Method for overlaying SiCp/Al composite material coating by melting pole inert-gas protective arc welding

A technology of inert gas and composite materials, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of easy cracking and peeling of the coating, high cost, etc., achieve low equipment cost, easy operation, improve heat resistance and The effect of vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

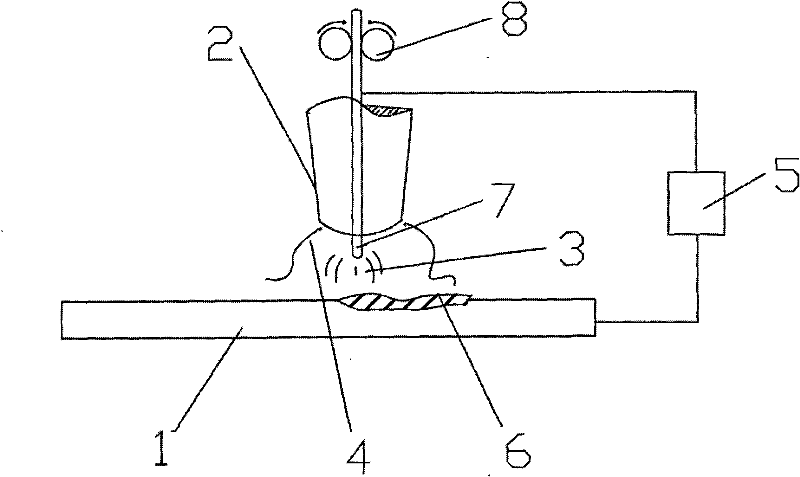

[0008] Specific embodiment one: in the present embodiment, the method for overlay welding SiCp / Al composite material cladding by MIGA welding is carried out according to the following steps: one, the aluminum alloy surface oxide film is removed, then use ethanol or acetone Clean and dry again; 2. Remove the oxide film on the surface of the welding wire, then clean it with ethanol or acetone, and then dry it in the air. The welding wire is a solid welding wire, which is composed of 3.5% to 12% SiC and 1.0% to 5.0% Ti by weight. , 0 ~ 1.0% B, 5.0% ~ 9.0% Si, 0 ~ 2.0% fluoride, 0 ~ 2.0% chloride and the rest of the Al composition; three, by MIG shielded arc welding (see figure 1 ) deposit the welding wire on the surface of the aluminum alloy; that is, obtain the SiCp / Al composite material coating on the surface of the aluminum alloy, wherein the MIG arc welding process conditions of step 3: the current form is direct current, adopting the reverse polarity connection method, weldin...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the welding wire described in step 2 is composed of 4% to 10% SiC, 2.0% to 4.0% Ti, 6.0% to 8.0% Si and the balance by weight. Al composition. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the welding wire in step 2 is composed of 5% to 9% SiC, 3% to 5.0% Ti, 0.1 to 1.0% B, 7.0% to 9.0% by weight. % Si and the balance Al composition. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com