Filter for fuel dispenser system

A filter and fuel dispenser technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of complex filter structure, difficult processing, poor quality reliability, etc., to save materials and processing costs, ensure crude oil quality, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

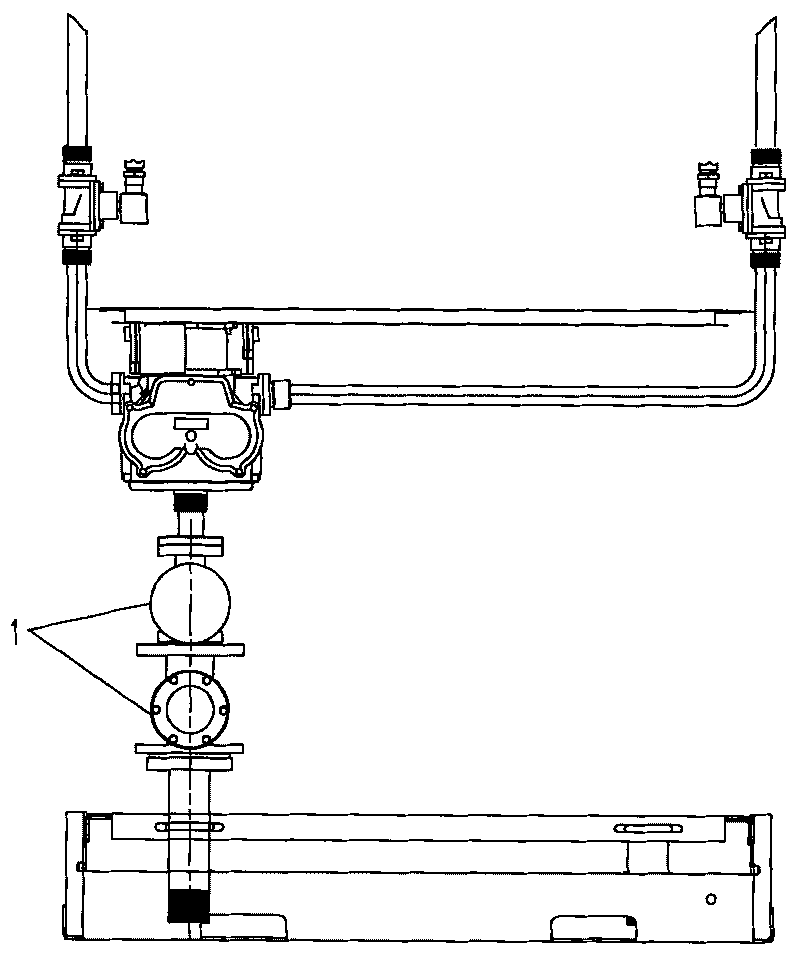

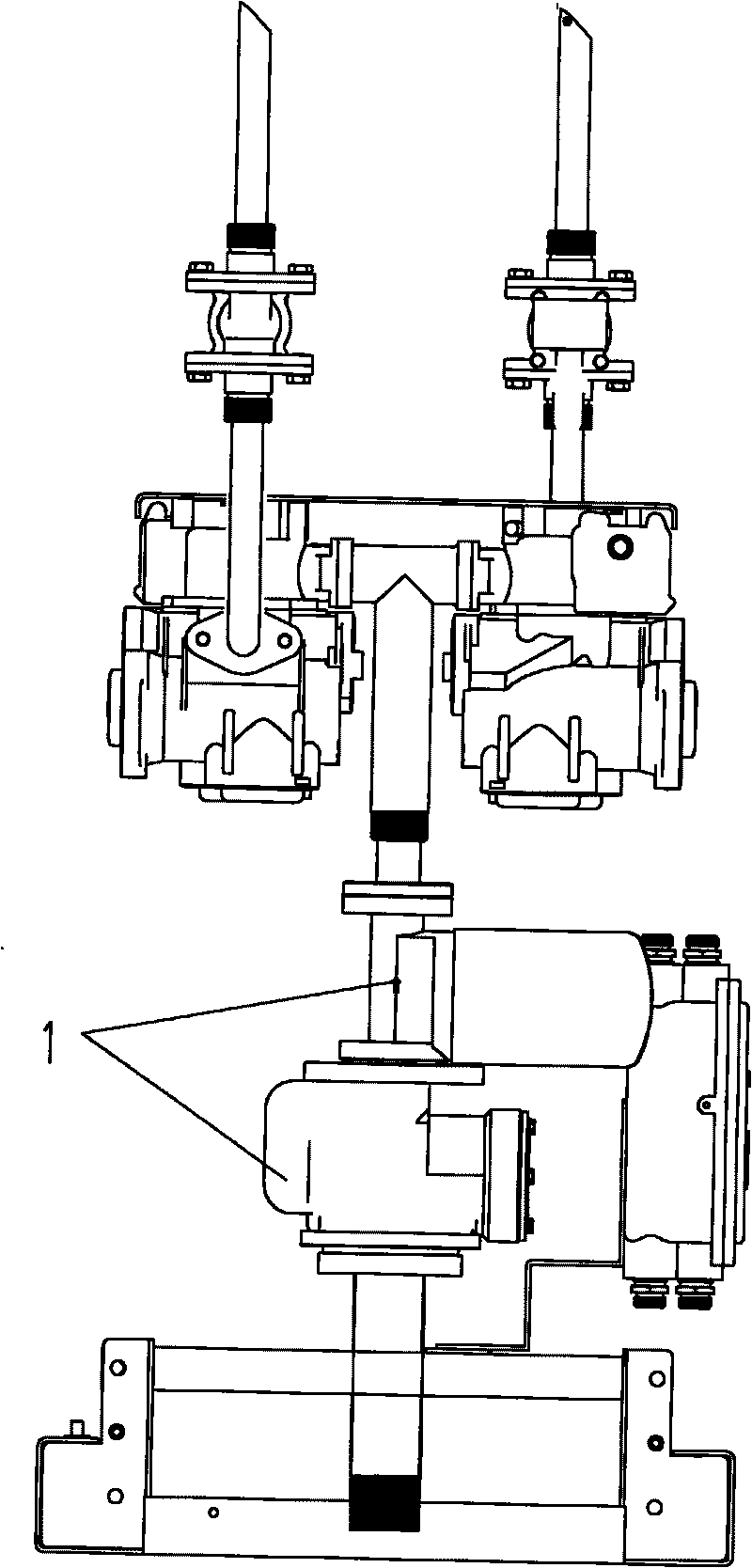

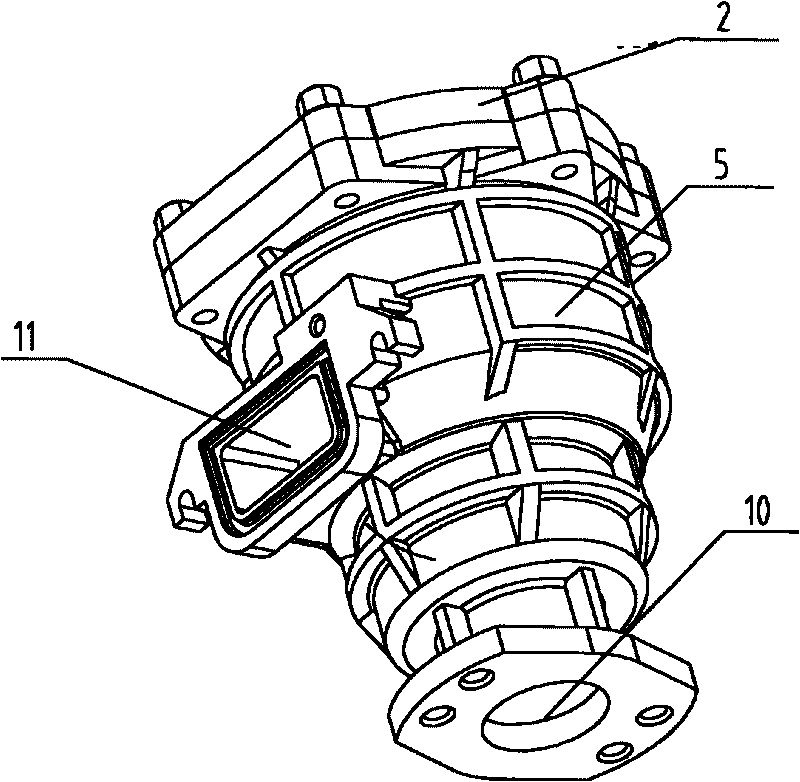

[0027] In this embodiment, a filter for a fuel dispenser system adopts a two-stage filter element for secondary filtration, and is applied to a fuel oil supply mode of a fuel oil machine supplied by a vacuum pump installed in the dispenser. Its external structure is as follows image 3 As shown, the internal structure is as Figure 4 As shown, it includes a filter body 5 and a filter cover 2 with a fluid inlet 10 and a fluid outlet 11; the inside of the filter body 5 is provided with at least two stages of filter elements, and the diameters of the filter elements at each level increase successively and are placed on the upper stage in turn. The periphery of the filter element, that is, the diameter of the secondary filter element 6 is greater than that of the primary filter element 7 and the secondary filter element 6 is placed on the periphery of the primary filter element 7; one end of the filter element is connected to the fluid inlet 10 of the filter body 5, and the filter ...

Embodiment 2

[0039] This embodiment is a filter for a fuel dispenser system, which uses a two-stage filter element for secondary filtration, and is applied to the fuel supply mode of a fuel oil dispenser supplied by a submersible pump installed in an oil tank. Compared with the first embodiment, the multifunctional filter of this embodiment is different in that the fluid inlet 10 of the filter body 5 does not need to be provided with a one-way valve 9, such as Figure 5 As shown, the multifunctional filter is used in the submersible oil pump 16, the filter can withstand repeated hydraulic shocks without leakage, and the fluid inlet 10 of the filter body 5 does not need to be provided with a one-way valve 9.

Embodiment 3

[0041] In this embodiment, a filter for a fuel dispenser system uses more than two stages of filter elements for multi-stage filtration. Can achieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com