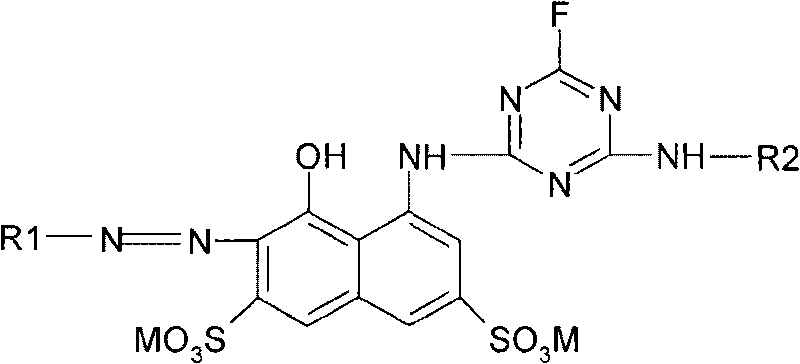

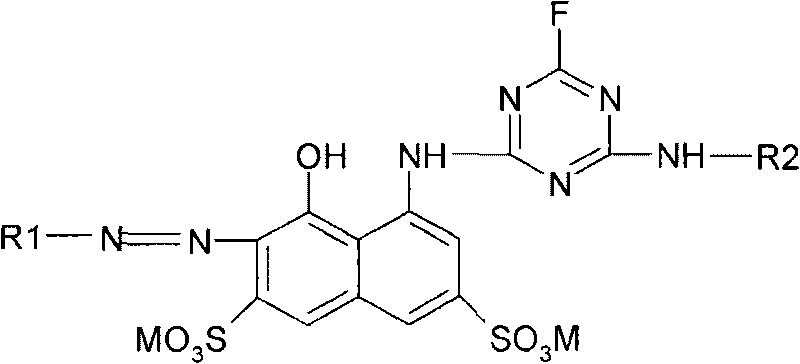

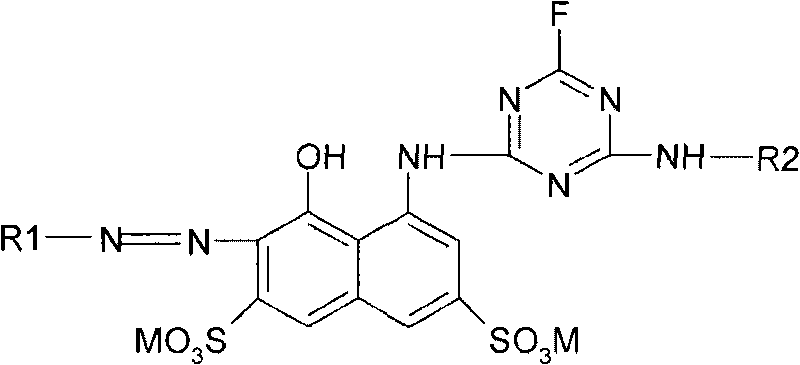

Red reactive dyes containing fluorotriazine and preparation method and application thereof

A reactive dye and red technology, applied in the field of dyes, can solve the problems of insufficient color fixation rate, poor compatibility, and high chroma of dyeing residual liquid, and achieve high color fixation rate, good environmental benefits, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 prepares the dyestuff, operates according to the following steps:

[0038] a, a condensation reaction

[0039] Put 1000 parts of bottom water in the dissolving pot, drop into 171 parts of 100% H acid for beating, and adjust pH=7.0 to material dissolution with 30% liquid caustic soda. Put 500 parts of bottom water and 500 parts of bottom ice into the condensation pot, put in 68 parts of cyanuric fluoride and beat for 30 minutes, and maintain T=0-5°C. Add the dissolved H-acid solution to the cyanuric fluoride solution, adjust the pH to 3.5-4.0 with baking soda dry powder, and use silicon plate chromatography to detect the end point after reacting for 2 hours. If the H-acid disappears and the end point is reached, a condensation liquid .

[0040] b. Secondary condensation reaction

[0041] Add 141 parts of 100% para-ester to the shrinkage liquid prepared in step a, raise the temperature to T=40°C, then adjust the pH=3.5-4.0 with baking soda dry powder, main...

Embodiment 2

[0049] Embodiment 2 prepares dyestuff, operates according to the following steps:

[0050] a, a condensation reaction

[0051] Put 1000 parts of bottom water in the dissolving pot, drop into 256 parts of 100% H acid for beating, adjust pH=7.0 to material dissolution with 30% liquid caustic soda. Put 800 parts of bottom water and 800 parts of bottom ice into the condensation pot, put in 101 parts of cyanuric fluoride and beat for 30 minutes, and maintain T=0-5°C. Add the dissolved H-acid solution to the cyanuric fluoride solution, adjust the pH to 3.5-4.0 with baking soda dry powder, and use silicon plate chromatography to detect the end point after reacting for 2 hours. If the H-acid disappears and the end point is reached, a condensation solution .

[0052] b. Secondary condensation reaction

[0053] Add 211 parts of 100% meta-ester to the shrinkage solution prepared in step a, raise the temperature to T=40°C, then use dry baking soda powder to adjust the pH=3.5-4.0, maint...

Embodiment 3

[0061] Embodiment 3 prepare dye, operate according to the following steps:

[0062] a, a condensation reaction

[0063] Put 1000 parts of bottom water in the dissolving pot, drop into 341 parts of 100% H acid for beating, and adjust pH=7.0 to material dissolution with 30% liquid caustic soda. Put 1000 parts of bottom water and 1000 parts of bottom ice into the condensation pot, put in 135 parts of cyanuric fluoride and beat for 30 minutes, and maintain T=0-5°C. Add the dissolved H-acid solution to the cyanuric fluoride solution, adjust the pH to 3.5-4.0 with baking soda dry powder, and use silicon plate chromatography to detect the end point after reacting for 2 hours. If the H-acid disappears and the end point is reached, a condensation solution .

[0064] b. Secondary condensation reaction

[0065] Add 281 parts of 100% para-ester to the shrinkage solution prepared in step a, raise the temperature to T=40°C, then use dry baking soda powder to adjust the pH=3.5-4.0, mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com