at 80°C to dry to obtain the conductive polymer layer-PEDOT : PSS thin film counter electrode.

[0050] Table 1

[0051]

Embodiment 2

[0053] The experimental method is the same as in Example 1, and the proportioning weight of the raw materials is taken by weighing in Table 2. Preparation of conductive polymer layer-PEDOT:PSS thin film counter electrode.

[0054] Table 2

[0055]

Embodiment 3

[0057] As in Example 2, a conductive polymer layer-PEDOT:PSS film counter electrode was prepared. The composite electrode of the present invention can be obtained by coating a layer of quasi-solid electrolyte prepared by uniformly mixing the raw materials listed in Table 3 on the conductive polymer layer.

[0058] table 3

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com